Method for preparing drag reducer from modified MoS2

A drag reducer and modification technology, which is applied in the field of preparation of drag reducer based on modified MoS2, can solve the problems of limited water solubility, limited temperature resistance, and long time consumption, and achieve good water solubility and sand carrying capacity. The effect of increased reaction speed and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

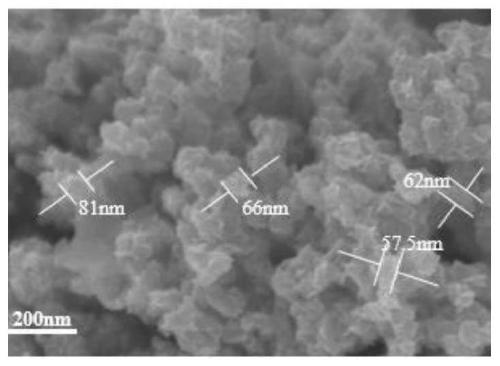

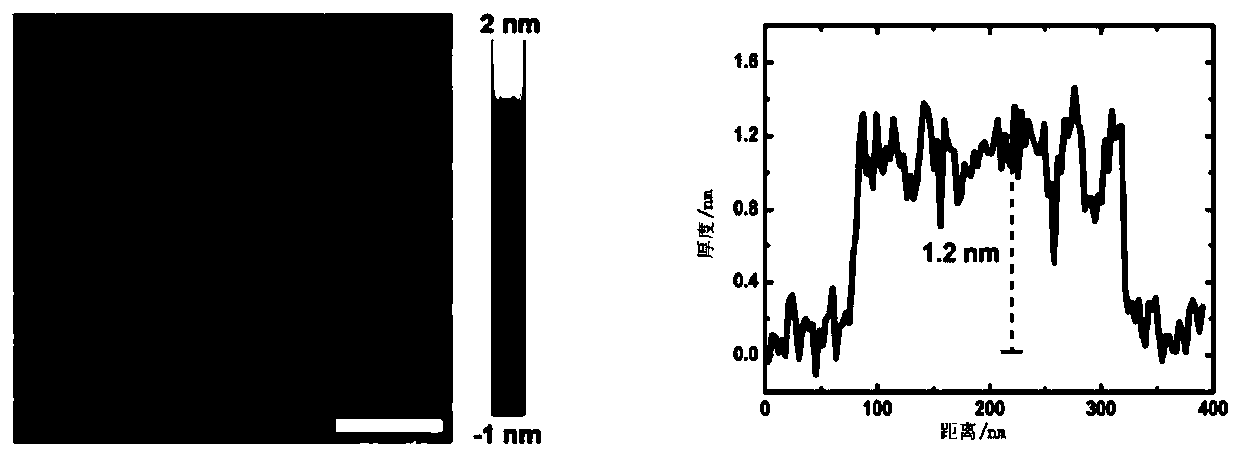

[0042] (1) Hydrophilic MoS 2Preparation of nanosheets: Dissolve hexammonium heptamolybdate and thiourea (molar ratio 1:7) in 35mL deionized water, then autoclave at 220°C for 18h, after the solution is cooled to room temperature, wash twice with water and wash with ethanol. Twice, washed once with water, and dialyzed against ultrapure water to remove unreacted reagents and impurities.

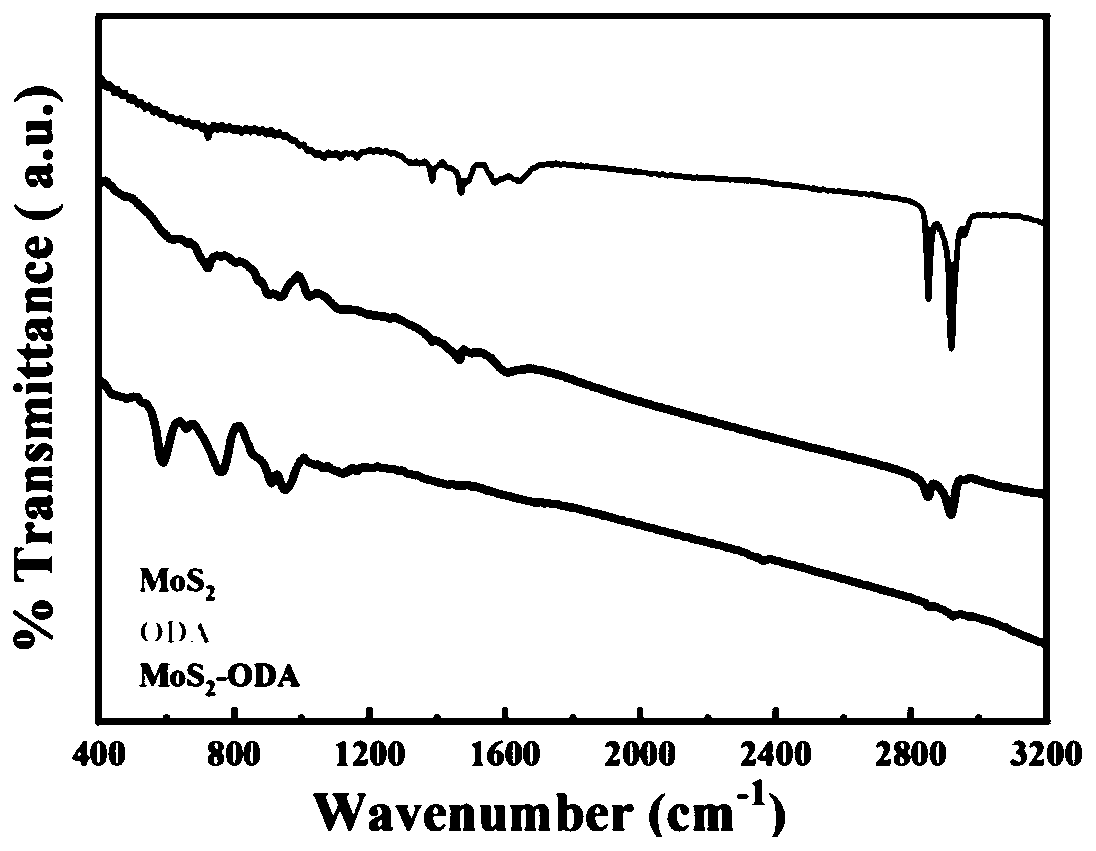

[0043] (2) Modified MoS 2 Preparation of ODA: add 0.25g ODA to 50mL deionized water, and ultrasonically dissolve ODA for 10min; add 2.5g hydrophilic MoS to another 50mL deionized water 2 Nanosheets, sonicated for 30min to make hydrophilic MoS 2 The nanosheets were fully dispersed and presented a monolayer state; finally, the ODA solution was slowly added to the hydrophilic MoS under ultrasonic conditions. 2 In the nanosheet dispersion, continue to sonicate the compound solution for 30 minutes; then pour the obtained mixture into a flat-bottomed flask, stir for 12 hours at a rotation speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com