Polyurethane white paint as well as preparation method and application thereof

A polyurethane and white paint technology, applied in the field of coatings, can solve the problems of low whiteness and easy yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Correspondingly, on the basis of the formula of the polyurethane white paint of the above-mentioned embodiment of the present invention, the embodiment of the present invention also provides a preparation method of the polyurethane white paint. In one embodiment, the preparation method of the polyurethane white paint specifically comprises the following steps:

[0029] Step S01: weighing each component according to the above polyurethane white paint formula;

[0030] Step S02: mixing the weighed alkyd resin, dispersant, defoamer, titanium dioxide, fluorescent whitening agent, propylene glycol methyl ether acetate and butyl acetate, and then grinding;

[0031] Step S03: Mixing the material ground in step S02 with matting powder, anti-settling agent and leveling agent.

[0032] Specifically, the formula components of the polyurethane white paint weighed in the above step S01 are the same as the formula components of the polyurethane white paint mentioned above, and for t...

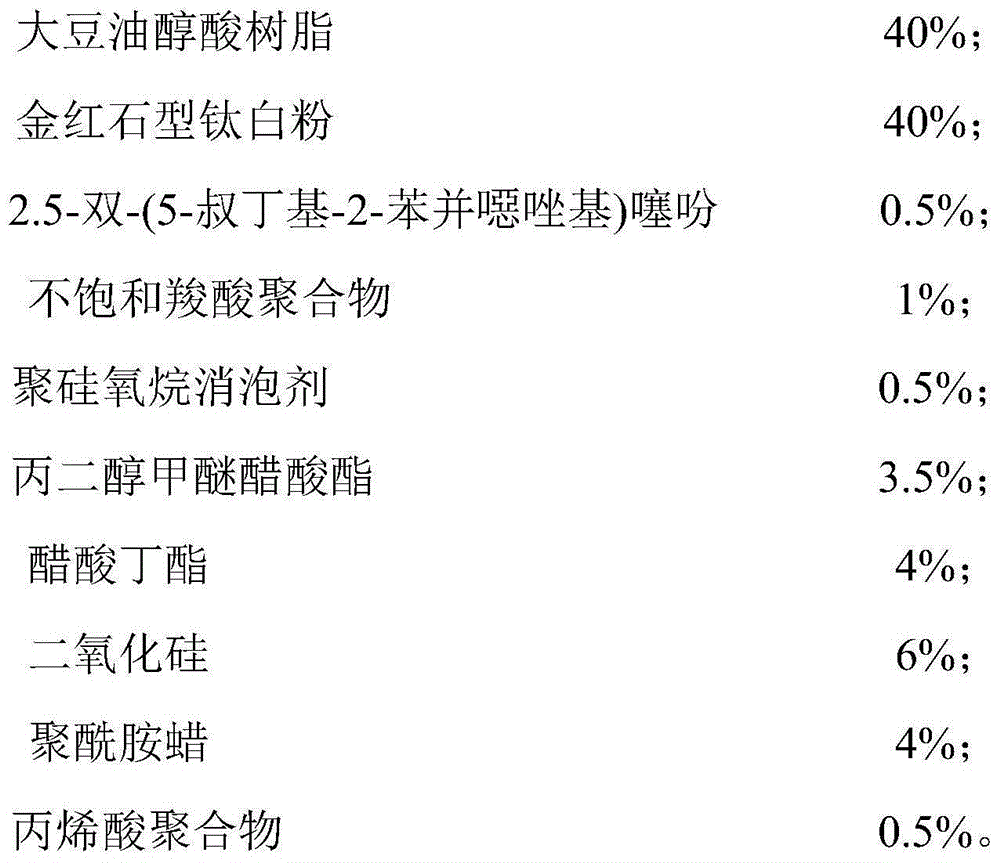

Embodiment 1

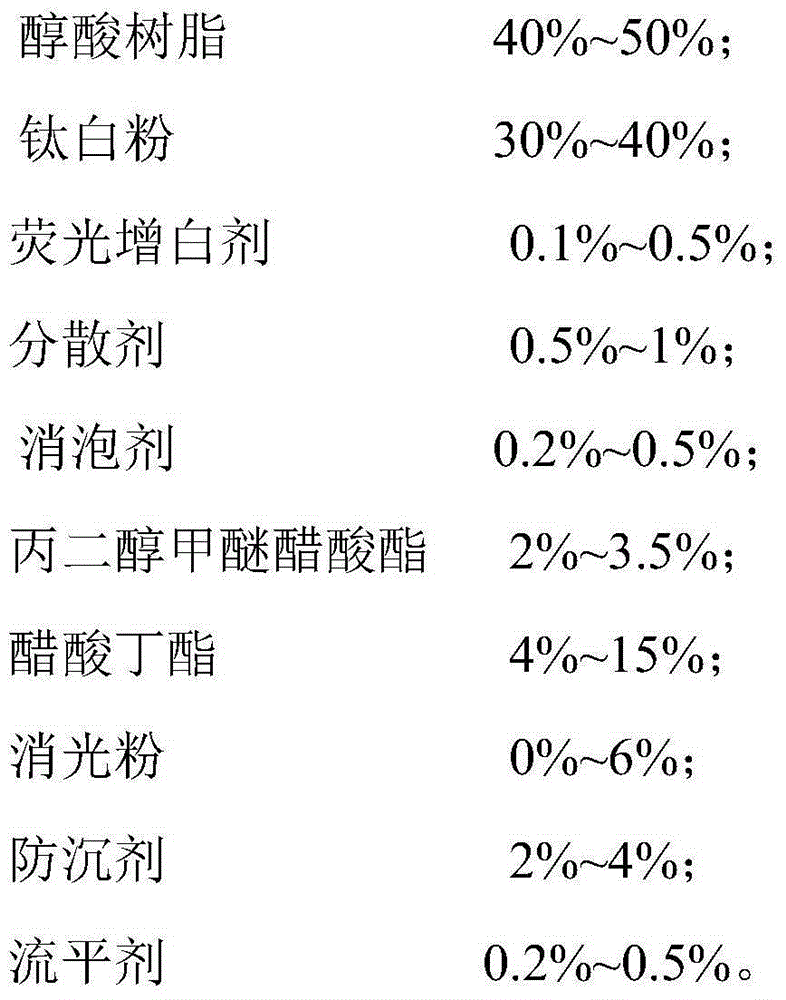

[0041] A polyurethane white paint and a preparation method thereof. Wherein, polyurethane white paint is made of the following components by weight:

[0042]

[0043] The preparation method of this polyurethane white paint comprises the steps:

[0044] Step S01, according to the weight of each component provided in Example 1, add the soybean oil alkyd resin weighed into the manufacturing tank, and gradually add unsaturated carboxylic acid polymer, 2.5-bis -(5-tert-butyl-2-benzoxazolyl)thiophene, continue to stir for 10min;

[0045] Step S02, increase the stirring speed to 200rpm / min, gradually add rutile titanium dioxide, 2.5-bis-(5-tert-butyl-2-benzoxazolyl)thiophene, propylene glycol methyl ether acetate and butyl acetate, keep Continue to stir and disperse for 10 minutes at a speed of 200rpm / min, and then grind on a sand mill to control the grinding fineness so that the fineness of the ground material is ≤15um;

[0046] Step S03, continue to stir the ground material a...

Embodiment 2

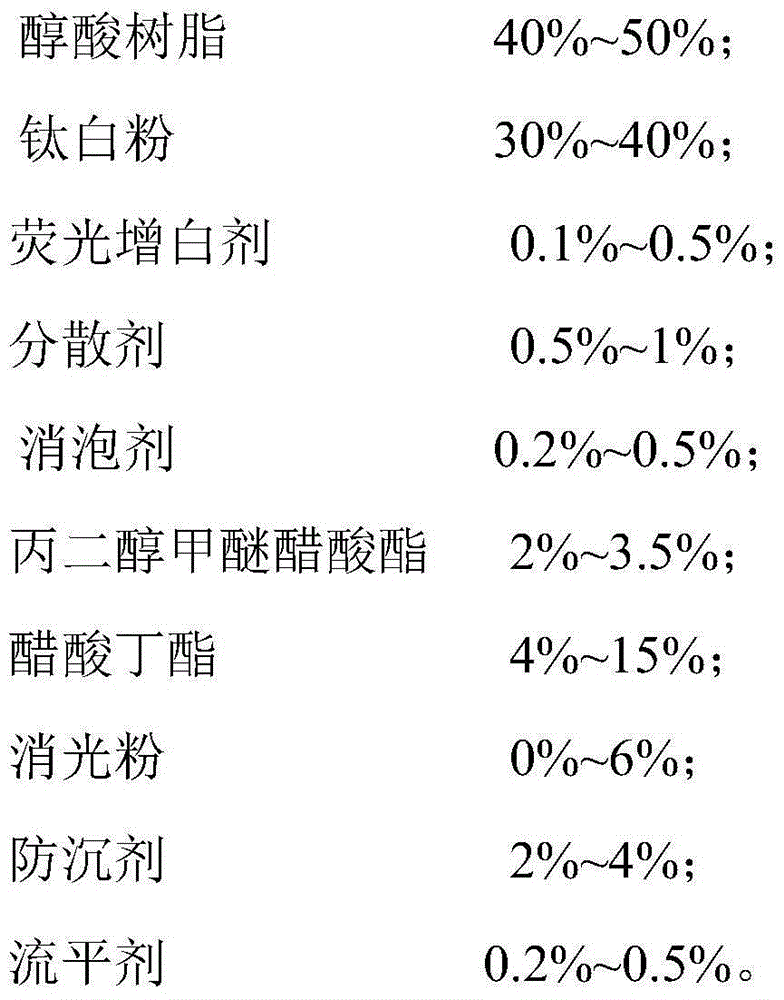

[0050] A polyurethane white paint and a preparation method thereof. Wherein, polyurethane white paint is made of the following components by weight:

[0051]

[0052]

[0053] The preparation method of this polyurethane white paint comprises the steps:

[0054] Step S01, according to the weight of each component provided in Example 1, add the soybean oil alkyd resin weighed into the manufacturing tank, and gradually add unsaturated carboxylic acid polymer, 2.5-bis -(5-tert-butyl-2-benzoxazolyl)thiophene, continue to stir for 15min;

[0055] Step S02, increase the stirring speed to 300rpm / min, gradually add rutile titanium dioxide, 2.5-bis-(5-tert-butyl-2-benzoxazolyl)thiophene, propylene glycol methyl ether acetate and butyl acetate, keep Continue to stir and disperse at a speed of 300rpm / min for 12 minutes, then grind on a sand mill to control the grinding fineness so that the fineness of the ground material is ≤15um;

[0056] Step S03, continue to stir the ground ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com