Superfine water-based pigment ink and manufacturing method thereof

A technology for water-based pigments and a manufacturing method, applied in the field of pigment inks, can solve problems such as application limitations of pigment inks, and achieve the effect of good dispersion stability

Active Publication Date: 2013-11-27

SHANGHAI NNW NEW MATERIALS TECH

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Based on the influence of these factors, the application of pigment ink is limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

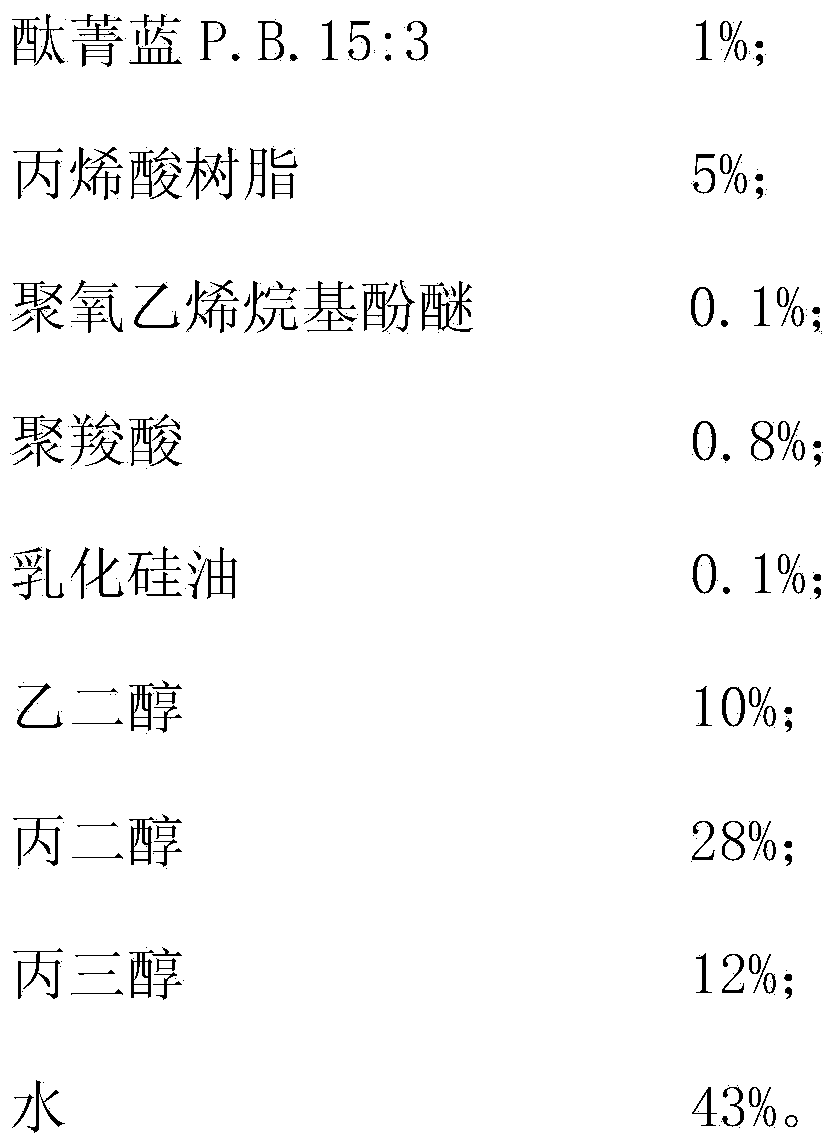

Embodiment 1

[0039]

Embodiment 2

[0041]

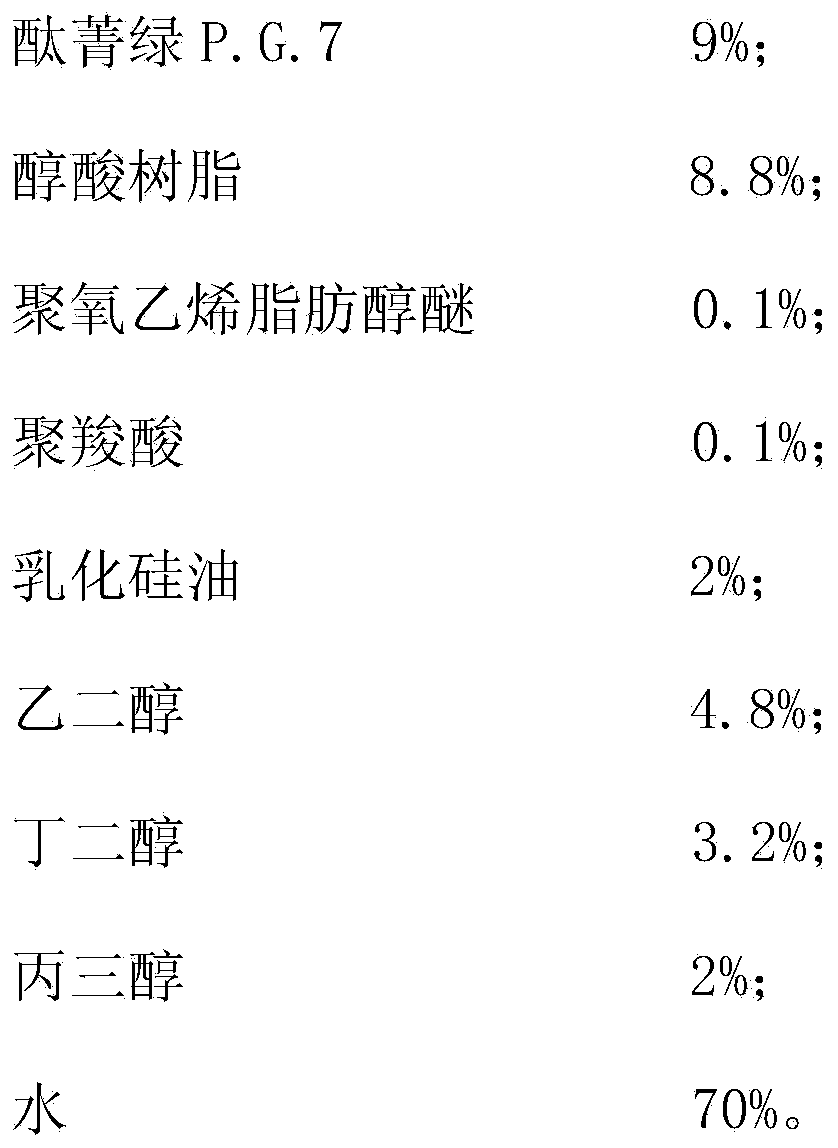

Embodiment 3

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

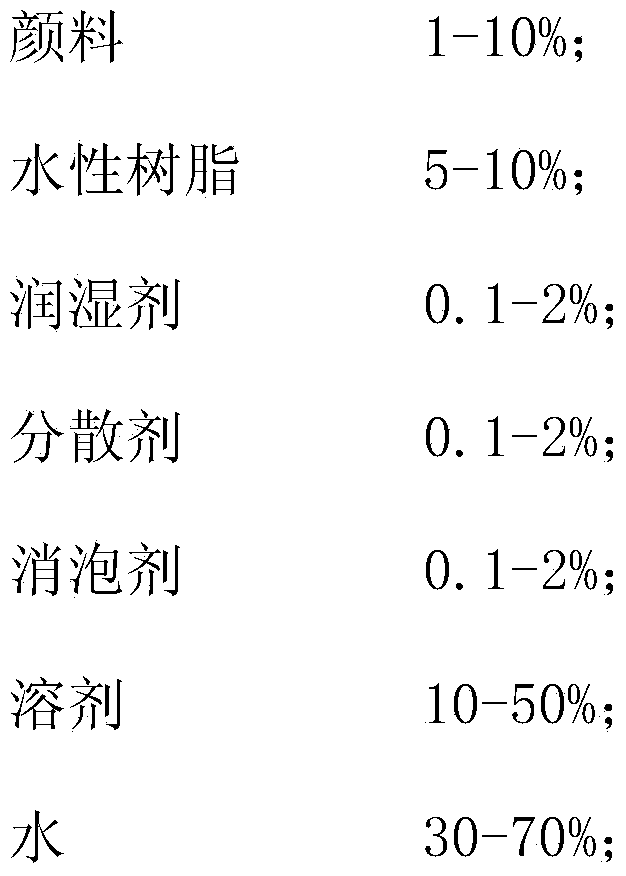

The invention relates to superfine water-based pigment ink and a manufacturing method thereof. The superfine water-based pigment ink is suitable for high-requirement pens for writing and printers and comprises the following components in weight percent: 1% to 10% of pigment, 5% to 10% of water-based resin, 0.1% to 2% of wetting agent, 0.1% to 2% of dispersant, 0.1% to 2% of foam killer, 10% to 50% of resolvent and 30% to 70% of water, wherein as different kinds of pigment can be used, the particle diameter of the pigment ranges from 40 nm to 80 nm. The manufacturing technique comprises the steps of shearing and dispersing, high-pressure collision, multi-stage sanding and ink compounding. The ink provided by the invention flows out smoothly and is high in storage stability; a manufactured writing pen can be still used normally after being transported at high temperature for a long time.

Description

technical field [0001] The invention relates to a pigment ink, in particular to an ultrafine water-based pigment ink and a manufacturing method thereof. Background technique [0002] Water-based inks are divided into water-based dye inks and water-based pigment inks according to their color properties. The advantage of the dye-based ink is that the dye is dissolved in water, and the ink of the writing pen is smooth, easy to manufacture, and low in cost. The disadvantage is that the ink is not water-resistant and light-resistant. For pigment-based inks, the pigments are highly dispersed in the medium, which overcomes the characteristics of dye-based inks that are not resistant to water and light. However, mechanical sanding of the pigments is required during manufacture, and the manufacturing process requires high requirements. Ordinary water-based pigment inks have large particle sizes and low stability, and are prone to precipitation and particle aggregation and flocculati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D11/16C09D11/10

Inventor 钱皓贾立夏

Owner SHANGHAI NNW NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com