Glycol-based pigment dispersoid for dacron stock solution coloring and preparation method of dispersoid

A technology for pigment dispersion and dope coloring, applied in dyeing, textile and paper making, etc., to achieve the effect of small particle size, narrow particle size distribution and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

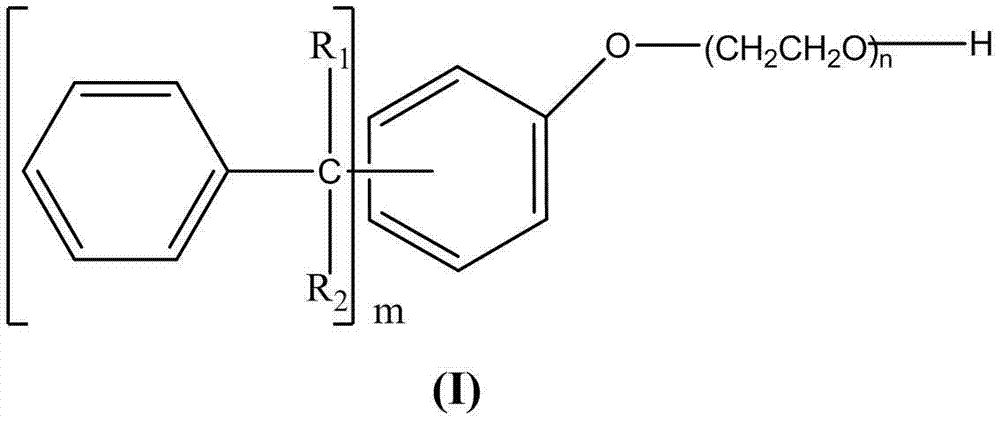

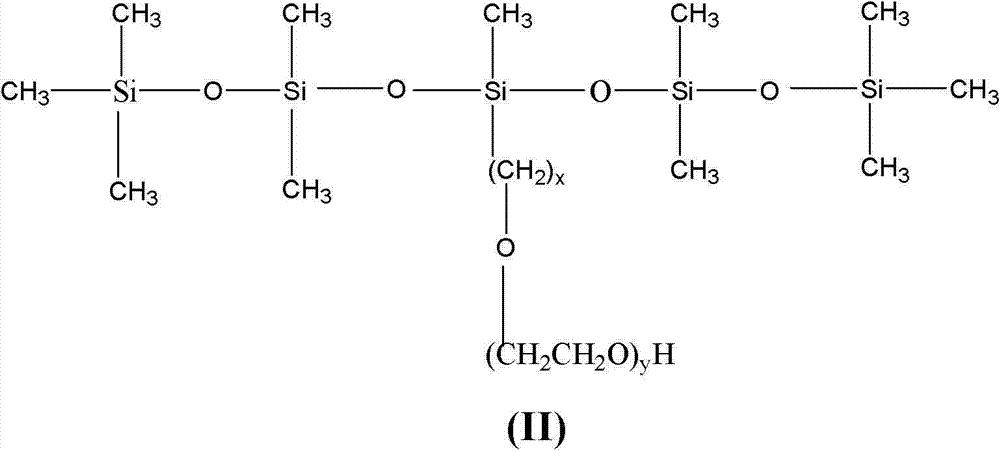

Method used

Image

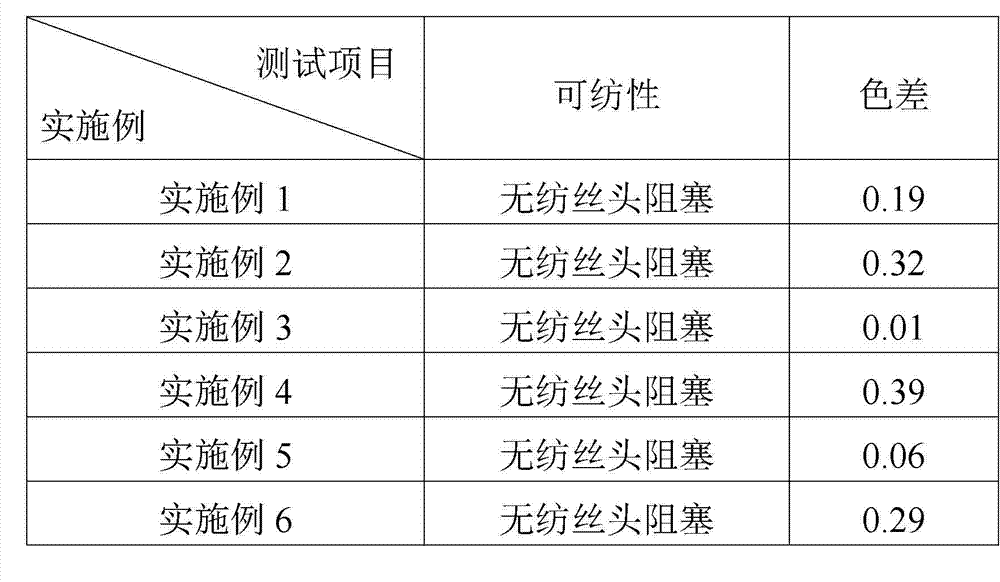

Examples

Embodiment 1

[0040] Dissolve 40g of wetting agent A and 60g of dispersant C in the ethylene glycol of supplementary amount, add 400g of carbon black in the solution, emulsify and pre-disperse for 0.5 hour with the speed of 300 ~ 400 rev / min on the high-speed emulsifying machine, obtain the pre-dispersion Dispersion liquid, put the pre-dispersion liquid in a sand mill for grinding and dispersing, the grinding time is 1 hour, filter the ground pigment dispersion through a 1000nm microporous membrane to remove coarse particles and impurities in the dispersion, and obtain Ethylene glycol-based carbon black pigment dispersion with an average particle size of 160nm.

Embodiment 2

[0042] Dissolve 45g of wetting agent A and 180g of dispersant B in the supplementary amount of ethylene glycol, add 900g of phthalocyanine blue 15:3 pigment, and emulsify and pre-disperse for 2 hours at a speed of 300~400 rpm on a high-speed emulsifier to obtain Pre-dispersion, put the pre-dispersion in a sand mill for grinding and dispersing, the grinding time is 8 hours, filter the ground dispersion through a 1000nm microporous membrane, remove coarse particles and impurities, and obtain the average particle size A 120nm dispersion of ethylene glycol based phthalocyanine blue 15:3 pigment.

Embodiment 3

[0044] Dissolve 60g of wetting agent C and 100g of dispersant B in the supplementary amount of ethylene glycol, add 2000g of titanium dioxide, and emulsify the pre-dispersion on a high-speed emulsifier at a speed of 300-400 rpm for 3 hours to obtain a pre-dispersion. The pre-dispersion is placed in a sand mill for grinding and dispersing. The grinding time is 0.5 hours. The ground dispersion is filtered through a 1000nm microporous membrane to remove coarse particles and impurities, and obtain a acetic acid with an average particle size of 73nm. Glycol-based titanium dioxide pigment dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com