Modified milk for milky tea, preparation method and application thereof

A technology for preparing milk and milk tea, which is applied in applications, milk preparations, dairy products, etc. It can solve the problems of acid resistance of the prepared milk, thin taste of milk tea, and insufficient milk aroma, etc., and achieves easy operation, outstanding tea taste and milk fragrance full-bodied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

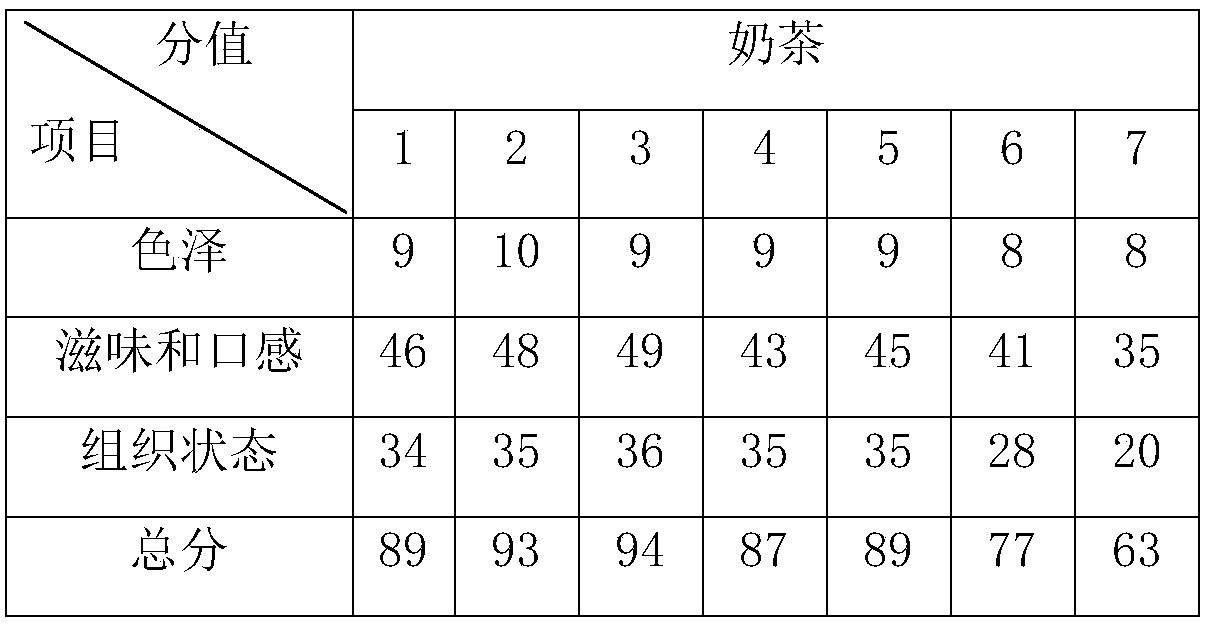

Embodiment 1

[0048] A method for preparing milk for milk tea, the method comprising the steps of:

[0049] (1) Concentration of raw milk: Pasteurize the raw milk at 75°C for 16-18s, and then concentrate it through the RO membrane. The concentration ratio is 1.5 times to obtain concentrated milk;

[0050] (2) Put 600kg of concentrated milk into the tank, add 27kg of cream and mix to obtain mixture a;

[0051] (3) Preheat the mixture a obtained in step (2) to 50-70°C, add 0.5 kg of sucrose fatty acid ester, 0.8 kg of monoglyceride fatty acid ester, 0.2 kg of sodium carboxymethyl cellulose, microcrystalline cellulose Dissolve 1.5kg, 0.2kg of carrageenan, 0.1kg of guar gum, and 0.1kg of phosphate, add water to 1000kg, and stir evenly;

[0052] (4) After the material is heated to 65°C, it is homogenized, and the homogenization pressure is 20MPa;

[0053] (5) Sterilization: The homogenized material is sterilized by a UHT sterilizer, and the sterilization condition is 137-142°C for 3-5 seconds;...

Embodiment 2

[0061] A method for preparing milk for milk tea, the method comprising the steps of:

[0062] (1) Concentration of skim milk: Pasteurize the skim milk at 75°C for 16-18 seconds, and then concentrate it through the RO membrane. The concentration ratio is about 1.7 times to obtain concentrated skim milk;

[0063] (2) Put 770 concentrated skim milk into the tank, add 140kg of cream and mix;

[0064] (3) After heating up the mixed material to 50-60°C, add 0.25 kg of sodium carboxymethyl cellulose, 2.6 kg of microcrystalline cellulose, 0.2 kg of carrageenan, 0.15 kg of guar gum, 0.2 kg of pectin, and xanthan Glue 0.3, sodium alginate 0.3, phosphate 0.3kg, sucrose fatty acid ester 0.6kg, monoglyceride fatty acid ester 1.0kg, soybean lecithin 0.4kg, Tween 80 0.2kg, sodium stearoyl lactylate 0.4kg, diacetyl tartaric acid bis Glyceride 0.4kg, lactic acid fatty acid glyceride 1.0kg, stir for 10-15min until completely dissolved, then add water to 1000kg;

[0065] (4) After the material...

Embodiment 3

[0076] A method for preparing milk for milk tea, the method comprising the steps of:

[0077] (1) Concentration of raw milk: Pasteurize the raw milk at 75°C for 16-18s, and then concentrate it through the RO membrane. The concentration ratio is about 2 times to obtain concentrated milk;

[0078] (2) Mix 800kg of concentrated milk with 40kg of cream, preheat the mixture to 60°C, add 0.8kg of sucrose fatty acid ester, 1.2kg of monoglyceride fatty acid ester, 0.3kg of sodium carboxymethylcellulose, and microcrystalline cellulose Dissolve 2kg of prime, 0.15kg of carrageenan, and 0.1kg of phosphate, stir for 10-15min until completely dissolved, then add water to 1000kg;

[0079] (3) After the material is further heated to 70°C, it is homogenized, and the homogenization pressure is 12MPa;

[0080] (4) Sterilization: The homogenized material is sterilized by a UHT sterilizer, and the sterilization condition is 137-142°C for 3-5 seconds;

[0081] (5) Packaging: The sterilized materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com