Method for preparing lutein water-soluble dry powder

A lutein and water-soluble technology, applied in the field of preparation of food-grade lutein water-soluble dry powder, can solve the problems of embedded protection of lutein crystals, difficult to operate, and high requirements for operating conditions, and achieves physical stability and Good chemical stability, good coloring and nutritional enhancement, and the effect of increasing the content of all-trans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Fully mix 30g of lutein crystals and 650g of acetone in a 1000ml three-necked bottle, then add 6.0g of mixed tocopherols and 3.0g of sorbitan fatty acid ester, mix well, heat the mixture to 60°C and dissolve it for 0.5hr. Get an oily phase. 75.0 g of modified starch and 136.0 g of glucose were dissolved in 600 ml of deionized water at 80° C. for 0.5 hr, then cooled down to 40° C. for use.

[0030] Under high-speed shearing, the oil phase is slowly added to the water phase to mix and emulsify, and then the emulsion is uniformly passed through a high-pressure homogenizer, the pressure used is 45MPa, and the homogenization is performed twice to make the final emulsion particle size reach about 250nm. The organic solvent acetone and part of the water are evaporated under reduced pressure, so that the solid content in the final emulsion is about 40%, and most of the remaining water is removed by spray drying, and the emulsion is turned into dry powder particles.

[0031] Fi...

Embodiment 2

[0033] Fully mix 18kg of lutein crystals and 450kg of ethyl acetate in a reaction kettle, then add 10kg of mixed tocopherols, 5.0kg of ascorbyl palmitate, and 8.0kg of sunflower oil, mix well and stir to dissolve at 80°C for 0.5hr. A clear, transparent solution was formed as an oily phase. Disperse 75.0kg of modified starch in 200kg of water, add 120.0kg of sucrose, dissolve completely at 80°C after mixing, cool to 45°C, and use it as the water phase for later use.

[0034] Under the condition of high-speed shearing, the oil phase is slowly added to the water phase to mix and emulsify, and then the emulsion is homogenized through a high-pressure homogenizer, the pressure used is 60MPa, and the homogenization is performed twice to make the final emulsion particle size reach about 170nm. The organic solvent ethyl acetate and part of deionized water are removed under reduced pressure, so that the solid content in the final emulsion is about 55%, and the emulsion is turned into mi...

Embodiment 6

[0042] Application of Lutein Dry Powder in Orange Juice Beverage

[0043] (1) Orange Juice Drink Recipe

[0044] Element

Amount added (g)

concentrated orange juice

20

White sugar

80

High Ester Pectin

0.5

1.5

Sodium iso-Vc

0.4

Lutein dry powder

0.2

water

add up to 1000

[0045] (2) Technological process: dissolve the ingredients, mix them evenly;

[0046] The amount of lutein added: 10mg / kg. The amount of lutein added during production can be appropriately increased or decreased according to nutritional fortification and coloring chromaticity requirements.

[0047] (3) Physical stability and chemical stability of orange juice beverage

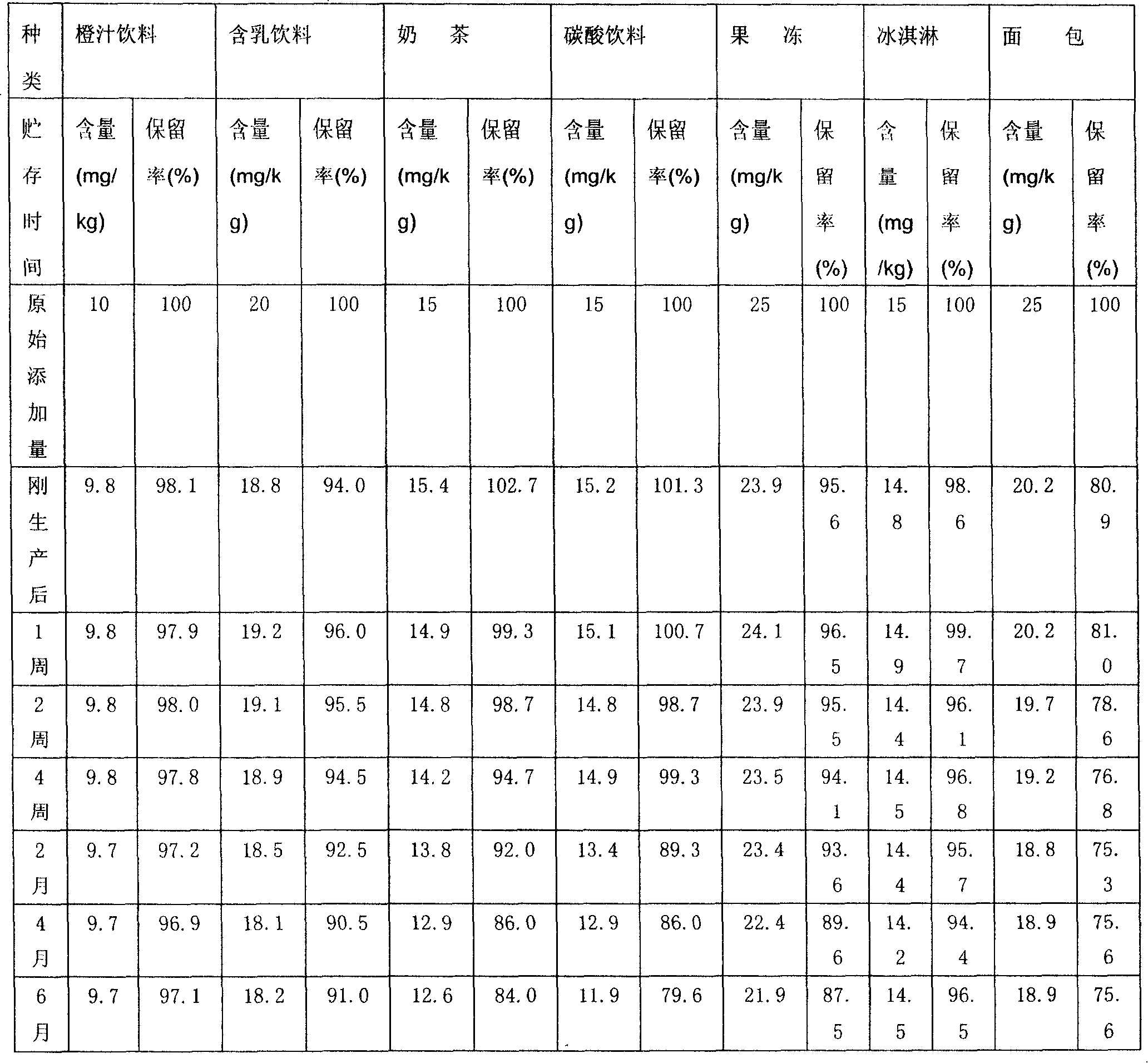

[0048] The physical stability and chemical stability of the orange juice beverage added with lutein are shown in Table 2 and Table 3, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com