Temporary plugging agent for pH-sensitive drilling fluid, and preparation method and using method thereof

A technology of drilling fluid and temporary plugging agent, applied in the field of temporary plugging agent, can solve the problems of poor temperature resistance, the temporary plugging agent does not have pH responsiveness, etc., achieves strong temperature resistance, restores reservoir permeability, and improves single well production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

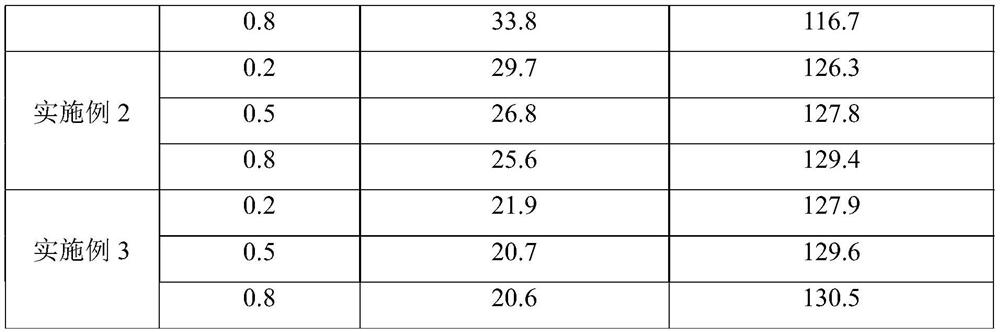

Examples

preparation example Construction

[0047] In the present invention, the preparation method of PEOx-DMMA modified nano silicon dioxide powder comprises the following steps: a) adding nano silicon dioxide particles into the reactor, slowly adding acetone, then adding a dispersant, stirring, standing and aging; b) add silane coupling agent and NaOH successively, heat up for the first time, increase the stirring speed, and make the silane coupling agent hydrolyze and condense with the silicon hydroxyl groups on the surface of nano-silica particles; c) add 2-methyl-2 -Oxazoline monomer, cool down, add initiator 1, make 2-methyl-2-oxazoline monomer ring-opening polymerization; d) make the system anoxic, add methacrylic acid N,N-dimethylaminoethyl ester, and initiator 2, reduce the stirring speed, and raise the temperature for the second time, so that N,N-dimethylaminoethyl methacrylate undergoes graft copolymerization; Pressure distillation and drying to obtain PEOx-DMMA modified nano silicon dioxide powder.

[0048...

Embodiment 1

[0083] Preparation of PEOx-DMMA modified nano silica:

[0084] a) Add 1000g of SP15 nano-silica particles into the high-pressure homogenizer, slowly add 2000mL of acetone, then add 30g of sodium dioctyl sulfosuccinate, stir at 10000rpm for 2h, and let stand for 2h;

[0085] b) Add 10g of silane coupling agent KH151 into the above reactor, then add 5g of NaOH, raise the temperature of the system to 80°C, increase the stirring speed to 20000rpm, and continue the reaction for 6h;

[0086] c) Add 30g of 2-methyl-2-oxazoline monomer (PEOx) into the above reactor, lower the system temperature to 50°C, add 3g of azobisisobutyronitrile, and react for 2h;

[0087]d) Pass high-purity nitrogen gas into the above reactor to remove oxygen for 3 hours, add 60g of N,N-dimethylaminoethyl methacrylate, add 6g of tert-butyl hydroperoxide, reduce the stirring speed to 5000rpm, and the temperature of the system rises Up to 70°C, continue to react for 8 hours;

[0088] e) After the reaction, was...

Embodiment 2

[0096] Preparation of PEOx-DMMA modified nano silica:

[0097] a) Add 1200g SP30T nano-silica particles into the high-pressure homogenizer, slowly add 2000mL acetone, then add 40g monoglyceride stearate, stir at 10000rpm for 2h, and let it stand for 2h;

[0098] b) Add 20g of silane coupling agent KH171 into the above reactor, then add 7g of NaOH, raise the temperature of the system to 90°C, increase the stirring speed to 20000rpm, and continue the reaction for 7h;

[0099] c) Add 40g of 2-methyl-2-oxazoline monomer (PEOx) into the above reactor, lower the system temperature to 55°C, add 4g of azobisisoheptanonitrile, and react for 2.5h;

[0100] d) Pass high-purity nitrogen gas into the above reactor to remove oxygen for 3 hours, add 70g of N,N-dimethylaminoethyl methacrylate, add 7g of tert-butyl peroxybenzoate, reduce the stirring speed to 5000rpm, and the system temperature Raise to 75°C and continue to react for 9 hours;

[0101] e) After the reaction, wash with acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Crack width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com