Shale inhibitor organosilicon polymer used for drilling fluid and preparation method of shale inhibitor organosilicon polymer

A technology of shale inhibitors and polymers, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of reducing the expansion coefficient of shale, reducing the rate of clay slurrying, etc., so as to reduce the expansion coefficient and improve the Rheological properties, moisture content suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

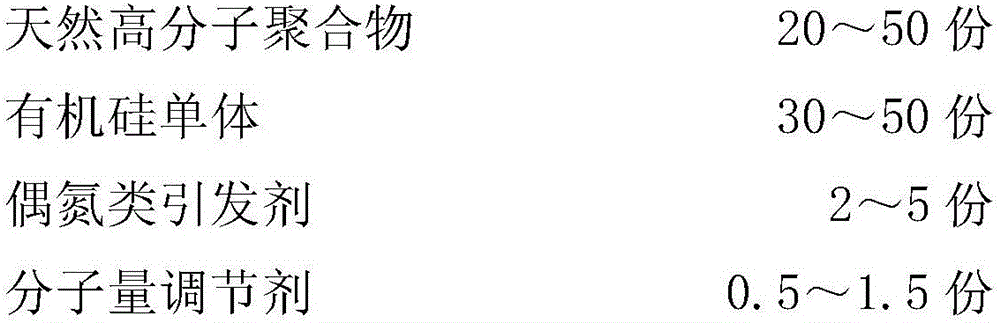

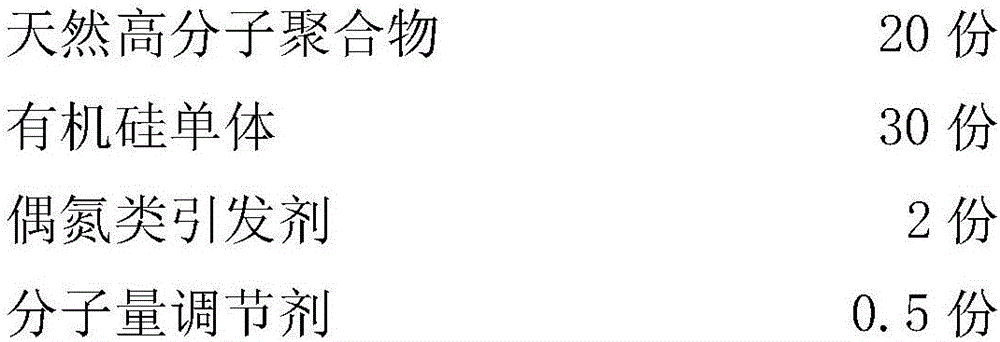

[0039] Embodiment 1: the shale inhibitor organosilicon polymer for drilling fluid of the present invention is to be made from the raw material of following weight ratio:

[0040]

[0041] The above-mentioned natural high molecular polymer is selected from lignin, the above-mentioned azo initiator is selected from azobisisoheptanonitrile, and the molecular weight regulator is selected from dodecyl mercaptan.

[0042] The preparation method of the shale inhibitor organosilicon polymer for drilling fluid includes the following process steps: ① firstly take the natural high molecular polymer according to the above weight ratio, add it into the reaction kettle, and add the natural high molecular weight polymer The molecular polymer undergoes a degradation reaction, which is hydrolyzed into a macromolecular compound at 80°C, and the reaction time is 2 hours to obtain an intermediate product; ②Then add the above-mentioned organosilicon monomer, azo Initiator and molecular weight r...

Embodiment 2

[0043] Embodiment 2: the shale inhibitor organosilicon polymer for drilling fluid of the present invention is to be made from the raw material of following weight ratio:

[0044]

[0045] The above-mentioned natural high molecular polymer is selected from chitosan, the above-mentioned azo initiator is selected from azobisisoheptanonitrile, and the molecular weight regulator is selected from sodium methacrylic sulfonate.

[0046] The preparation method of the shale inhibitor organosilicon polymer for drilling fluid includes the following process steps: ① firstly take the natural high molecular polymer according to the above weight ratio, add it into the reaction kettle, and add the natural high molecular weight polymer Molecular polymer undergoes a degradation reaction to hydrolyze it into a macromolecular compound at 60°C. The reaction time is 2 hours to obtain an intermediate product; ②Then add the above-mentioned organosilicon monomer, azo Initiator and molecular weight r...

Embodiment 3

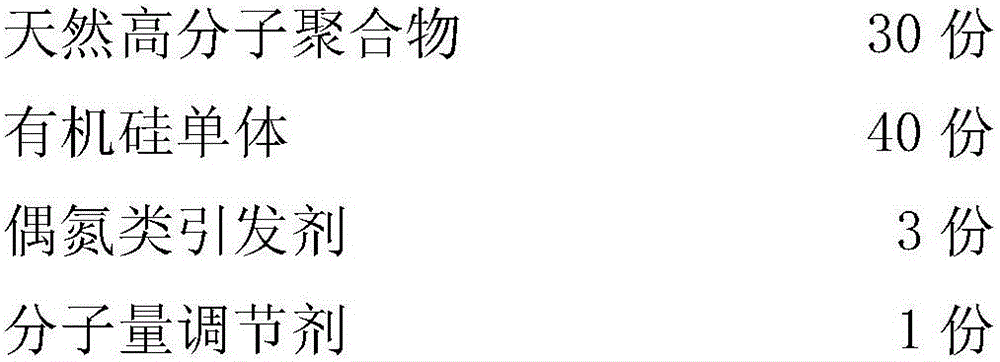

[0047] Embodiment 3: the shale inhibitor organosilicon polymer for drilling fluid of the present invention is made from the raw materials of following weight ratio:

[0048]

[0049] The above-mentioned natural high molecular polymer is selected from cellulose, the above-mentioned azo initiator is selected from azobisisovaleronitrile, and the molecular weight regulator is selected from mercaptopropionic acid.

[0050] The preparation method of the shale inhibitor organosilicon polymer for drilling fluid includes the following process steps: ① firstly take the natural high molecular polymer according to the above weight ratio, add it into the reaction kettle, and add the natural high molecular weight polymer Molecular polymer undergoes a degradation reaction to hydrolyze it into a macromolecular compound at 70°C. The reaction time is 2 hours to obtain an intermediate product; ②Then add the above-mentioned organosilicon monomer, azo Initiator and molecular weight regulator, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com