High-temperature ceramic adhesive and preparation method thereof

A technology of high-temperature adhesives and ceramics, applied in the direction of non-polymer adhesive additives, adhesives, inorganic adhesives, etc., can solve the problem of not meeting the temperature requirements of aerospace systems, and the limitations of bonding strength and temperature resistance , can not well meet the use requirements and other problems, to achieve the effect of convenient operation, short curing time and strong temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

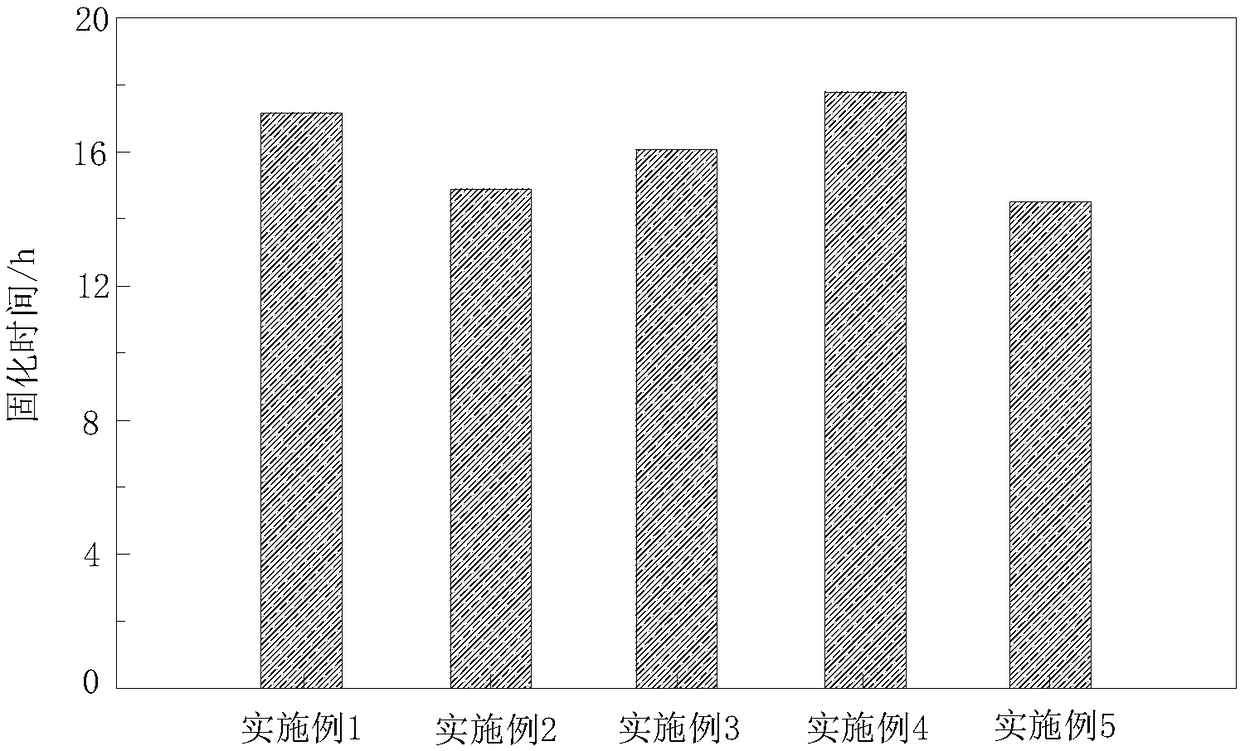

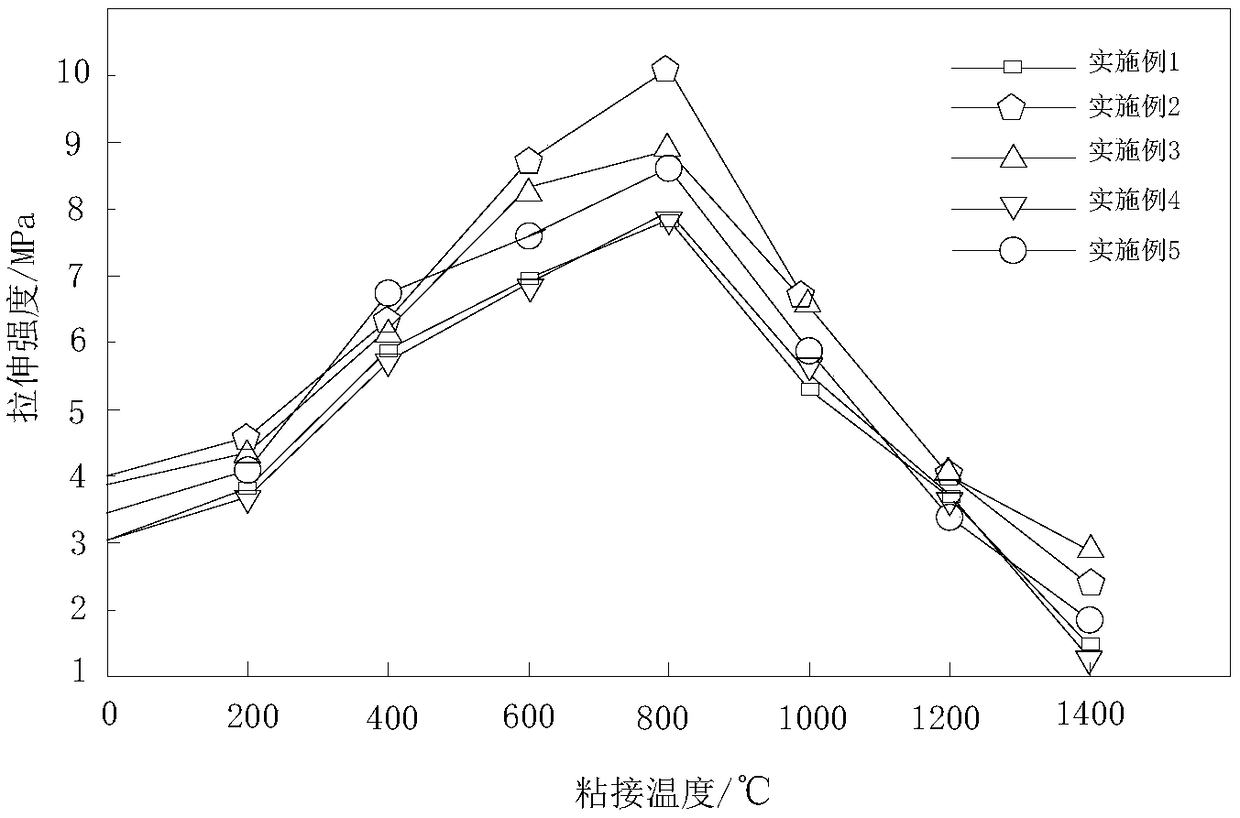

Examples

Embodiment 1

[0019] Example 1. A ceramic high-temperature adhesive, made from the following raw materials and steps:

[0020] Step 1. Dilute phosphoric acid to a mass fraction of 65%, add 65wt% phosphoric acid into a beaker and heat it in a water bath to 80-85°C, and add a certain amount of hydroxide in a molar ratio of 1:1 under the condition of mechanical stirring Aluminum, and continue to heat and stir, the obtained white paste viscous liquid is aluminum phosphate adhesive.

[0021] Step 2, get the aluminum phosphate adhesive that makes in 10g step 1, according to the mixture of nano-silica powder 0.5g, nano-titanium dioxide powder 0.4g, nano-zirconia powder 0.3g and nano-silicon nitride powder 0.2g, Prepared as an adhesive.

Embodiment 2-5

[0022] Examples 2-5. A ceramic high-temperature adhesive, made according to the following raw materials:

[0023] Adhesive composition table in embodiment 1-5

[0024]

[0025] The preparation steps of Examples 2-5 are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com