Whey protein antihypertensive peptide prepared by utilizing continuous enzyme membrane reactor and special device thereof

An enzyme membrane reactor and whey protein technology, applied in the field of whey protein blood pressure-lowering peptide and its special device, can solve the problems of unable to realize simultaneous proteolysis and separation of active peptide, unable to recycle, difficult to continuous production, etc. , to achieve the effect of eliminating the inhibition of the product on the enzyme, saving the production cost and having strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, preparation whey protein antihypertensive peptide

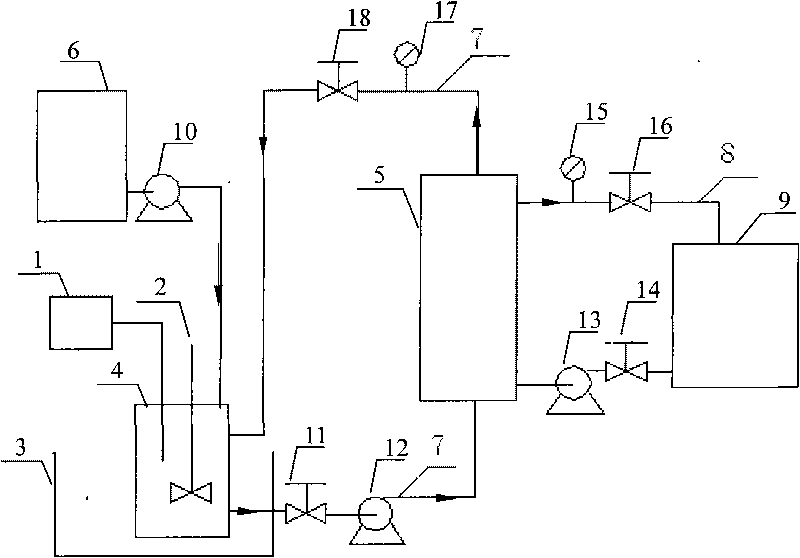

[0032] Prepare a concentrated whey protein solution with a mass concentration of 2%, and after hydration (hydration conditions: adjust the pH of the WPC solution to 7.5, then hydrate and continuously stir for 20 minutes at 85°C) to the continuous enzyme membrane reactor Add 2L of WPC solution to the reaction tank 4, control the temperature of the reaction tank to 40°C, and then add 80kU alkaline protease (purchased from Beijing Fangshan Enzyme General Factory) to the reaction tank 4 according to the ratio of 2000U protease / g whey protein Carry out enzymolysis reaction; Open valve 11,18, utilize peristaltic pump 12 to regulate circulation flow rate to be 12.5L / h, close valve 14 now, utilize valve 18 to regulate transmembrane pressure to be 0.02MPa (the pressure that pressure gauge 17 shows), The enzymatic hydrolysis reaction solution enters the ultrafiltration membrane module 3, the ultrafiltration membran...

Embodiment 2

[0038] Embodiment 2, preparation whey protein antihypertensive peptide

[0039] Select a concentrated whey protein solution with a mass concentration of 5%, after hydration, take 2L and add it to the reaction tank of the continuous enzyme membrane reactor, control the temperature at 50°C, and add 200kU of alkali according to the ratio of 2000U protease / g whey protein protease (purchased from Beijing Fangshan Enzyme General Factory); the circulating flow rate is 34.2L / h, the transmembrane pressure is adjusted to be 0.08MPa, the molecular weight cut-off of the ultrafiltration membrane is 10000Da, and the ultrafiltration process is continuously fed (the feeding concentration is 2.5 %). After 10 hours of continuous enzymatic hydrolysis, the change rate of the membrane flux was -4.58%~+3.78%, which was relatively stable. The protein recovery rate was 81.43%, and the ACE inhibition rate of the obtained whey protein blood pressure-lowering peptide was 83.18%. The cleaning method ad...

Embodiment 3

[0040] Embodiment 3, preparation whey protein antihypertensive peptide

[0041] Select the whey protein isolate solution with a mass concentration of 8%, get 2L and add it to the reaction tank of the continuous enzyme membrane reactor after hydration, add 320kU alkaline protease (purchased in Beijing City Fangshan Enzyme General Factory); Circulation velocity is at 44.2L / h, and regulation transmembrane pressure is 0.08MPa, and ultrafiltration membrane molecular weight cut-off is 10000Da, and ultrafiltration process is constantly fed (feed concentration is 3%). After continuous enzymatic hydrolysis for 10 hours, the change rate of the membrane flux was -11.82~+11.91%, which was relatively stable. The protein recovery rate was 85.21%, and the ACE inhibition rate of the obtained whey protein-derived hypotensive peptide was 81.08%. The cleaning method adopts the cleaning method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com