Method for measuring malic acid-lactic acid fermentation quality of wine

A technology of lactic acid fermentation and determination method, applied in the field of analysis and determination of wine, can solve the problems of inaccurate quantification, time-consuming, heavy interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

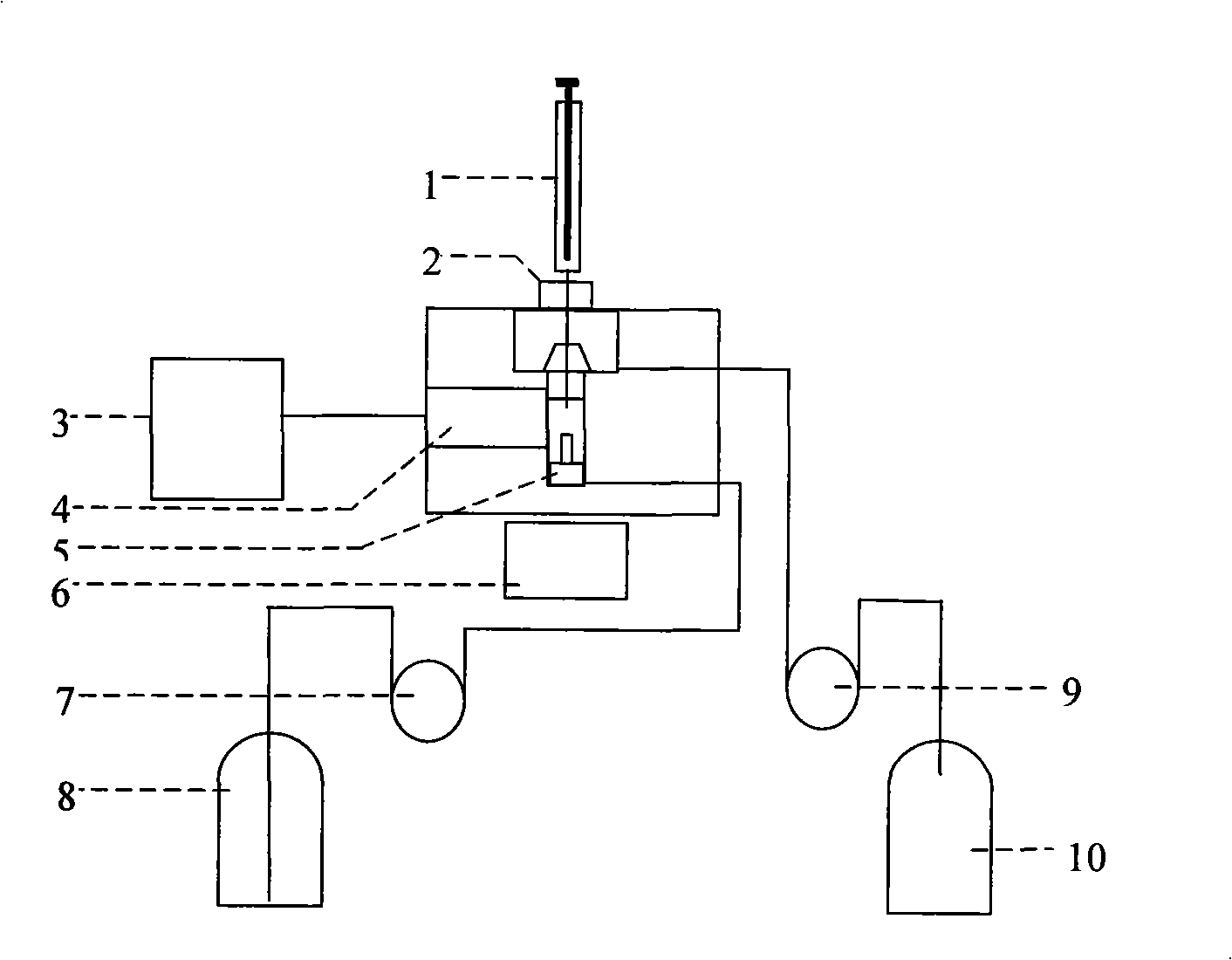

[0032] 1 Instruments and reagents

[0033] 1.1 Reagent L-lactate oxidase (EC 1.1.1.27): American Sigma Company; L-lactic acid: American Sigma Company; glutaraldehyde: Shanghai Chemical Reagent Purchasing and Supply Station imported packaging; nuclear microporous membrane: American Nucleopore Company (φ0 .2 μm); platinum and silver: Jinan Branch of the People's Bank of China (purity 99.999%); other reagents are analytically pure, wine fermentation liquid: Yantai Nanshan Wine Co., Ltd.

[0034] 1.2 Instruments SBA-40 Lactic Acid Biosensing Analyzer (Shandong Academy of Sciences Institute of Biology).

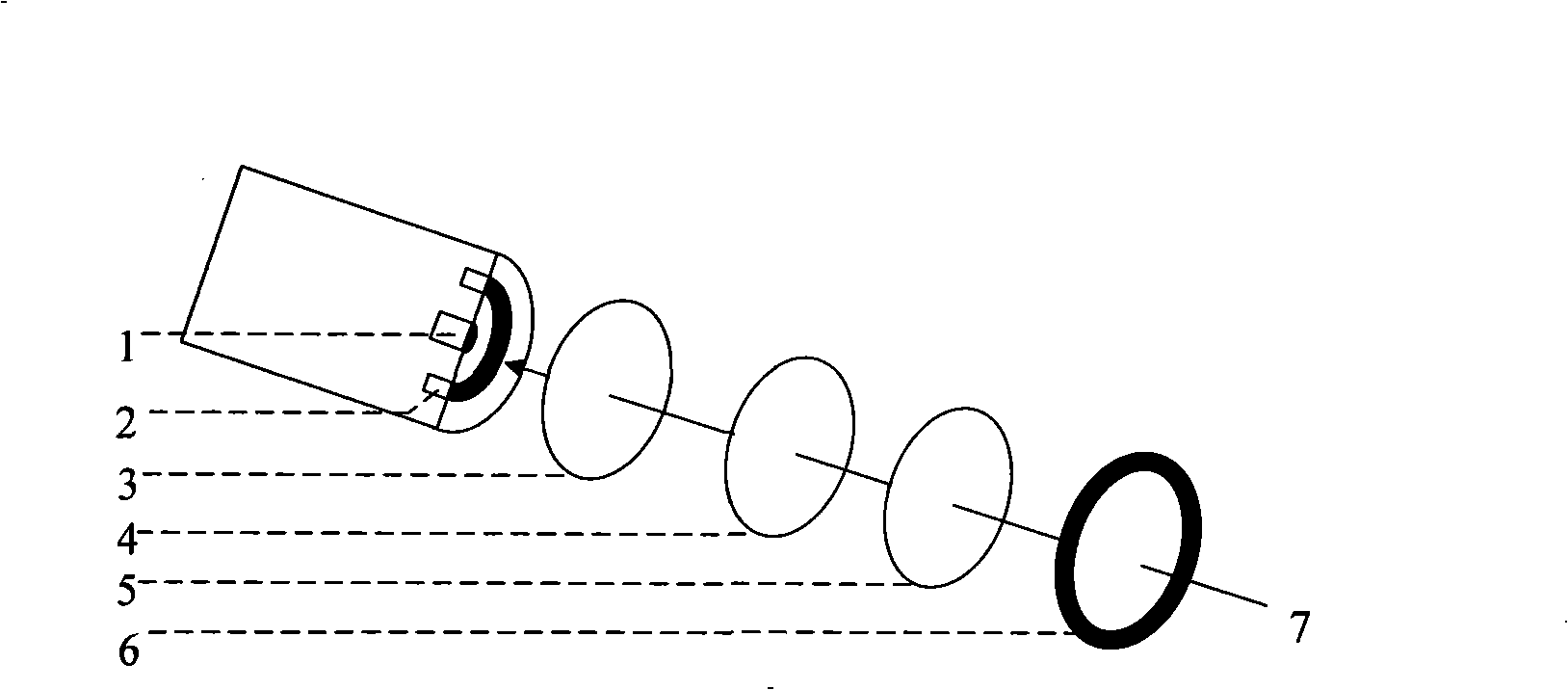

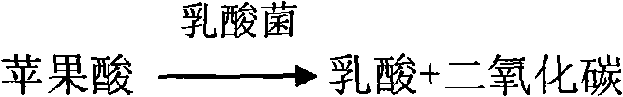

[0035] 2 Determination principle: immobilized L-lactate oxidase combined with H 2 o 2 Electrode determination of L-lactic acid principle

[0036]

[0037]

[0038]

[0039] 3 Preparation of L-lactic acid reference substance solution: Accurately weigh 50 mg of L-lactic acid reference substance, put it in a 100ml volumetric flask, add distilled water to dissolve, and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com