Preparation method of organic/inorganic composite intermediate/high-temperature proton conductive membrane

A proton-conducting membrane and inorganic composite technology, which is applied to fuel cell components, solid electrolyte fuel cells, circuits, etc., can solve problems such as poor ionic conductivity and poor mechanical strength, and achieve improved proton conductivity and adsorption stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

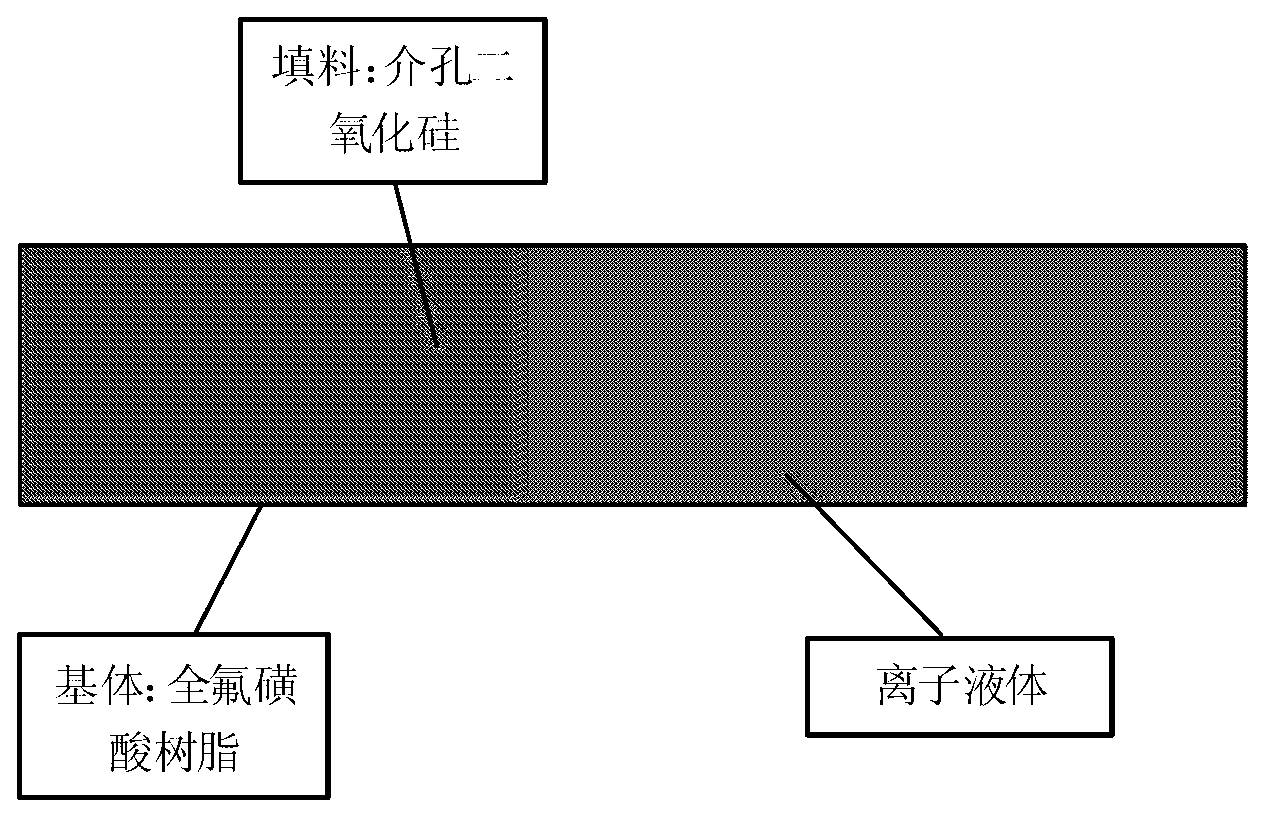

Method used

Image

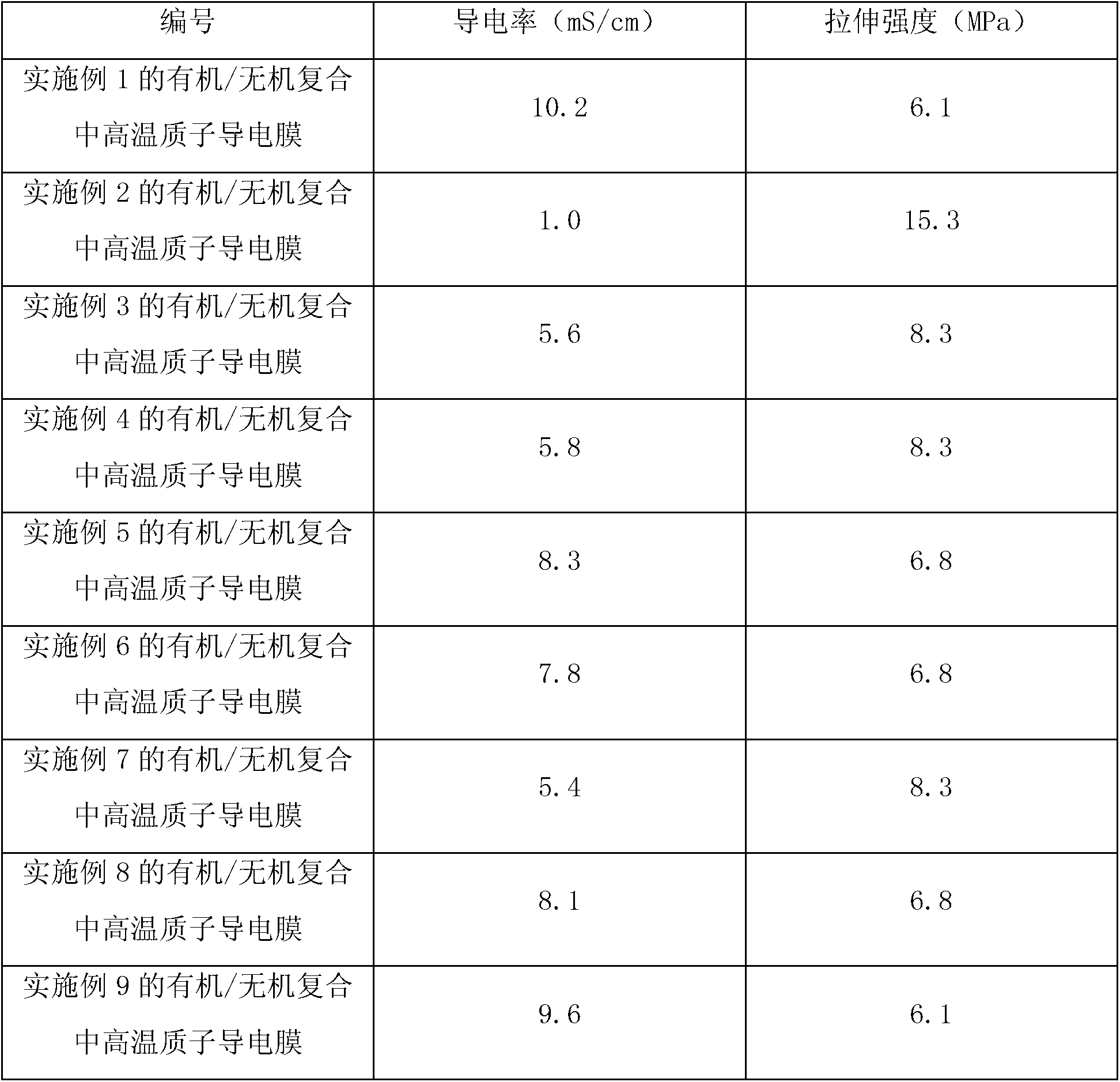

Examples

Embodiment 1

[0027] A method for preparing an organic / inorganic medium-high temperature proton conductive membrane, comprising the following steps:

[0028] (1) Mix perfluorosulfonic acid resin, mesoporous silica particles, and dimethylformamide in a mass ratio of 100:70:100 to form a suspension;

[0029] (2) Cast the above suspension on a smooth glass plate and solidify to form a film;

[0030] (3) Soak the above membrane in [dema][TfO] ionic liquid for 8 hours, so that the ionic liquid is absorbed into the membrane, wherein the mass of the ionic liquid absorbed into the membrane is 80% of the mass of the perfluorosulfonic acid resin ;

[0031] (4) The membrane after absorbing the ionic liquid is taken out from the ionic liquid, and the ionic liquid on the surface of the membrane is removed with filter paper to obtain the organic / inorganic composite medium-high temperature proton conductive membrane of the present invention.

[0032] Among them, the equivalent weight of perfluorosulfoni...

Embodiment 2

[0034] A method for preparing an organic / inorganic medium-high temperature proton conductive membrane, comprising the following steps:

[0035] (1) Mix perfluorosulfonic acid resin, mesoporous silica particles, and dimethylacetamide at a mass ratio of 100:5:2000 to form a suspension;

[0036] (2) Cast the above suspension on a smooth glass substrate and solidify to form a film;

[0037] (3) Soak the above membrane in [dema][TfO] ionic liquid for 8 hours, so that the ionic liquid is absorbed into the membrane, and the mass of the ionic liquid absorbed into the membrane is 10% of the mass of the perfluorosulfonic acid resin ;

[0038] (4) The membrane after absorbing the ionic liquid is taken out from the ionic liquid, and the ionic liquid on the surface of the membrane is removed with filter paper to obtain the organic / inorganic composite medium-high temperature proton conductive membrane of the present invention.

[0039] Among them, the equivalent weight of perfluorosulfoni...

Embodiment 3

[0041] A method for preparing an organic / inorganic medium-high temperature proton conductive membrane, comprising the following steps:

[0042] (1) Mix perfluorosulfonic acid resin, mesoporous silica particles, and dimethyl sulfoxide at a mass ratio of 100:40:1000 to form a suspension;

[0043] (2) Cast the above suspension on a smooth glass substrate and solidify to form a film;

[0044] (3) Soak the above membrane in [dema][TfO] ionic liquid for 8 hours, so that the ionic liquid is absorbed into the membrane, and the mass of the ionic liquid absorbed into the membrane is 40% of the mass of the perfluorosulfonic acid resin ;

[0045] (4) The membrane after absorbing the ionic liquid is taken out from the ionic liquid, and the ionic liquid on the surface of the membrane is removed with filter paper to obtain the organic / inorganic composite medium-high temperature proton conductive membrane of the present invention.

[0046] Among them, the equivalent weight of perfluorosulfoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com