Method for preparing peptide of decrease blood pressure in laver by using enzyme-membrane coupling technique and application thereof

A technology of blood pressure-lowering peptide and seaweed, which is applied in the field of development and utilization of marine plant protein, can solve problems such as large consumption of enzymes, inability to apply industrialized production, and complexity, so as to improve product quality, reduce the operation of inactivating enzymes, and realize recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

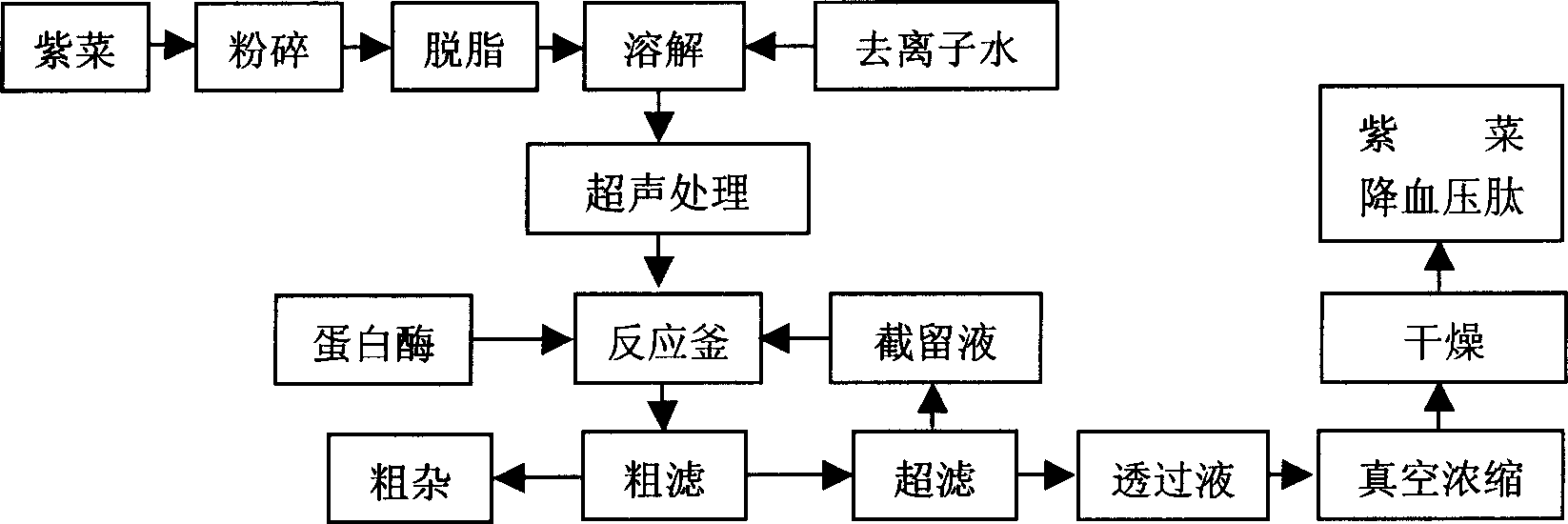

Method used

Image

Examples

Embodiment 1

[0021] Weigh 10kg of dried laver, crush it, and under the conditions of 30MPa and 35°C, use supercritical CO 2 Extraction technology removes the oil therein, and the EPA+DHA in the obtained laver oil reaches 50%, which can be used to develop auxiliary blood fat-lowering functional food. Then, add 10 times the weight of deionized water to the degreased laver powder, stir and dissolve, so that the solution concentration is 10%, and circulate the ultrasonic action in the ultrasonic treatment equipment for 20 minutes.

[0022] Measure 10L of ultrasonically treated laver solution, add alkaline protease according to the ratio of 25AU protease / kg solution, and carry out enzymatic hydrolysis under the conditions of pH 9 and temperature 60°C. The enzymatic hydrolysis reaction solution is first filtered with a cloth bag, and then sent to the ultrafiltration equipment. The molecular weight cut-off of the ultrafiltration membrane is 5kDa, and the ultrafiltration pressure is 0.5mPa. The ...

Embodiment 2

[0025] Weigh 5 kg of degreased laver powder, add 20 times the weight of deionized water, stir and dissolve, so that the solution concentration is 5%, and circulate the ultrasonic action in the ultrasonic treatment equipment for 35 minutes.

[0026] Measure 10L of ultrasonically treated seaweed solution, add neutral protease at a concentration of 15AU protease / kg, and perform enzymatic hydrolysis at pH 6.8 and temperature 45°C. The enzymatic hydrolysis reaction solution is first filtered with a cloth bag, and then sent to the ultrafiltration equipment. The molecular weight cut-off of the ultrafiltration membrane is 10kDa, and the ultrafiltration pressure is 0.3mPa. The ultrafiltration membrane retentate is returned to the enzymatic hydrolysis reactor. The permeate of the ultrafiltration membrane is the obtained laver hypotensive peptide solution. According to the content of polypeptide and moisture in the permeate, set the ratio of replenishing laver solution to the enzymolys...

Embodiment 3

[0029] Weigh 5 kg of degreased laver powder, add 15 times the weight of deionized water, stir and dissolve, so that the solution concentration is 6.67%, and circulate the ultrasonic action in the ultrasonic treatment equipment for 25 minutes.

[0030] Measure 10L of ultrasonically treated laver solution, add compound protease at a concentration of 21AU / kg, and perform enzymatic hydrolysis under the conditions of pH 5.2 and temperature 30°C. The enzymatic hydrolysis reaction solution is first filtered with a cloth bag, and then sent to the ultrafiltration equipment. The molecular weight cut-off of the ultrafiltration membrane is 10kDa, and the ultrafiltration pressure is 0.5mPa. The ultrafiltration membrane retentate is returned to the enzymatic hydrolysis reactor. The permeate of the ultrafiltration membrane is the obtained laver hypotensive peptide solution. According to the content of polypeptide and moisture in the permeate, set the ratio of replenishing laver solution to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com