Method for improving yield of soybean peptide with low molecular weight

A low-molecular-weight, soybean peptide technology, applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of large molecular weight of soybean peptide products, insufficient clarity and transparency of the solution, dark solution color, etc. The effect of high peptide content and low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

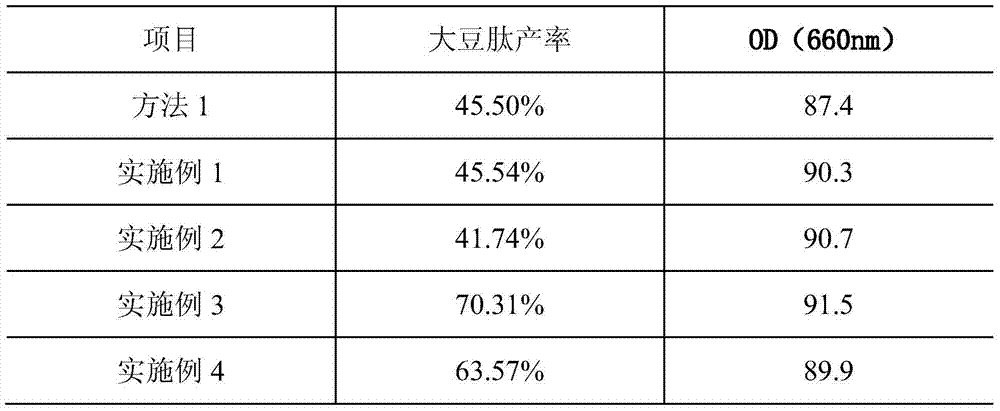

Examples

Embodiment 1

[0021] A kind of method that the present embodiment provides to improve the yield of low molecular weight soybean peptide comprises the following steps:

[0022] (1) Weigh soybean protein isolate, add water, and after the soybean protein isolate is fully dissolved, adjust the pH of the soybean protein isolate solution to 6;

[0023] (2) After sterilizing the soybean protein isolate solution obtained in step (1), add a compound protease for enzymolysis to obtain an enzymolysis solution. The sugar content of the liquid is 5BX, and the pH value is 6;

[0024] (3) After treating the enzymolysis solution obtained in step (2) with a microfiltration membrane, add water to wash the filtrate, and collect the filtered soybean peptide mixture; the sugar content of the obtained filtrate is 4BX, and the water in the cleaning process The weight ratio with the filtrate is 1:1;

[0025] (4) The soybean peptide mixture obtained in step (3) is subjected to nanofiltration operation, and the co...

Embodiment 2

[0028] A kind of method that the present embodiment provides to improve the yield of low molecular weight soybean peptide comprises the following steps:

[0029] (1) Weigh soybean protein isolate, add water, and after the soybean protein isolate is fully dissolved, adjust the pH of the soybean protein isolate solution to 8;

[0030] (2) After sterilizing the soybean protein isolate solution obtained in step (1), add a compound protease for enzymolysis to obtain an enzymolysis solution. The sugar content of the liquid is 10BX, and the pH value is 8;

[0031] (3) After treating the enzymolysis solution obtained in step (2) with a microfiltration membrane, add water to wash the filtrate, and collect the filtered soybean peptide mixture; the sugar content of the obtained filtrate is 10BX, and the water in the cleaning process The weight ratio with the filtrate is 1:5;

[0032] (4) The soybean peptide mixture obtained in step (3) is subjected to nanofiltration operation, and the ...

Embodiment 3

[0035] A kind of method that the present embodiment provides to improve the yield of low molecular weight soybean peptide comprises the following steps:

[0036] (1) Weigh soybean protein isolate, add water, and after the soybean protein isolate is fully dissolved, adjust the pH of the soybean protein isolate solution to 8;

[0037] (2) After sterilizing the soybean protein isolate solution obtained in step (1), add a compound protease for enzymolysis to obtain an enzymolysis solution. The sugar content of the liquid is 18BX, and the pH value is 8;

[0038] (3) After treating the enzymolysis solution obtained in step (2) with a microfiltration membrane, add water to wash the filtrate, and collect the filtered soybean peptide mixture; the sugar content of the obtained filtrate is 15BX, and the water in the cleaning process The weight ratio with the filtrate is 1:15;

[0039] (4) Perform nanofiltration operation on the soybean peptide mixture obtained in step (3), and collect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brix | aaaaa | aaaaa |

| Brix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com