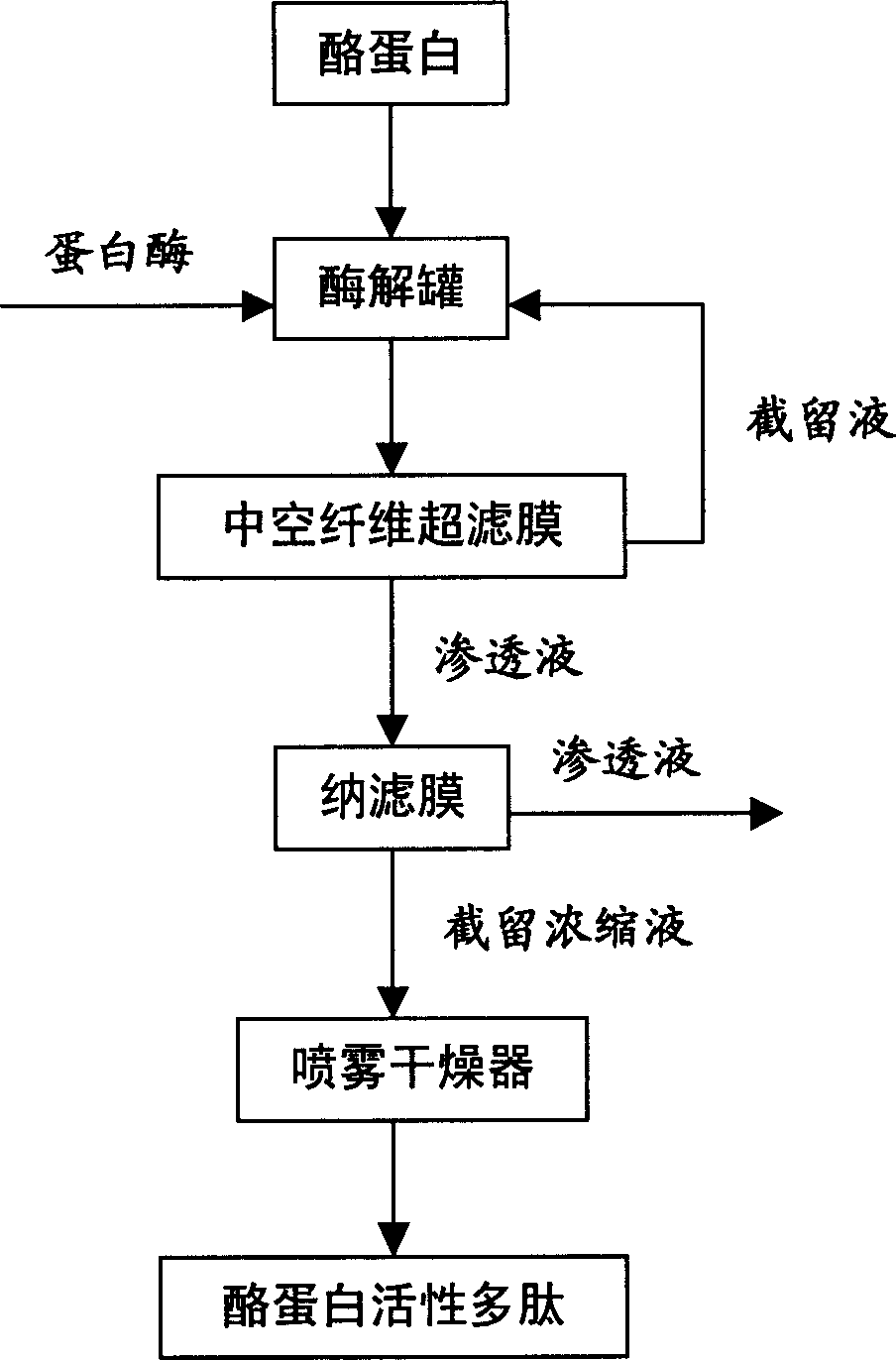

Process of continuous production of casein bioactive peptide by enzymolysis and filtering membrane concentration

A technology for biologically active polypeptides and casein, which is applied in the field of enzymatic hydrolysis to prepare active polypeptides, which can solve the problems that the enzymatic hydrolysis products cannot be separated from the reaction system in time, the conversion rate of the enzymatic hydrolysis reaction is low, the yield of the target polypeptide is low, and the product quality is unstable and other problems, to achieve the effect of prolonging the effective reaction time, tending to uniform composition and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Weigh 800g of casein, add 20L of water and place it in a liquid storage tank, heat slightly and stir well, slowly add 16mL of 1g / mL NaOH solution to prepare a casein substrate solution with a pH of 8.5 and a concentration of 4%. Put it into the hydrolysis tank, adjust the stirring speed to 80rmp, start the constant temperature water bath, and after the temperature is constant at 45°C, open the ultrafiltration circulation device, the average molecular weight cut-off of the ultrafiltration membrane is 10000, and the substrate solution is circulated at a flow rate of 30L / h. Stable circulation at normal pressure for 15 minutes, add 20 grams of alkaline protease to the hydrolysis tank, start the continuous enzymatic hydrolysis reaction and record the time, after 10 minutes, adjust the operating pressure of the ultrafiltration membrane to 0.05MPa, casein, protease and macromolecular polypeptides and other macromolecular substances It is intercepted by the ultrafiltration membr...

Embodiment 2

[0016] Adopting the ultrafiltration membrane that the average molecular weight cut off is 6000 and the nanofiltration membrane that the average molecular weight cut off is 2000 and 20L enzymolysis tank form continuous reaction separation system, add 20g trypsin to 20L mass concentration and be 2% casein substrate solution, During the reaction process, keep the system temperature at 40°C and pH=8.0 constant, continuously add 1% casein substrate solution to keep the reaction volume and effective substrate concentration constant, add 4g of trypsin every 4 hours to maintain the constant enzyme activity of the system, Other enzymatic hydrolysis reactions and membrane separation operation steps and process parameters are the same as in Example 1, and the active polypeptide products mainly composed of casein phosphopeptides are obtained. The products are detected and analyzed by HPSEC, and the molecular weights are mainly concentrated in the corresponding peaks of 3000-5000. Nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com