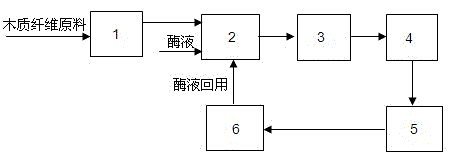

Method for producing ethanol by continuous enzymolysis and fermentation of lignocellulose

A technology for lignocellulose and ethanol production, applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve certain problems in heat transfer efficiency and heat transfer uniformity, low enzymatic hydrolysis efficiency, ethanol production Low efficiency and other problems, to achieve high efficiency and low cost operation, increase ethanol yield, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

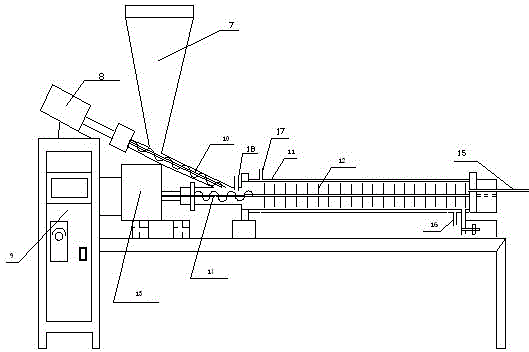

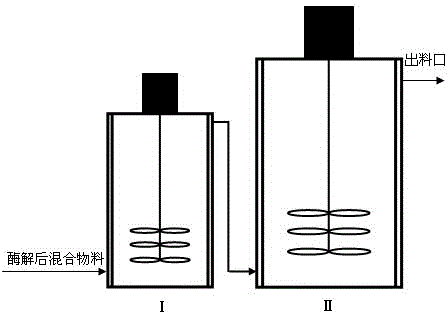

[0032] The volume of the horizontal enzymolysis reactor is 2.2L, the aspect ratio is 11:1, and the length of the stirring bar is 0.9 times the radius of the reactor. Turn on the screw feeding unit, PCS gradually fills the horizontal enzymolysis reactor with the passage of time, control the screw feeding speed to 0.16rpm, and the peristaltic pump flow acceleration to 1.6rpm, so that the added material and the required enzyme liquid phase Add the horizontal enzymolysis reactor at the same time, and fill the horizontal enzymolysis reactor within 20 hours. Using 20wt% dry matter concentration, the enzyme dosage is 7IU / g cellulose dry base system, that is, the amount of PCS added to the screw every 20h is 978g. The enzyme solution includes 110 g of 1M citrate buffer, 1104 g of water and 8 g of cellulase, with a pH value of 5.0. The enzymatic hydrolysis temperature is 48°C, and the residence time is 20h.

[0033] As the enzymolysis progresses, the pressure of the screw pushes the ...

Embodiment 2

[0036] Using 30wt% dry matter concentration, the enzyme dosage is 7IU / g cellulose dry base system for continuous enzymolysis and fermentation.

[0037] Open the screw feed unit, the volume of the horizontal enzymolysis reactor is 2.2L, PCS gradually fills the horizontal enzymolysis reactor with the passage of time, control the screw feed rate to 0.1rpm, and the peristaltic pump flow acceleration to 1.1rpm, The added material and the required enzyme solution are added to the horizontal enzymolysis reactor at equal time, and the horizontal enzymolysis reactor is filled within 30 hours, that is, the amount of PCS added by the screw every 30 hours is 1467g. The enzyme solution includes 110 g of 1M citrate buffer, 611 g of water and 12 g of cellulase, with a pH value of 5.0. The enzymatic hydrolysis temperature is 52°C, and the residence time is 30h.

[0038] As the enzymolysis progresses, the pressure of the screw pushes the partially enzymolyzed PCS at the end of the horizontal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com