Preparation method of fixed enzyme membrane

A technique of immobilizing enzymes and polypropylene membranes, which is applied in the direction of fixing on/in organic carriers, can solve the problems of low catalytic activity and low enzyme protein loading capacity of immobilized enzyme membranes, and achieve good catalytic activity, Increased protease loading and the effect of increasing the enzyme protein loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

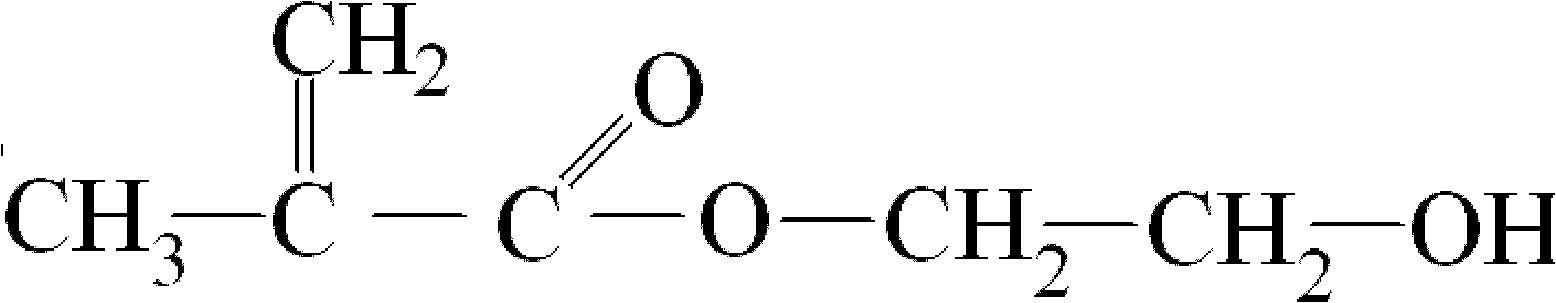

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment 1: The preparation method of the immobilized enzyme membrane of this embodiment is carried out according to the following steps: 1. The polypropylene membrane is soaked in acetone for 22-26 hours, then dried at 25-35° C. for 22-26 hours, and then put into a concentration of In the acetone solution of 0.2mol / L benzophenone, under the protection of nitrogen, irradiate with ultraviolet light for 14-16min, and the intensity of ultraviolet light irradiation is 90-110μW / cm 2 , the irradiation distance is 11-13cm, and then the film is dried naturally and immersed in an ethanol solution of methyl methacrylate with a mass concentration of 10%-30%, shaken in a water bath at 28-32°C for 22-26h, and then at 28 Vacuum drying under the condition of ~32 ° C for 22 ~ 26h can obtain the methyl methacrylate grafted film, wherein the solvent of the ethanol solution of methyl methacrylate is ethanol with a mass concentration of 90% ~ 99%; two, methacrylic acid The methy...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the polypropylene film is soaked in acetone for 24 hours. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment is different from Embodiments 1 to 2 in that: in step 1, dry at 30° C. for 24 hours. Other steps and parameters are the same as those in Embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com