Grease catalysis separation biphasic enzyme-film bioreactor and its preparation and application

A membrane bioreactor, oil and ester technology, applied in the direction of enzyme production/bioreactor, single-component synthetic polymer rayon, fiber chemical characteristics, etc., can solve the problem of weak binding force between enzyme protein and carrier, enzyme shedding, difficult Catalyze macromolecular substrate reactions and other issues to achieve the effects of improving enzyme utilization, high specific surface area and porosity, and improving biological activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

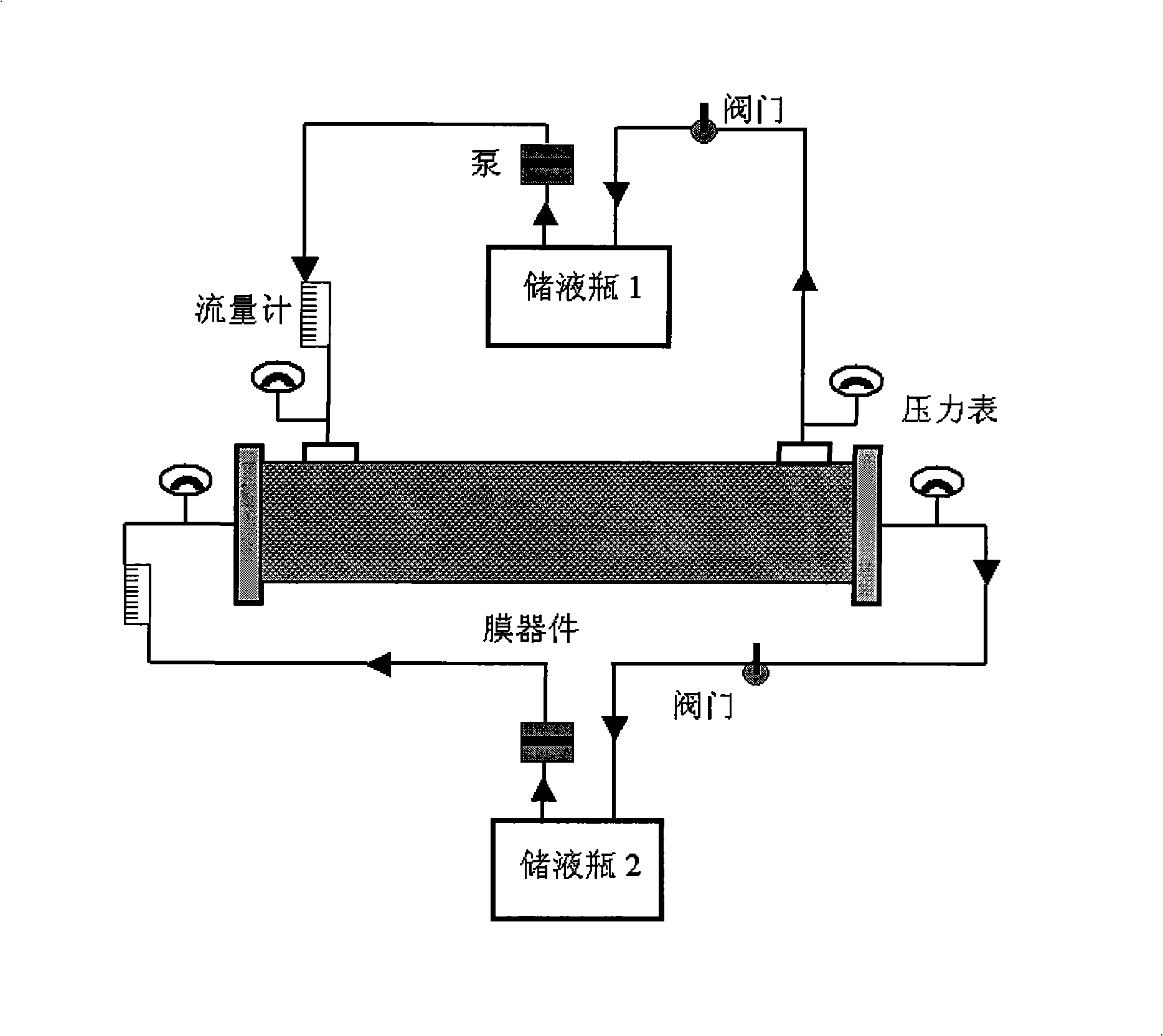

[0026] Dissolve amino-containing polyphosphazene with a molecular weight of 500,000 in chloroform to form a spinning solution with a concentration of 12wt.%. The spinning voltage is 5kV, the flow rate of the spinneret solution is 2.0mL / h, and the receiving distance is 10cm. Next, electrospinning is carried out to make a superfine fiber composite membrane, and polyester non-woven fabric is used as a supporting material, which is filled in an inner and outer double cylindrical membrane tool to form a membrane device. The prepared polyphosphazene microfiber membrane device is connected in series such as figure 1 In the device shown, a membrane reactor is formed, and glutaraldehyde is first injected into the membrane reactor by means of cross-flow filtration, and circulated in the membrane reactor device at 20°C for 3 hours, and then the fat with a concentration of 5g / L The enzyme solution was circulated in the membrane reactor device at 20° C. for 3 hours, so as to realize the ac...

Embodiment 2

[0028] Dissolve amino-containing polyphosphazene with a molecular weight of 600,000 in chloroform to prepare a spinning solution with a concentration of 1wt.%. The spinning voltage is 22kV, the flow rate of the spinneret solution is 0.1mL / h, and the receiving distance is 10cm. Next, electrospinning is carried out to make a superfine fiber composite membrane, and polyester non-woven fabric is used as a supporting material, which is filled in an inner and outer double cylindrical membrane tool to form a membrane device. The prepared polyphosphazene microfiber membrane device is connected in series such as figure 1 In the device shown, a membrane reactor is formed, and glutaraldehyde is first injected into the membrane reactor by means of cross-flow filtration, and circulated in the membrane reactor device at 20°C for 3 hours, and then the fat with a concentration of 5g / L The enzyme solution was circulated in the membrane reactor device at 20° C. for 3 hours, so as to realize the...

Embodiment 3

[0030] The amino-containing polyphosphazene with a molecular weight of 700,000 was dissolved in chloroform to form a spinning solution with a concentration of 9wt.%. The spinning voltage was 30kV, the flow rate of the spinneret solution was 0.5mL / h, and the receiving distance was 5cm. Next, electrospinning is carried out to make a superfine fiber composite membrane, and polyester non-woven fabric is used as a supporting material, which is filled in an inner and outer double cylindrical membrane tool to form a membrane device. The prepared polyphosphazene microfiber membrane device is connected in series such as figure 1 In the device shown, a membrane reactor is formed, and glutaraldehyde is first injected into the membrane reactor by means of cross-flow filtration, and circulated in the membrane reactor device at 25°C for 2.5 hours, and then the fat with a concentration of 5g / L The enzyme solution was circulated in the membrane reactor device for 2.5 hours at 25° C., so as to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com