Preparation method of corn oligopeptide

A technology of corn oligopeptide and corn protein, which is applied in the biological field, can solve the problems such as the molecular weight distribution data of corn peptide crude protein content, etc., and achieve the effects of molecular weight concentration, purity improvement, and dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

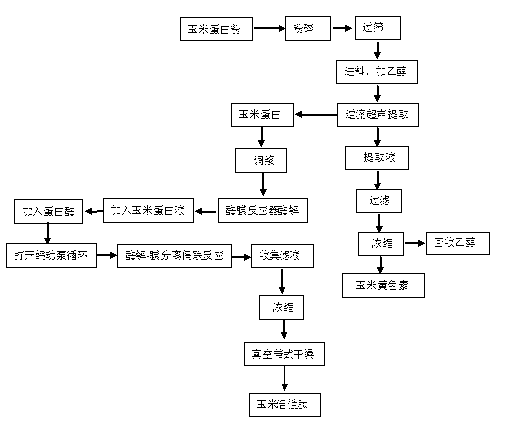

Method used

Image

Examples

Embodiment 1

[0022] (1) Pretreatment of corn gluten meal

[0023] ①Crush corn gluten powder, pass through a 30-mesh sieve, and input it into the extraction tube from the feed port, and at the same time, input ethanol with a pH of 7, a concentration of 70%, and a temperature of 30°C into the extraction tube from the liquid inlet of the extractor. The liquid ratio is 1:4.

[0024] ②Corn gluten powder and ethanol were subjected to countercurrent ultrasonic extraction in the extraction tube of a continuous countercurrent ultrasonic extraction machine for 30 minutes. The conditions of ultrasonic extraction were: temperature 30°C, ultrasonic frequency 40kHz.

[0025] ③ After the countercurrent ultrasonic extraction is completed, the decolorized corn gluten powder is discharged from the slag discharge port of the continuous countercurrent ultrasonic extractor, and the decolorized corn gluten powder is used for subsequent enzymatic hydrolysis; it is discharged from the liquid discharge port of the...

Embodiment 2

[0034] (1) Pretreatment of corn gluten meal

[0035] ①Crush the corn gluten powder, pass through a 40-mesh sieve, and input it into the extraction tube from the feed port. The liquid ratio is 1:6.

[0036] ②Corn gluten powder and ethanol were subjected to countercurrent ultrasonic extraction in the extraction tube of a continuous countercurrent ultrasonic extraction machine for 60 minutes. The conditions of ultrasonic extraction were: temperature 40°C, ultrasonic frequency 40kHz.

[0037]③ After the countercurrent ultrasonic extraction is completed, the decolorized corn gluten powder is discharged from the slag discharge port of the continuous countercurrent ultrasonic extractor, and the decolorized corn gluten powder is used for subsequent enzymatic hydrolysis; it is discharged from the liquid discharge port of the continuous countercurrent ultrasonic extractor for extraction liquid.

[0038] ④ The extract is filtered to obtain a filtrate, concentrated to recover ethanol, a...

Embodiment 3

[0045] (1) Pretreatment of corn gluten meal

[0046] ①Crush corn gluten powder, pass through a 60-mesh sieve, and input it into the extraction tube from the feed port, and at the same time, input ethanol with a pH of 8.5, a concentration of 85%, and a temperature of 50°C into the extraction tube from the liquid inlet of the extractor , The ratio of solid to liquid is 1:8.

[0047] ②Corn gluten powder and ethanol were subjected to countercurrent ultrasonic extraction in the extraction tube of a continuous countercurrent ultrasonic extraction machine for 90 minutes. The conditions of ultrasonic extraction were: temperature 50°C, ultrasonic frequency 40kHz.

[0048] ③ After the countercurrent ultrasonic extraction is completed, the decolorized corn gluten powder is discharged from the slag discharge port of the continuous countercurrent ultrasonic extractor, and the decolorized corn gluten powder is used for subsequent enzymatic hydrolysis; it is discharged from the liquid discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com