Method for preparing biological diesel oil from immobilized lipase-porous membrane biological reactor

A technology of immobilized lipase and bioreactor, which is applied in the field of membrane separation, can solve the problems of no process and practical application, and achieve the effects of avoiding solvent cleaning and batch feeding, high enzyme activity and stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

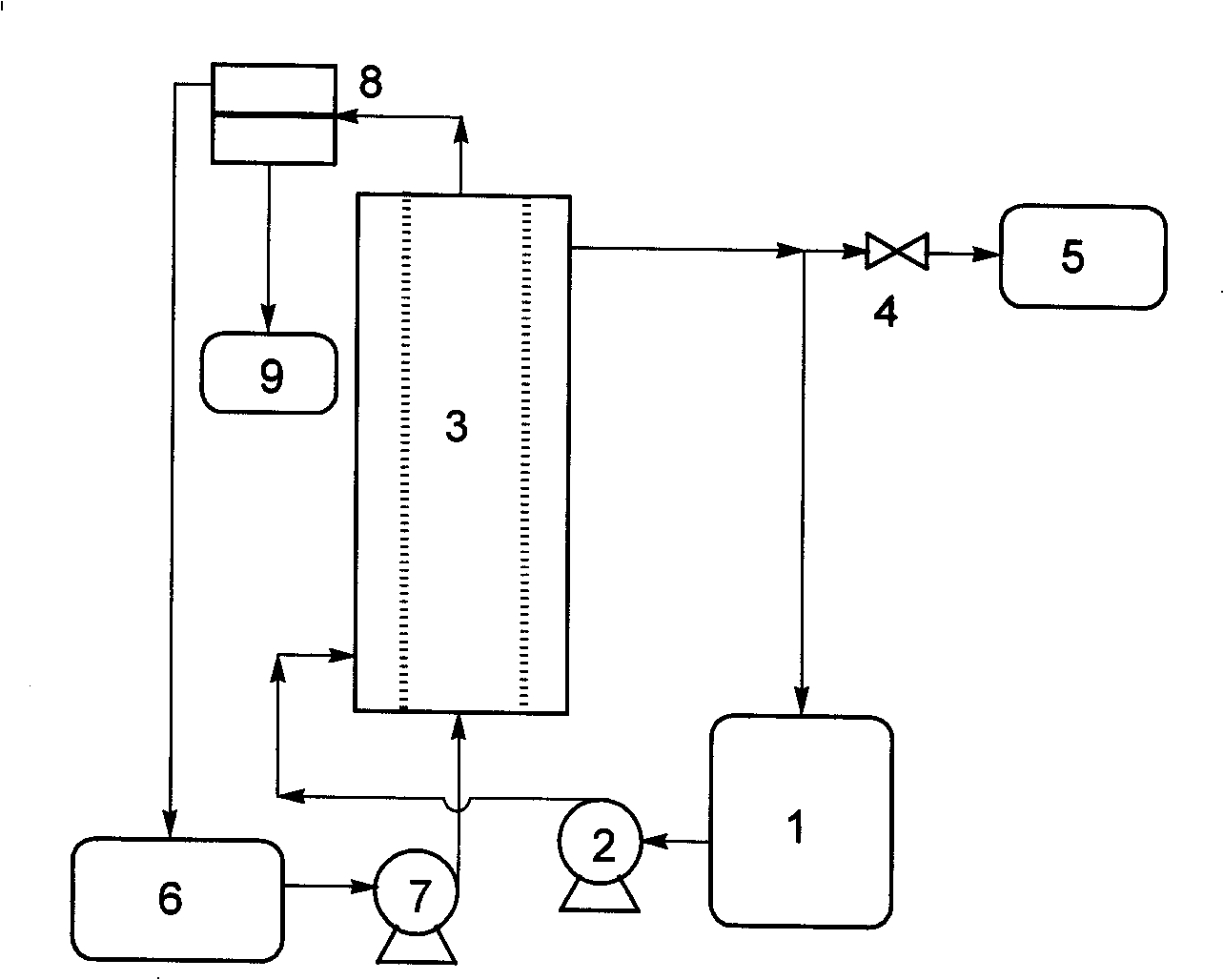

[0020] A polyacrylonitrile porous membrane (molecular weight cut-off 10kDa) immobilized lipase (from Candida antarctica) was made into a membrane module, which was connected to an enzyme-membrane bioreactor. Inject the mixture of 2.5L fish oil and 2.5L methanol into the raw material storage tank 1, and go through the pump 2 to the shell side of the membrane module 3 at a flow rate of 5L / h; the water flows from the storage tank 6 through the pump 7 to the tube side of the membrane module 3 at a flow rate of 2L / h. The yield of biodiesel is about 91% after 4h circulation.

Embodiment 2

[0022] A polysulfone porous membrane (molecular weight cut-off 1 kDa) immobilized lipase (derived from Rhizomucor miehei) was made into a membrane module, which was connected to an enzyme-membrane bioreactor. The mixture of 2L lard and 3L ethanol is injected into the raw material storage tank 1, and the membrane module 3 shell passes through the pump 2, and the flow rate is 5L / h; the water flows from the storage tank 6 through the pump 7, and the membrane module 3 tube pass, the flow rate is 10L / h h. The yield of biodiesel is about 93% after 4h circulation.

Embodiment 3

[0024] A polysulfone porous membrane (molecular weight cut-off 10 kDa) immobilized lipase (derived from Thermomyces lanuginosus) was made into a membrane module, which was connected to an enzyme-membrane bioreactor. The mixture of 2L castor oil and 3L methanol is injected into the raw material storage tank 1, and the membrane module 3 shell side is passed through the pump 2, and the flow rate is 5L / h; the water is passed from the storage tank 6 through the pump 7 and the membrane module 3 tube side, and the flow rate is 2L / h. h. The yield of biodiesel is about 92% after 4h circulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com