Method for producing amino-acid-containing water-soluble fertilizer

A technology for water-soluble fertilizers and production methods, applied in the direction of inorganic fertilizers, calcium fertilizers, liquid fertilizers, etc., can solve the problem that DL-pyroglutamic acid cannot be directly applied to plants, etc., and achieves wide application range and high substrate conversion rate , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

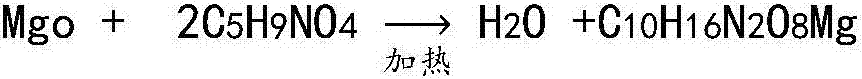

Image

Examples

Embodiment 1

[0036] Add DL-pyroglutamic acid to hydrochloric acid with a concentration of 10% in a weight ratio of 1:2, and add it to the reaction kettle, and seal the feeding port;

[0037] Turn on the steam to ensure that the steam pressure does not exceed 0.3Mpa, DL-pyroglutamic acid and hydrochloric acid are slightly boiled and hydrolyzed for 4 hours under the action of steam, and after the reaction is completed, put the hydrolyzate into the chelation tank;

[0038] Stir the hydrolyzate, and slowly add magnesium oxide with a content of 85% in the chelation tank, and its weight is 5% of the weight of DL-pyroglutamic acid;

[0039] Adding quicklime with a calcium content of 65% to the chelation tank to adjust the pH value of the hydrolyzate to 6.0;

[0040] Adjust the temperature in the chelation tank to 75-78°C, and keep it warm for 2 hours;

[0041] The plate and frame filter press is used to circulate and filter the chelated hydrolyzate until there is no visible foreign matter, and t...

Embodiment 2

[0044] Add DL-pyroglutamic acid to 10% hydrochloric acid in a weight ratio of 1:2 into the reaction kettle, and seal the feeding port;

[0045] Turn on the steam to ensure that the steam pressure does not exceed 0.3Mpa, DL-pyroglutamic acid and hydrochloric acid are slightly boiled and hydrolyzed for 4 hours under the action of steam, and after the reaction is completed, put the hydrolyzate into the chelation tank;

[0046] Stir the hydrolyzate, and slowly add magnesium oxide with a content of 85% in the chelation tank, and its weight is 8% of the weight of DL-pyroglutamic acid;

[0047] Adding quicklime with a calcium content of 65% to the chelation tank to adjust the pH value of the hydrolyzate to 6.3;

[0048] Adjust the temperature in the chelation tank to 79-82°C, and keep it warm for 2 hours;

[0049] The plate and frame filter press is used to circulate and filter the chelated hydrolyzate until there is no visible foreign matter, and the obtained filtrate is a water-so...

Embodiment 3

[0052] Add DL-pyroglutamic acid to 10% hydrochloric acid in a weight ratio of 1:2 into the reaction kettle, and seal the feeding port;

[0053] Turn on the steam to ensure that the steam pressure does not exceed 0.3Mpa, DL-pyroglutamic acid and hydrochloric acid are slightly boiled and hydrolyzed for 4 hours under the action of steam, and after the reaction is completed, put the hydrolyzate into the chelation tank;

[0054] Stir the hydrolyzate, and slowly add magnesium oxide with a content of 85% in the chelation tank, whose weight is 10% of the weight of DL-pyroglutamic acid;

[0055] Add unslaked lime in the chelating tank, adjust the pH value of hydrolyzate to be 6.5;

[0056] Adjust the temperature in the chelation tank to 81-84°C, and keep it warm for 2 hours;

[0057]The plate and frame filter press is used to circulate and filter the chelated hydrolyzate until there is no visible foreign matter, and the obtained filtrate is the amino acid-containing water-soluble fert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com