Recombinant strain for producing L-2-aminobutyric acid and preparing method and application thereof

A technology of aminobutyric acid and recombinant bacteria, applied in the biological field, can solve the problems of difficult purification of 2-aminobutyric acid and inability to meet the needs of industrial production, and achieve the effect of improving substrate conversion rate, improving utilization rate, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1. Construction of L-2-aminobutyric acid primary engineering bacteria ABA1 and ABA2

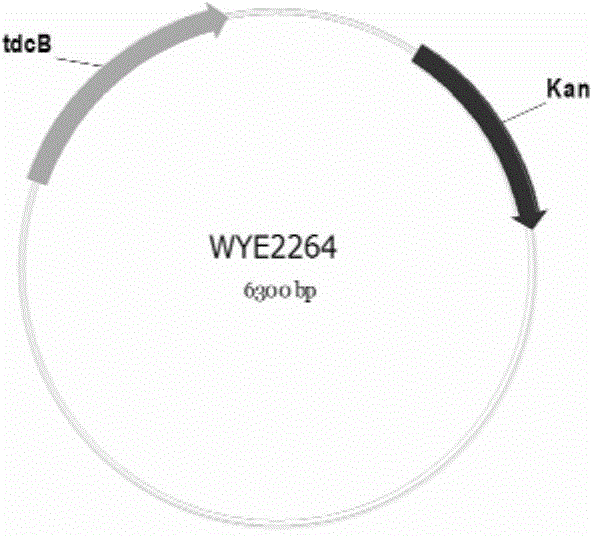

[0036] 1. Construction of Threonine Deaminase Expression Plasmid

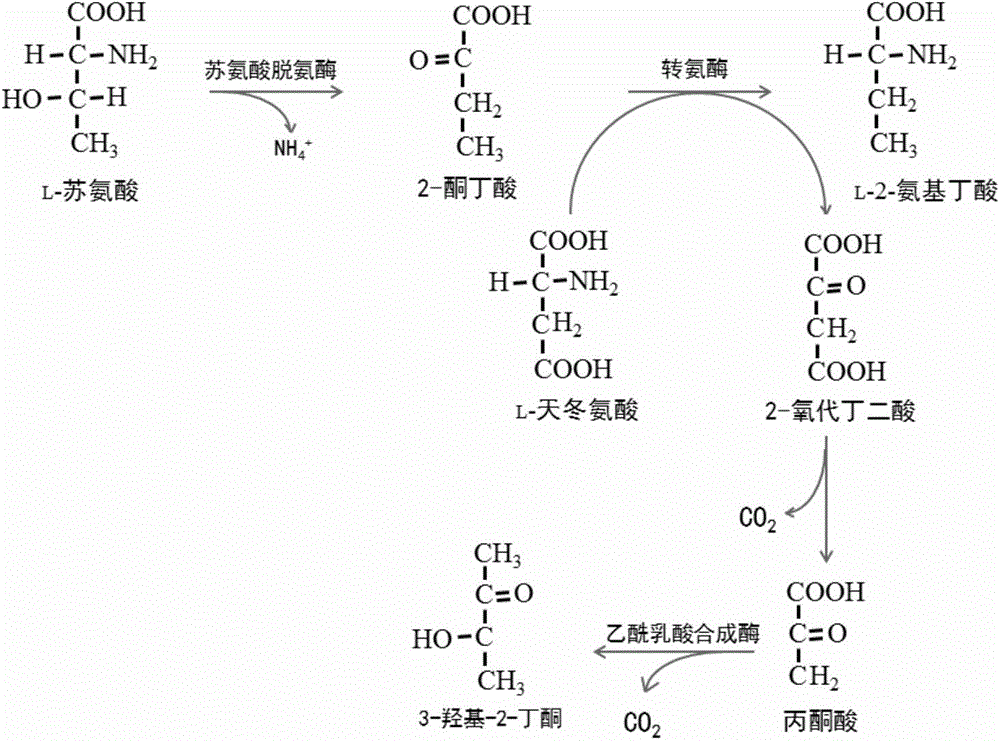

[0037] Threonine deaminase catalyzes the deamination of threonine to produce 2-ketobutyrate, and overexpression of threonine deaminase promotes the conversion of threonine to 2-ketobutyrate.

[0038] The primers were designed according to the ilvA gene of E.coli K12W3110 in Genbank, the E.coli K12W3110 genome was used as the template, WY1423 and WY1424 were used as primers, and the high-fidelity polymerase KAPA HiFiTM HotStar was used for PCR amplification. The PCR was performed as follows: 94 Denaturation at ℃ for 30 s (seconds), annealing at 54 ℃ for 30 s (seconds), and extension at 72 ℃ for 30 s (seconds) (30 cycles), PCR amplified to obtain a 1560 bp PCR product (sequence 1), the DNA fragment obtained by PCR was subjected to agar After separation and purification by sugar gel electrophoresis, the recovered fragmen...

Embodiment 2

[0060] Example 2, L-2-Aminobutyric acid primary engineering bacteria whole cell catalyzed production of L-2-aminobutyric acid

[0061] L-2-aminobutyric acid primary engineering bacteria ABA1 (BL21 / pET28a-tdcB-ilvE) and ABA2 (BL21 / pET28a-ilvA-ilvE) are used to catalyze the production of L-2-aminobutyric acid.

[0062] The specific seed culture medium is as follows: peptone 10g / L, yeast powder 5g / L, NaCl 10g / L; kanamycin 50mg / L.

[0063] The specific medium for the growth stage of the bacteria is as follows: yeast powder, 10.00g / L; K 2 HPO 4 ·3H 2 O, 0.90g / L; KH 2 PO 4 , 1.14g / L; (NH4) 2 SO 4 , 10.00g / L; MgSO 4 ·7H 2 O, 0.30g / L; trace element (TMS) stock solution, 5.00mL / L.

[0064] Of which TMS storage solution: FeSO 4 ·7H 2 O, 10.000g / L; CaCl 2 , 1.350g / L; ZnSO 4 ·7H 2 O, 2.250g / L; MnSO 4 ·4H 2 O, 0.500g / L; CuSO 4 ·5H 2 O, 1.000g / L; (NH 4 ) 6 Mo 7 O 24 ·4H 2 O, 0.106g / L; Na 2 B 4 O 7 ·10H 2 O, 0.230g / L; CoCl 2 ·6H 2 O, 0.480 g / L; 35% HCl, 10.000 mL / L.

[0065] Buffer: KH 2 PO 4 , 1.36g / ...

Embodiment 3

[0085] Example 3 Construction of L-2-aminobutyric acid engineering bacteria ABA3, ABA4, ABA5

[0086] 1. Construction of multiple transaminase expression plasmids

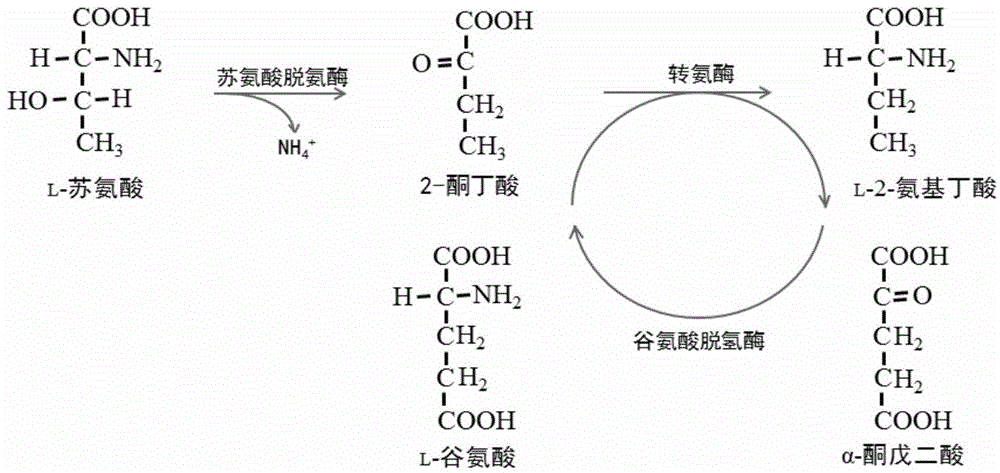

[0087] Tyrosine aminotransferase TyrB catalyzes the transamination reaction of aromatic amino acids, putrescine aminotransferase PatA catalyzes the transamination reaction of putrescine, and valine pyruvate aminotransferase AvtA catalyzes the formation of alanine from valine and pyruvate. 3-Methyl-2-ketobutyric acid, in order to compare the difference in the catalytic ability of the three aminotransferases to catalyze 2-ketobutyric acid to 2-aminobutyric acid, the expression plasmids and strains containing the three aminotransferases were constructed respectively.

[0088] Using the E.coli K12W3110 genome as a template, using WY1405 and WY1406 as primers, a 1256bp PCR product (SEQ ID No. 8) was amplified; using WY1408 and WY1409 as primers, a 1436bp PCR product was amplified (SEQ ID No. 10). ); Using WY1411 and WY1412 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com