Production method of agricultural gamma-polyglutamic acid

A polyglutamic acid and production method technology, applied in the field of agricultural microorganisms, can solve the problems of high cost of polyglutamic acid, low substrate conversion rate, and ineffective effects, etc., to achieve improved substrate conversion rate, The effect of shortening the fermentation cycle and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A production method of agricultural grade gamma-polyglutamic acid, comprising the following steps:

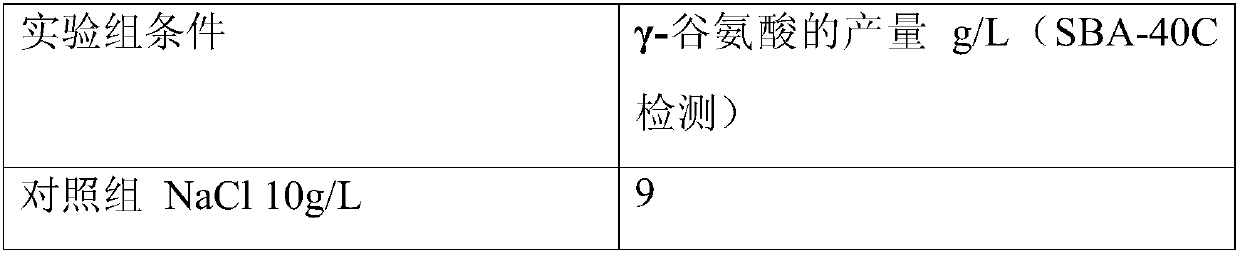

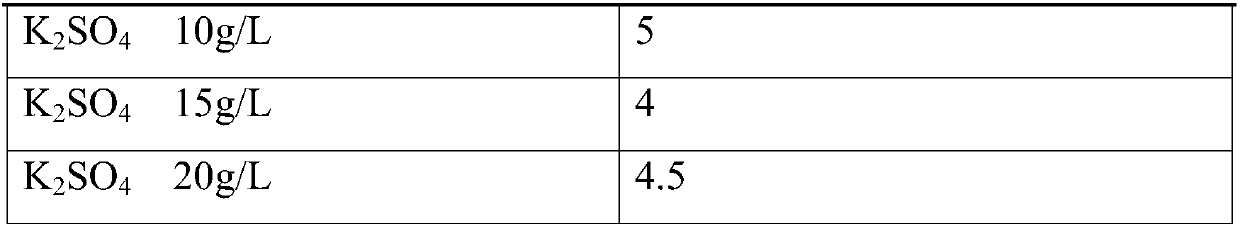

[0043] (1) Strain activation: the original strain of Bacillus licheniformis CGMCC NO.3336 was inoculated on the slant medium, and cultivated at 37°C for 18 hours to prepare mature slant seeds; the composition of the slant medium was: tryptone 10g / L, yeast Dip powder 5g / L, NaCl 10g / L, agar powder 20g / L, and the balance is water.

[0044] Bacillus licheniformis (Bacillus licheniformis) TKPG091, this bacterial strain has been preserved on October 14, 2009 at the General Microbiology Center of the Chinese Academy of Sciences Institute of Microbiology, China Microbiological Culture Collection Management Committee, No. 1, Beichen West Road, Chaoyang District, Beijing. The deposit number is CGMCC No.3336;

[0045] (2) Preparation of seed solution: Inoculate the activated slant seeds into a 500mL Erlenmeyer flask containing 50mL of liquid medium, cultivate at 37°C at a shaker s...

Embodiment 2

[0051] A production method of agricultural grade gamma-polyglutamic acid, comprising the following steps:

[0052] (1) Strain activation: the original strain of Bacillus licheniformis was inoculated on the slant medium, and cultured at 30°C for 16 hours to prepare activated slant seeds; the composition of the slant medium was: tryptone 10g / L, yeast extract powder 5g / L, NaCl10g / L, agar powder 20g / L, and the balance is water.

[0053] Bacillus licheniformis (Bacillus licheniformis) TKPG091, this bacterial strain has been preserved on October 14, 2009 at the General Microbiology Center of the Chinese Academy of Sciences Institute of Microbiology, China Microbiological Culture Collection Management Committee, No. 1, Beichen West Road, Chaoyang District, Beijing. The deposit number is CGMCC No.3336;

[0054] (2) Preparation of seed liquid; Inoculate the activated slant seeds in a 500mL Erlenmeyer flask with 50mL of liquid medium, cultivate at 37°C at a shaker speed of 220rpm for 1...

Embodiment 3

[0060] A production method of agricultural grade gamma-polyglutamic acid, comprising the following steps:

[0061] (1) Strain activation: the original strain of Bacillus licheniformis was inoculated on the slant medium, and cultured at 35°C for 17 hours to prepare activated slant seeds; the composition of the slant medium was: tryptone 10g / L, yeast extract powder 5g / L, NaCl10g / L, agar powder 20g / L, and the balance is water.

[0062]Bacillus licheniformis (Bacillus licheniformis) TKPG091, this bacterial strain has been preserved on October 14, 2009 at the General Microbiology Center of the Chinese Academy of Sciences Institute of Microbiology, China Microbiological Culture Collection Management Committee, No. 1, Beichen West Road, Chaoyang District, Beijing. The deposit number is CGMCC No.3336;

[0063] (2) Preparation of seed solution; inoculate the activated slant seeds in step (1) in a 500mL Erlenmeyer flask with 50mL of liquid medium, cultivate at 37°C at a shaker speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com