Surface immobilized yeast fermentation technology

A technology of immobilized yeast and technology, which is applied in the field of surface immobilized yeast fermentation, can solve problems such as poor effect, and achieve the effect of low cost, high substrate conversion rate and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of fuel ethanol by using synthetic medium as fermentation raw material and adopting bamboo fiber immobilized yeast

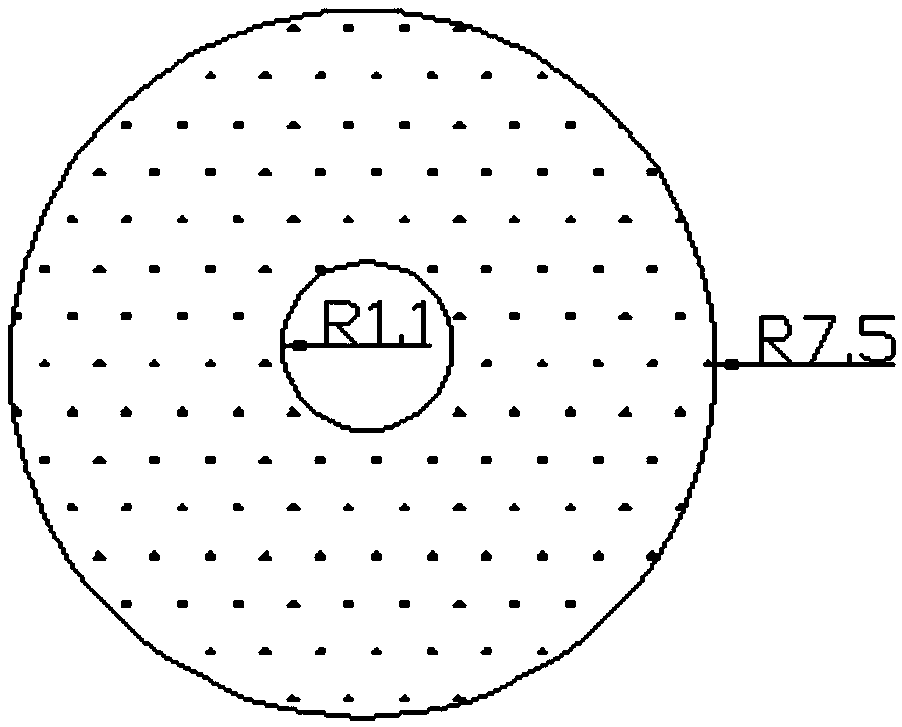

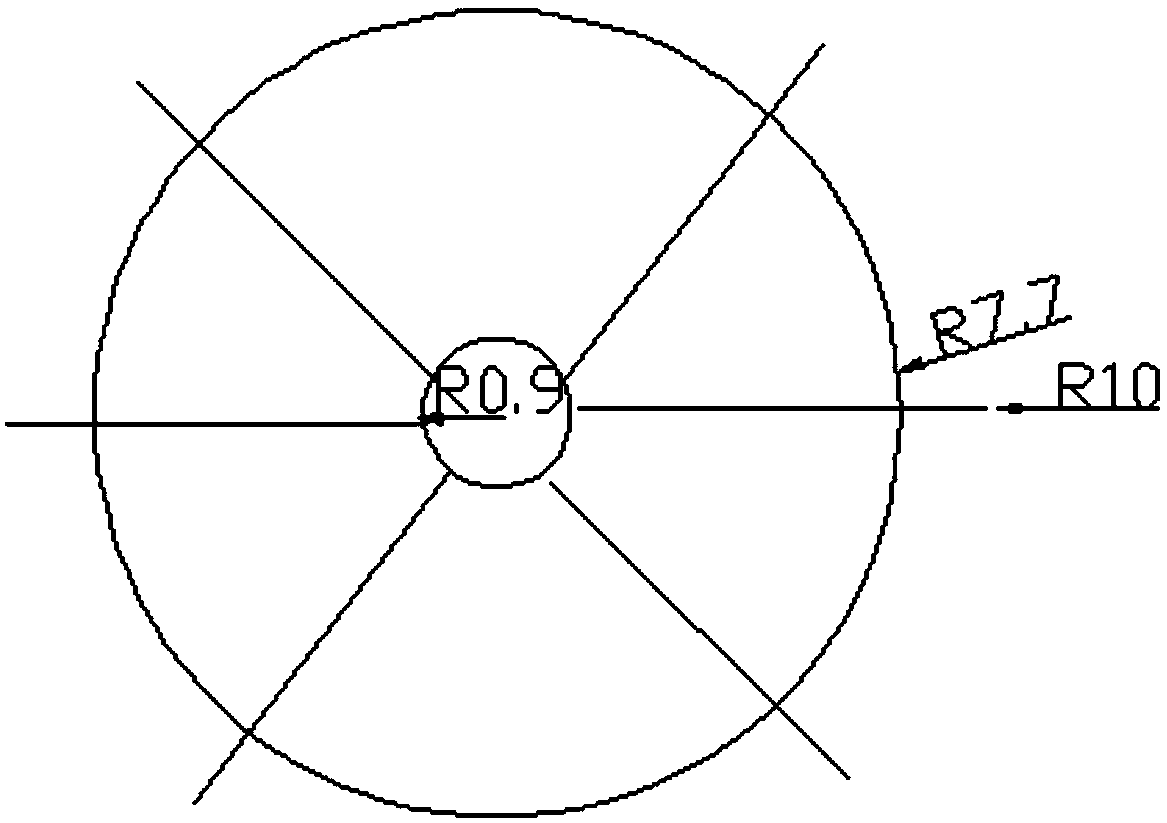

[0044] First, put the bamboo fiber (thickness 0.15cm) cut into 15cm in diameter into polytetrafluoroethylene (PTFE) made into a 20cm in diameter spherical grid as shown in Figure 1, and prepare an immobilized carrier (Figure 2); then Place the immobilization medium at 150cm 2 The filling amount per L is placed in a 15L reactor with a height-to-diameter ratio of 2:1. Then the cultured strains were added to the fermenter, and fixed at a flow rate of 30 L / h for 36 hours. Until the bacterial cell adsorption concentration is 200 million / ml. Then drain to waste. Then feed the fermentation medium (glucose concentration is 220g / L), the liquid content is 75%, and carry out circular fermentation, wherein the temperature is 33°C, the pH of the fermentation broth is 4.5, and the flow rate is 30L / h. The average fermentation period of 5 batche...

Embodiment 2

[0045] Example 2 Production of fuel ethanol using cassava liquefied mash medium as fermentation raw material and cotton fiber immobilized yeast

[0046] First, put the cotton fiber cut into a diameter of 20cm into a spherical grid with a diameter of 25cm made of polyethylene to prepare an immobilization medium; 2 The filling amount per L is placed in a 15L reactor with an aspect ratio of 1.8:1. Then the cultured strains were added to the fermenter, and fixed at a flow rate of 15 L / h for 48 hours. Until the bacterial cell adsorption concentration is 250 million / ml. Then prepare cassava liquefied mash: the ratio of solid to liquid is 1:2.5, add liquefaction enzyme (15U / g cassava dry weight) to liquefy at 85°C for 2 hours, and discharge the immobilized seed waste liquid after cooling. Then add cassava liquefied mash, and add glucoamylase (180U / g cassava dry weight), the liquid content is 75%, and carry out circular fermentation, wherein the temperature is 35 ° C, the pH of the ...

Embodiment 3

[0047] Example 3 Production of fuel ethanol using high-concentration cassava liquefied mash medium as fermentation raw material and immobilized yeast with cotton fiber

[0048] Firstly, the cotton fiber cut into a diameter of 8 cm was put into a spherical grid with a diameter of 12 cm made of polyvinyl fluoride to prepare an immobilization medium; 2The filling amount per L is placed in a 50L reactor with an aspect ratio of 1.8:1. Then the cultured strains were added to the fermenter, and fixed at a flow rate of 30 L / h for 48 hours. Until the bacterial cell adsorption concentration is 200 million / ml. Then prepare cassava liquefied mash: the ratio of solid to liquid is 1:2, add liquefying enzyme (18U / g cassava dry weight) to liquefy at 90°C for 1.5 hours, and discharge the immobilized seed waste liquid after cooling. Then add cassava liquefied mash, and add glucoamylase (200U / g cassava dry weight), the liquid content is 75%, and carry out circular fermentation, wherein the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com