Novel process for fermenting coenzyme Q10 based on online oxygen consumption rate control

A technology of oxygen consumption rate and new process, applied in the field of fermentation, can solve the problem of not being able to become the control index of oxygen supply level, etc., and achieve the effects of high specific production rate, high substrate conversion rate, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

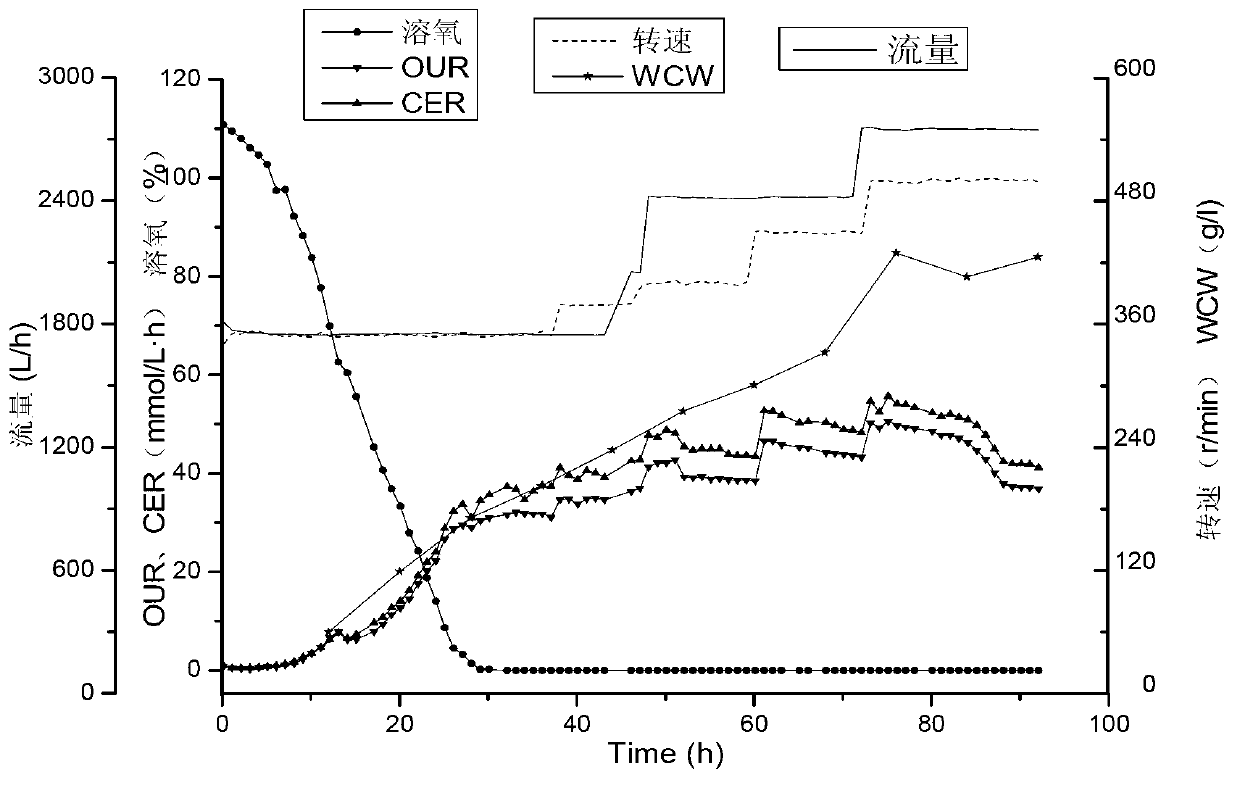

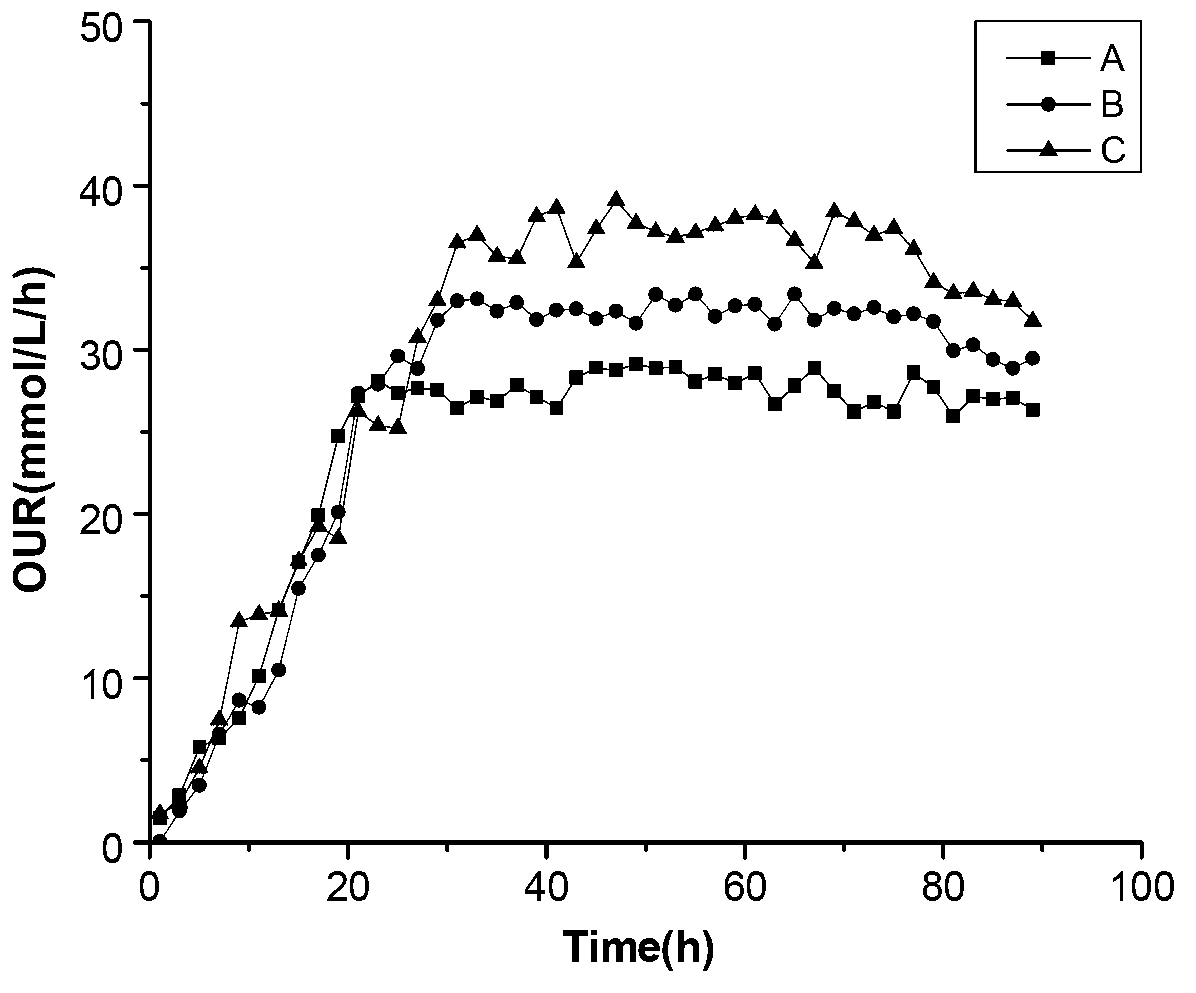

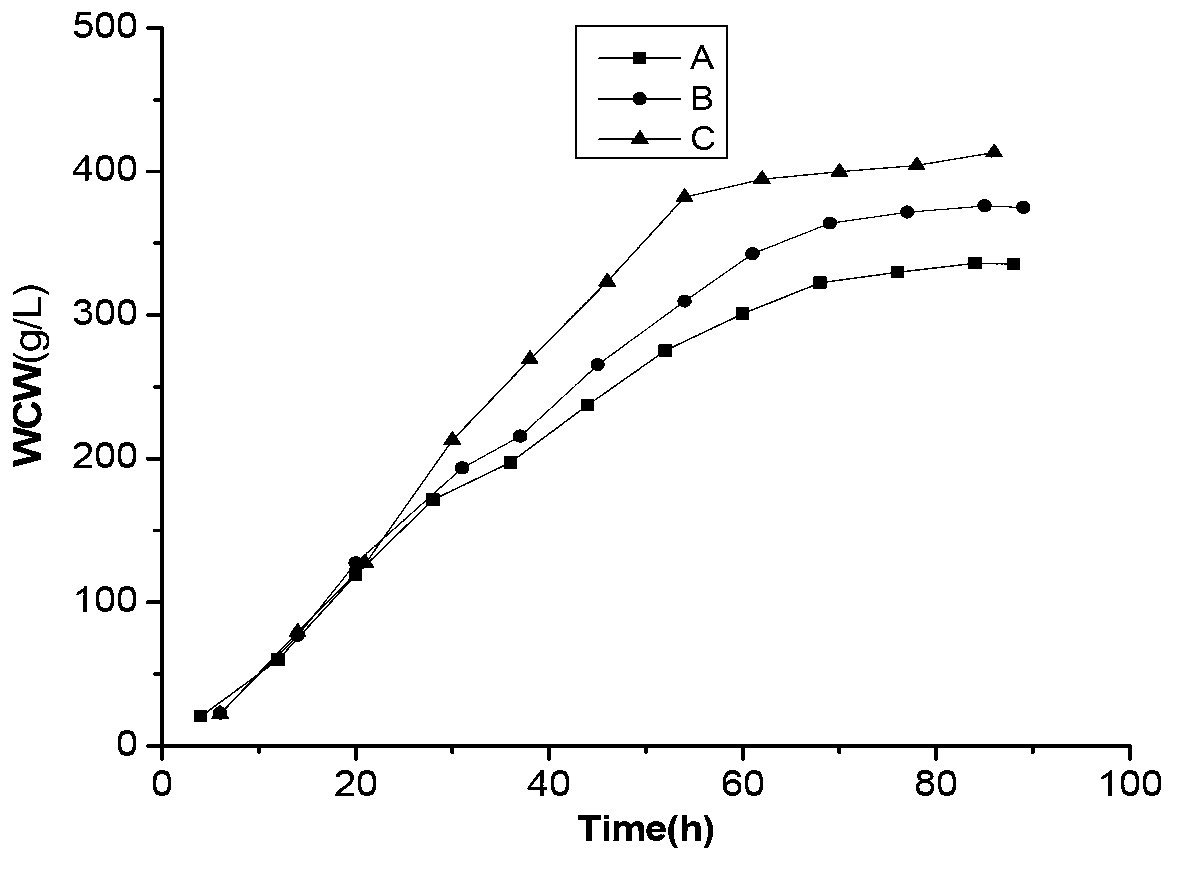

Examples

Embodiment 1

[0053] 1 Materials and methods

[0054] 1.1 Bacteria and culture medium

[0055] Species: Rhodobacter sphaeroides, the deposit number is CGMCC No.5997, CGMCC No.5998, CGMCC No.5999.

[0056] Seed medium (g / L): 1g yeast powder, 1gNH 4 Cl, 1g sodium chloride, 2.8mg ferric citrate, 0.6g KH 2 PO 4 ,0.9g K 2 HPO 4 ,0.25g MgSO 4 ,0.1g CaCl 2 , 0.5ug biotin, pH 7.0

[0057] Fermentation medium (g / L): 8g yeast powder, 1g NH4Cl, 1g sodium chloride, 5mg ferric citrate, 0.6g KH 2 PO 4 ,0.9gK 2 HPO 4 ,0.5g MgSO 4 ,0.1g CaCl 2 , 3ug biotin, pH 7.0.

[0058] Feed medium 1 (g / L): 200gKH 2 PO 4 .

[0059] Feed medium 2 (g / L): 700 g glucose.

[0060] 1.2 Reagents and instruments

[0061] Reagents: corn steep liquor (Shanghai Xiwang Starch Sugar Co., Ltd.), glucose (Shanghai Sugar Co., Ltd.), and other reagents are of domestic analytical grade.

[0062] Instrument: Model 722 UV-Vis Spectrophotometer; HPLC 1100 (Agilent); Tail Gas Mass Spectrometer: American Extrel Process Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com