Recombinant corynebacterium glutamicum for high production of gamma-aminobutyric acid as well as construction method and application thereof

A technology of Corynebacterium glutamicum and GABA, applied in the direction of microorganism-based methods, recombinant DNA technology, biochemical equipment and methods, etc., can solve the problems of complex components of fermentation broth, high risk factor, and many side reactions, etc. Achieve the effect of good industrial application prospect, high substrate conversion rate and simple fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Construction of recombinant Corynebacterium glutamicum C. glutamicum NJ-M6.

[0035] Strains: Corynebacterium glutamicum C. glutamicum CICC10240.

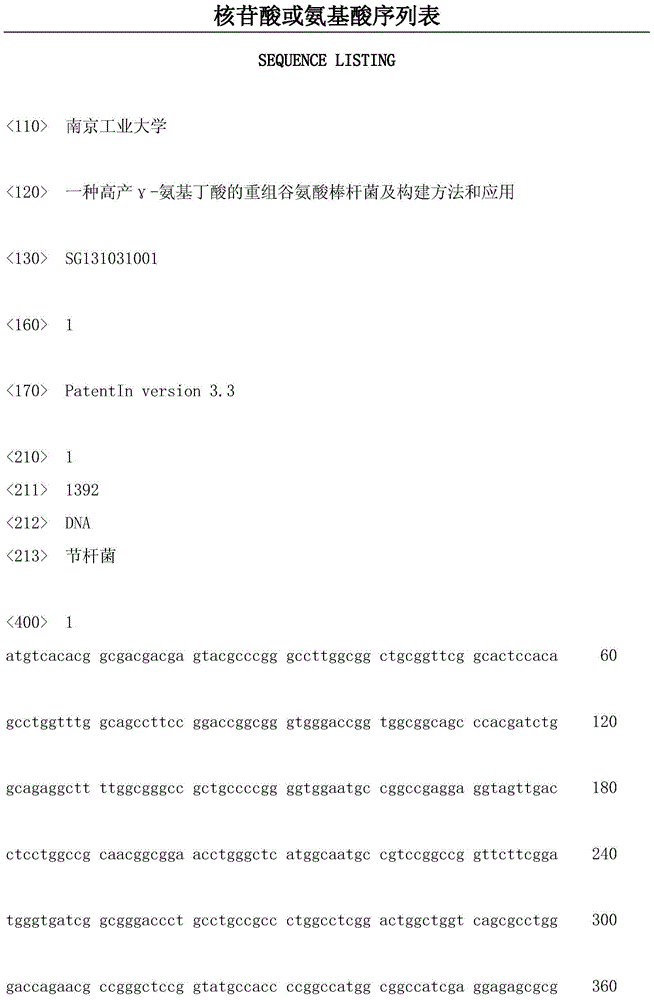

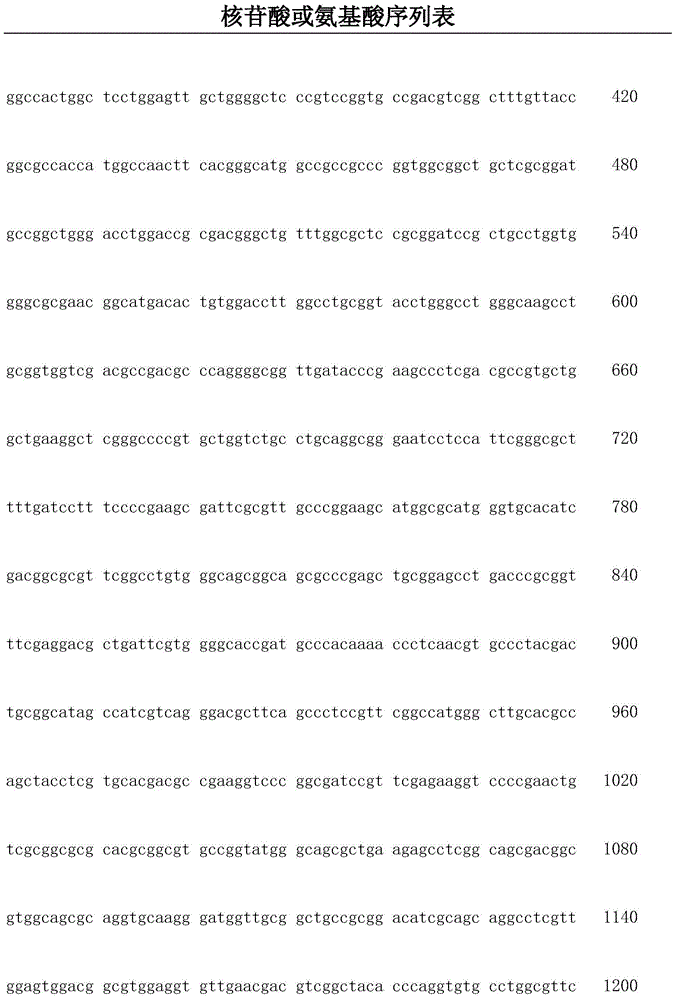

[0036] Exogenous gene: the glutamate decarboxylase gene gad derived from Arthrobacter (strain number; CGMCC No.3584).

[0037] Vector: E.coli / C. glutamicum shuttle vector pXJ19.

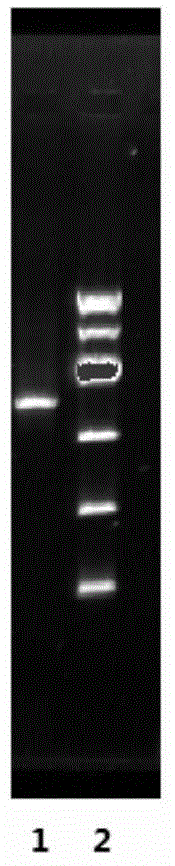

[0038] Using the Arthrobacter CGMCC3584 genome as a PCR template, the glutamic acid decarboxylase gene gad was amplified by PCR; figure 1 , the size of the gad gene is 1392bp. Connect the two ends of the gad fragment to EcoRI and HindIII sites respectively, and the primers are:

[0039] Sense strand: 5'-TCGCGGATCCGAATTCATGTCACACGGCGACGACGA-3';

[0040] Antisense strand: 3'-TGCGGCCGCAAAGCTTTCAGCTTCCGCGTACTGCGG-5'.

[0041] The obtained glutamic acid decarboxylase gene gad product was double-enzymatically digested and loaded into the shuttle vector pXJ19 to form a fusion fragment, which was then identified by enzyme digestion and sequ...

Embodiment 2

[0045] This example illustrates the process of producing γ-aminobutyric acid by fed-feed fermentation of Corynebacterium glutamicum C. glutamicum NJ-M6.

[0046] The medium formula described in this embodiment (% is mass percent):

[0047] Solid plate medium: 1L distilled water contains: 1L distilled water contains 10g peptone, 5g yeast powder, 10g sodium chloride, 15g agar powder, pH7.0.

[0048] Seed medium: 1L distilled water containing 30g glucose, 10g ammonium sulfate, 5g peptone, 3.5g corn steep liquor, 1.0g potassium dihydrogen phosphate, 1.0g sodium chloride, pH=7.0.

[0049] Fermentation medium: 1L distilled water containing 30g glucose, 10g sodium glutamate, 26g ammonium sulfate, 20g corn steep liquor, 4.5g potassium dihydrogen phosphate, 2.5g magnesium sulfate, pH=7.0.

[0050] Inoculate the Corynebacterium glutamicum NJ-M6 preserved in the glycerol tube onto the LB medium at a culture temperature of 30 degrees for 8-12 hours; culture the Corynebacterium glutamicum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com