A strain of Bacillus producing alginate lyase and its application

An alginate lyase and Bacillus technology, applied in the directions of lyase, bacteria, microorganism-based methods, etc., can solve the problems of unsafe strains, narrow enzyme substrate spectrum, poor enzyme stability, etc., and achieve high activity and simple preparation. , the effect of high substrate conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

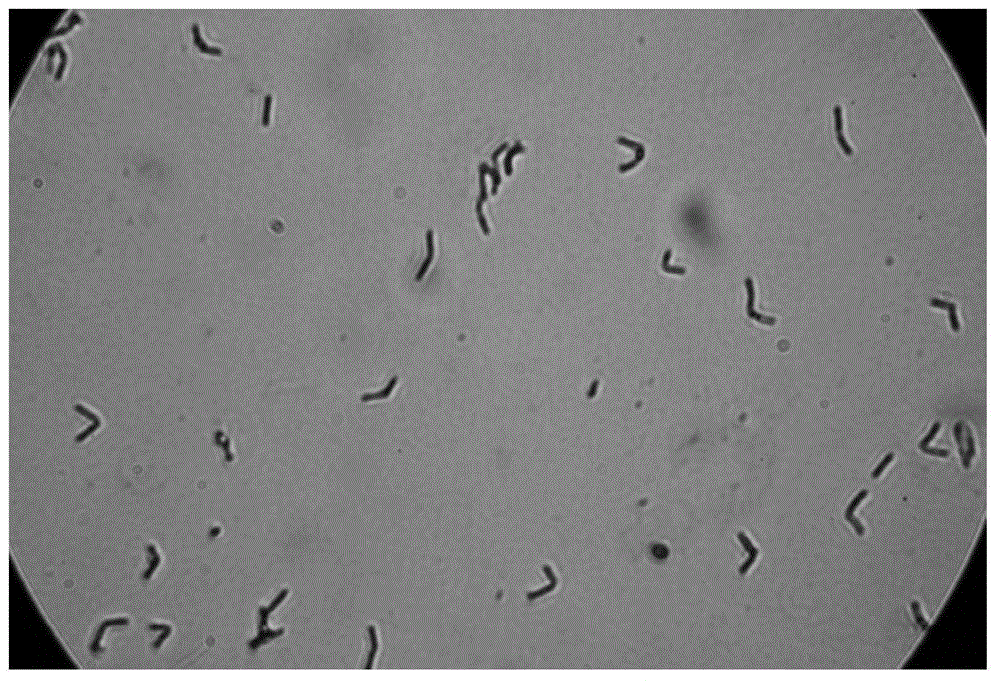

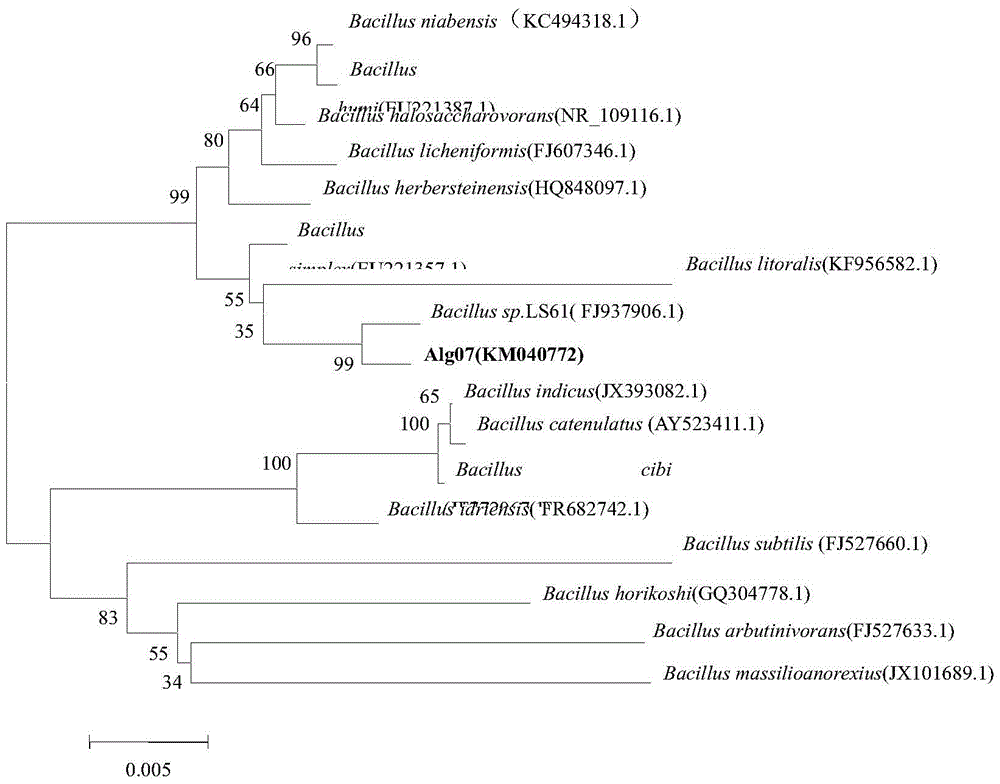

[0025] Example 1: Screening identification and preservation of Bacillus sp. Alg07

[0026] (1) Screening of strains

[0027] The rotten kelp samples were obtained from Weihai Qingyutan Sea Treasure Farm, and 5g samples were put into a 250mL Erlenmeyer flask filled with 50mL enrichment medium, and fermented by shaking the flask at 30°C and 180r / min. After culturing for 48 h, transfer 5 mL of the culture solution to another 250 mL Erlenmeyer flask filled with 50 mL of fresh enrichment medium, and pass 5 times continuously. The culture medium of continuous acclimatization for 5 generations was mixed with sterile saline according to 10 -3 to 10 -7 Carry out gradient dilution, take 0.1mL of the diluted solution and spread it on the primary screening solid plate, and after 48 hours of constant temperature incubation at 30°C, use the plate streaking method to determine the strains of single colonies that can grow on the primary screening medium and produce transparent circles. sep...

Embodiment 2

[0038] Example 2, Bacillus sp. (Bacillus sp.) Alg07 CGMCC No.9391 production medium composition optimization of alginate lyase

[0039] Put 50ml of fermentation medium into a 250mL conical flask, sterilize with high-temperature steam at 121°C for 30 minutes, and aseptically inoculate the seed liquid cultivated to the late logarithmic phase into the conical flask with an inoculum volume of 2%, at 30°C and 180r / min Under culture for 48h, the enzyme activity was measured, and all experiments were designed in parallel three times. The results of the previous optimization step are used in subsequent experiments.

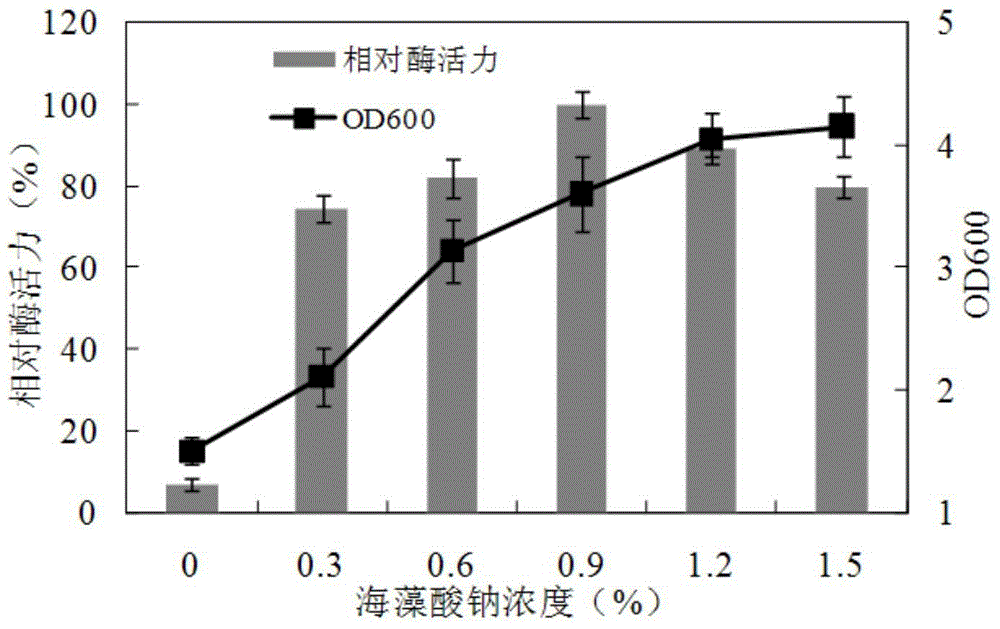

[0040] (1) Effect of carbon source on enzyme production of Bacillus sp. Alg07 CGMCC No.9391

[0041] Using 0.5% glucose, lactose, mannose, D-mannitol, maltose, starch and sodium alginate as the sole carbon source to prepare the fermentation medium, the results showed that the strain Alg07 could only produce enzymes when sodium alginate was the sole carbon source , indic...

Embodiment 3

[0045] Example 3, Optimization of fermentation conditions for the production of alginate lyase by Bacillus sp. Alg07 CGMCC No.9391

[0046] The optimized fermentation medium formula was used to prepare the fermentation medium, and the optimal conditions for the production of alginate lyase by strain Alg07 were optimized through single factor experiments. All experiments were designed in triplicate. The results of the previous optimization step are used in subsequent experiments.

[0047] (1) Effect of culture temperature on enzyme production of Bacillus sp. Alg07 CGMCC No.9391

[0048] Temperature is an important environmental factor affecting the growth and metabolism of the strain. Under the optimized medium conditions, the strain was fermented and cultured at 15°C, 20°C, 25°C, 30°C, 35°C, and 40°C for 48 hours, and the alginate lyase in the fermentation broth was detected. Activity, the results showed that when the temperature was 20°C to 30°C, the enzyme activity was high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com