Vanadium manganese composite catalyst for removing nitrogen oxide in incineration gas and preparation method thereof

A composite catalyst, nitrogen oxide technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., to achieve a wide reaction temperature range, reduce reaction temperature, increase ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: adopt solvothermal method

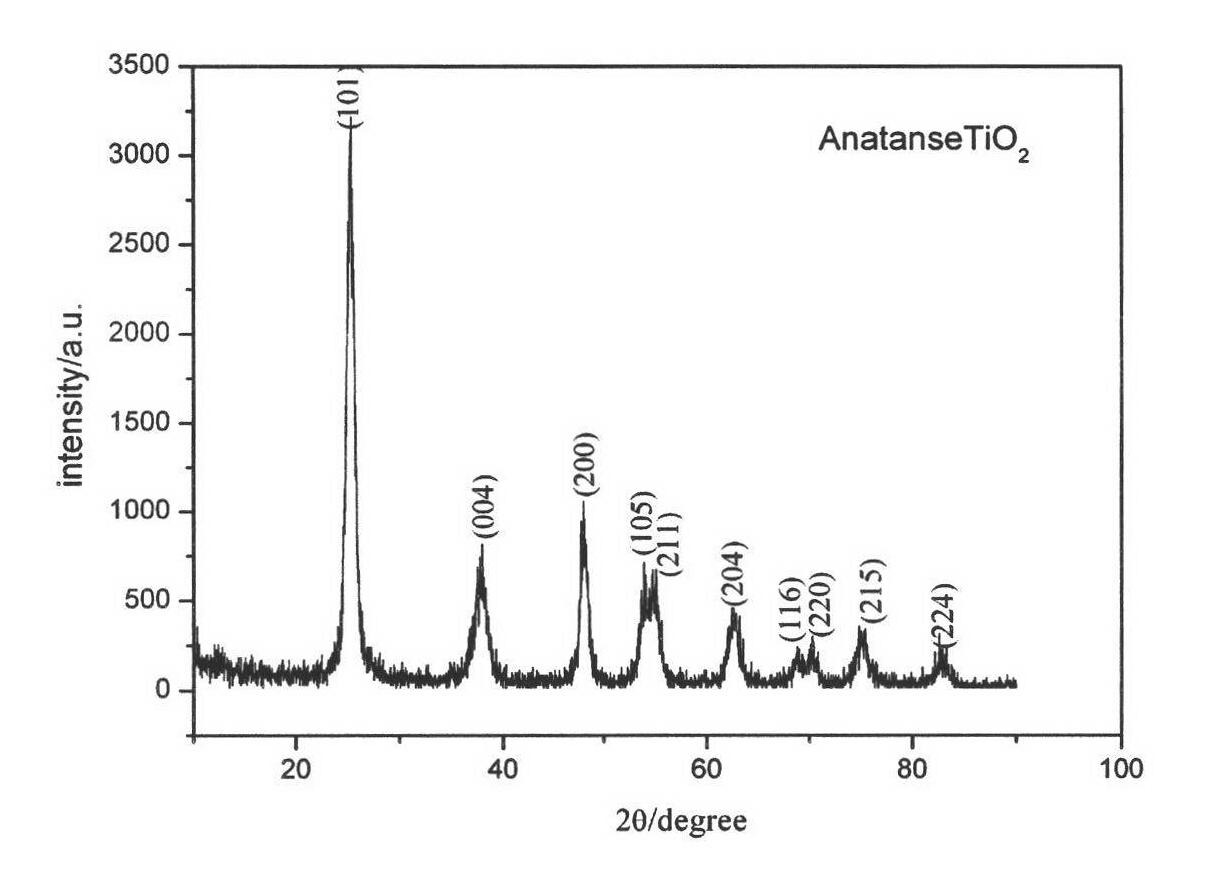

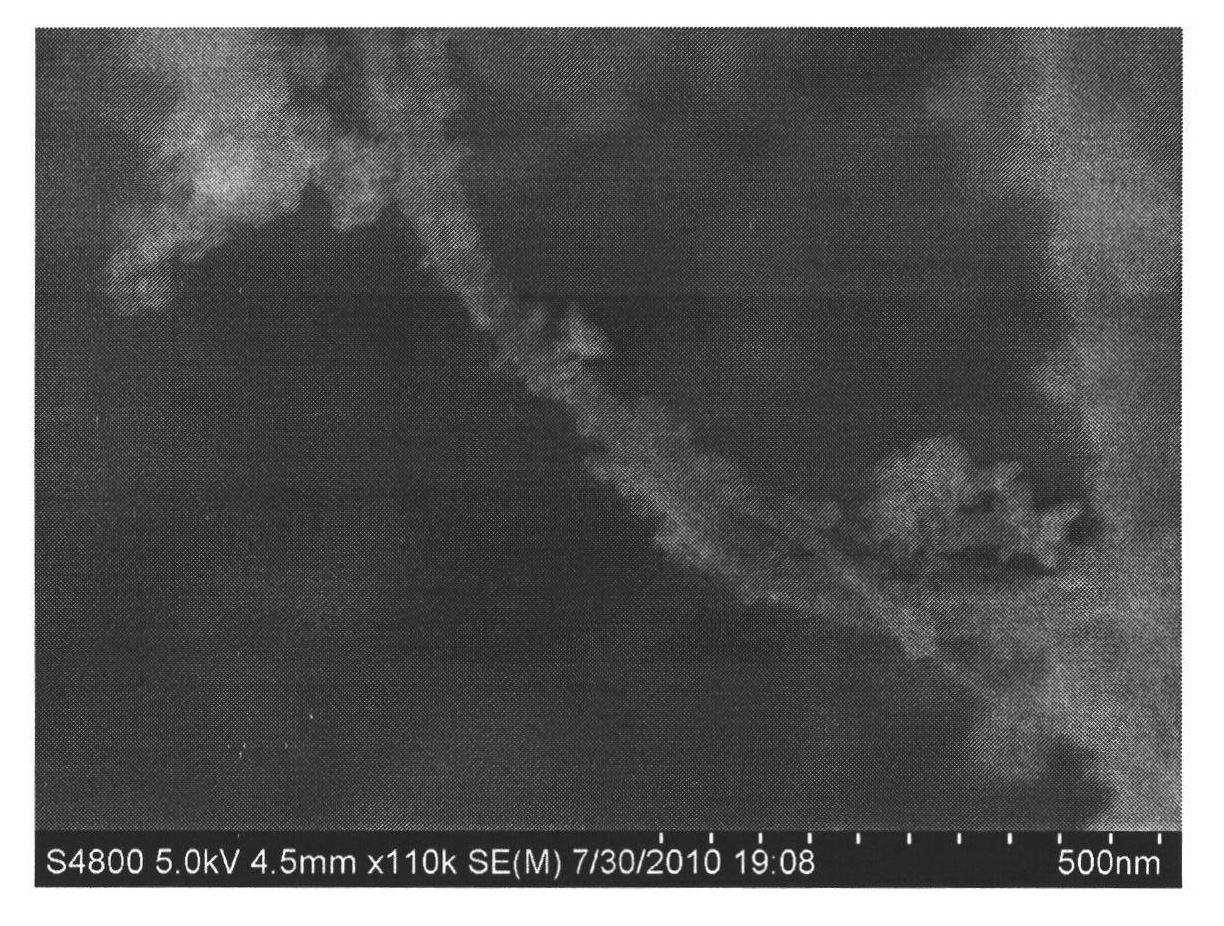

[0035]7 g of carbon nanotubes were added to 500 ml of absolute ethanol and 50 ml of nitric acid, and ultrasonically oscillated for 1 h to obtain a solution A. Add 350ml of tetrabutyl titanate into 700ml of absolute ethanol under the condition of ultrasonic oscillation, and shake for 1 hour to obtain solution B. Add 1 g of manganese acetate to 5 ml of acetic acid and 50 ml of absolute ethanol, shake for 1 h to obtain solution C. Add 0.6g of ammonium metavanadate and 1.2g of oxalic acid into 50ml of absolute ethanol, shake for 1h to obtain D solution. Mix solution C and solution D, slowly add it to solution B, then add it to solution A, shake it for 1-2 hours, put it into the reaction kettle, keep it at 230°C for 2 hours, cool it to room temperature, filter it with Wash with deionized water until neutral, dry and grind to obtain the catalyst. The phase composition of the catalyst see figure 1 , titanium dioxide exists in the a...

Embodiment 2

[0037] Embodiment 2: adopt solvothermal method

[0038] 7 g of carbon nanotubes were added to 500 ml of absolute ethanol and 50 ml of nitric acid, and ultrasonically oscillated for 1 h to obtain a solution A. Add 350ml of tetrabutyl titanate into 700ml of absolute ethanol under the condition of ultrasonic oscillation, and shake for 1 hour to obtain solution B. Add 10 g of manganese acetate to 50 ml of acetic acid and 50 ml of absolute ethanol, shake for 1 h to obtain solution C. Add 6g of ammonium metavanadate and 12g of oxalic acid into 50ml of absolute ethanol, shake for 1h to obtain D solution. Mix solution C and solution D, slowly add it to solution B, then add it to solution A, shake it for 1-2 hours, put it into the reaction kettle, keep it at 230°C for 2 hours, cool it to room temperature, filter it with Wash with deionized water until neutral, dry and grind to obtain the catalyst.

[0039] The obtained catalyst was mixed with 20% bentonite, added a small amount of w...

Embodiment 3

[0040] Embodiment 3: adopt solvothermal method

[0041] 7 g of carbon nanotubes were added to 500 ml of absolute ethanol and 50 ml of nitric acid, and ultrasonically oscillated for 1 h to obtain a solution A. Add 350ml of tetrabutyl titanate into 700ml of absolute ethanol under the condition of ultrasonic oscillation, and shake for 1 hour to obtain solution B. Add 20g of manganese acetate to 100ml of acetic acid and 50ml of absolute ethanol, shake for 1h to obtain C solution. Add 12g of ammonium metavanadate and 24g of oxalic acid into 50ml of absolute ethanol, shake for 1h to obtain D solution. Mix solution C and solution D, slowly add it to solution B, then add it to solution A, shake it for 1-2 hours, put it into the reaction kettle, keep it at 230°C for 2 hours, cool it to room temperature, filter it with Wash with deionized water until neutral, dry and grind to obtain the catalyst.

[0042] The obtained catalyst was mixed with 20% bentonite, added a small amount of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com