Preparation method for micro-order platy silver powder

A flaky silver powder, micron-level technology, applied in the field of preparation of micron-sized flaky silver powder, can solve the problems of not being able to produce particle sizes that meet the requirements, inconsistent technical indicators, and reducing the purity of flaky silver powder, so as to save pollution and High energy consumption, wide reaction temperature range and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

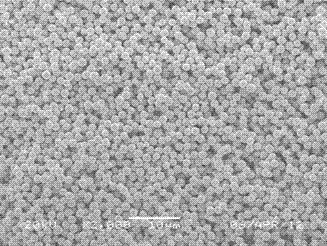

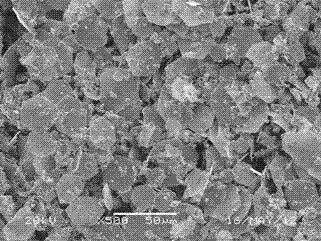

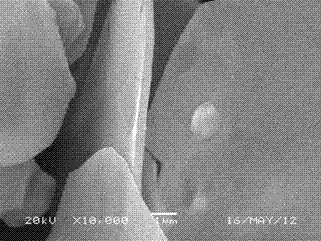

Image

Examples

Embodiment 1

[0025] (1) Preparation of AgNO 3 Aqueous solution: a certain mass of solid AgNO 3 Dissolved in a certain volume of deionized water to prepare AgNO with a mass concentration of 16g / L 3 aqueous solution, and adjust its pH to 3.0 with dilute nitric acid solution;

[0026] (2) Prepare an aqueous solution of reducing agent ascorbic acid: prepare an aqueous solution of ascorbic acid with a mass concentration of 12 g / L;

[0027] (3) Prepare an inducer sulfuric acid aqueous solution with a mass concentration of 180g / L;

[0028] (4) Reduction reaction, liquid-solid separation: 20mL of sulfuric acid aqueous solution with a mass concentration of 180g / L and 200mL of ascorbic acid solution with a mass concentration of 12g / L were mixed into 200mL of silver nitrate solution successively at room temperature 25°C and in a stirring state, and the reaction After 3 minutes, stop the stirring, let stand for 30 minutes, and separate the solid and liquid to obtain a solid product;

[0029] (5) C...

Embodiment 2

[0032] (1) Prepare AgNO with a mass concentration of 40g / L 3 Aqueous solution whose pH is adjusted to 5.0 with dilute nitric acid solution;

[0033] (2) Prepare an aqueous solution of reducing agent ascorbic acid: prepare an aqueous solution of ascorbic acid with a mass concentration of 32 g / L;

[0034] (3) Prepare an inducer sulfuric acid aqueous solution with a mass concentration of 180g / L;

[0035] (4) Reduction reaction, liquid-solid separation: 100mL of sulfuric acid aqueous solution with a mass concentration of 180g / L and 500mL of ascorbic acid solution with a mass concentration of 32g / L were mixed into 500mL of silver nitrate solution successively under stirring at room temperature at 30°C. After 5 minutes, stop the stirring and let stand for 120 minutes; separate the solid and liquid to obtain a solid product;

[0036] (5) Cleaning and drying of the solid product: The solid product obtained in step (4) was washed with deionized water and absolute ethanol until the pH...

Embodiment 3

[0039] (1) Prepare AgNO with a mass concentration of 120g / L 3 Aqueous solution whose pH is adjusted to 3.0 with dilute nitric acid solution;

[0040] (2) Prepare an aqueous solution of reducing agent ascorbic acid: prepare an aqueous solution of ascorbic acid with a mass concentration of 96 g / L;

[0041] (3) Prepare an aqueous solution of inducer sodium sulfate with a mass concentration of 100g / L;

[0042](4) Reduction reaction, liquid-solid separation: 120mL of sodium sulfate aqueous solution with a mass concentration of 100g / L and 400mL of ascorbic acid solution with a mass concentration of 96g / L were mixed into 400mL with a mass concentration of 120g at a room temperature of 35°C and under stirring. / L of silver nitrate solution, after reacting for 3min, stop stirring, and let stand for 80min; solid-liquid separation, to obtain solid product;

[0043] (5) Cleaning and drying of the solid product: The solid product obtained in step (4) was washed with deionized water and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com