Bismuth compounded bismuth oxyiodide photocatalyst containing iodide ionic defects and preparation method of bismuth compounded bismuth oxyiodide photocatalyst

A technology of bismuth oxyiodide and photocatalyst, which is applied in the field of bismuth composite bismuth oxyiodide photocatalyst and its preparation, which can solve the problems of inability to change the transition excitation path of photogenerated electrons, inability to promote the transfer efficiency of photogenerated electrons, and low utilization rate of solar energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

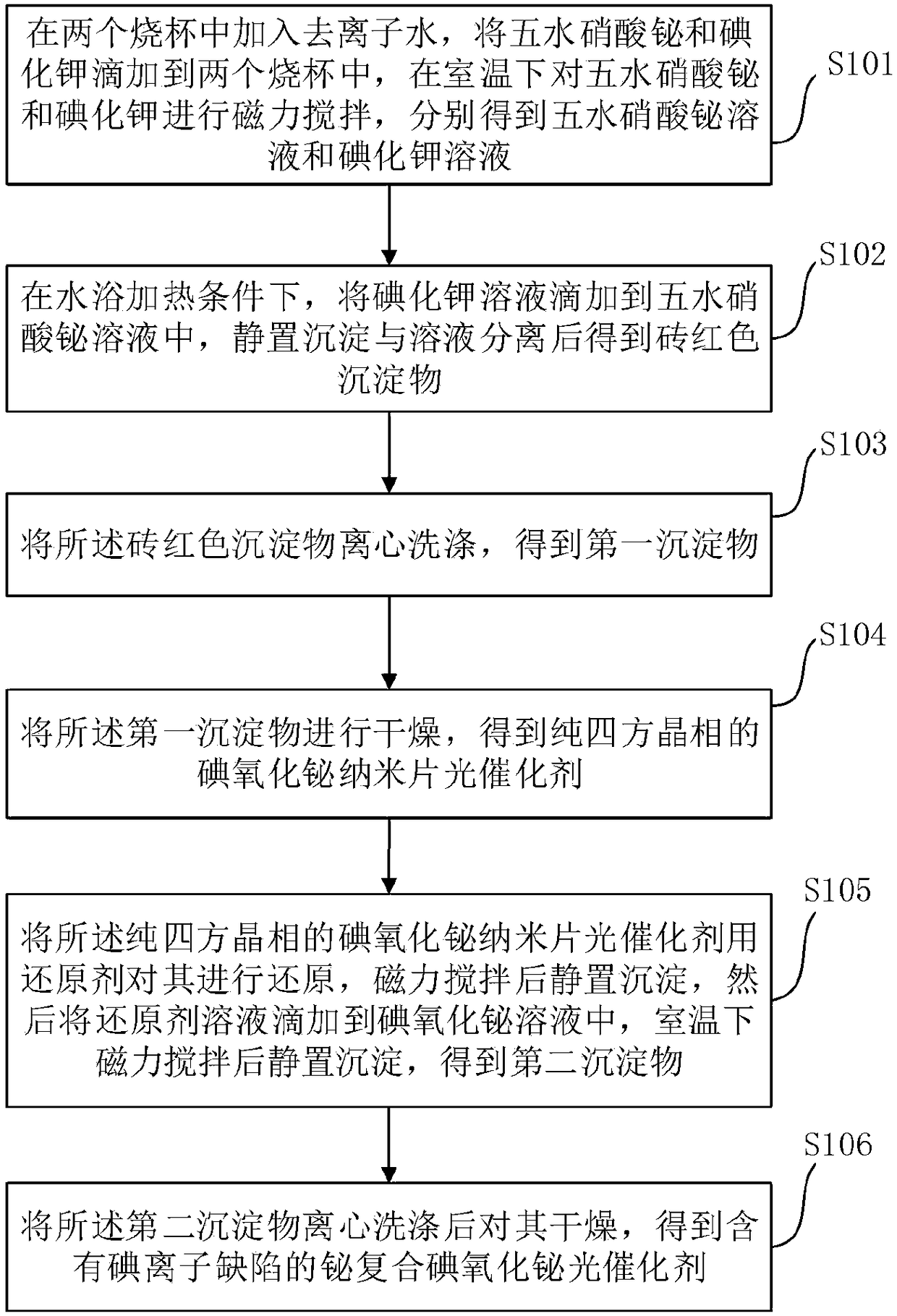

[0042] figure 1 A flow chart of a method for preparing a bismuth composite bismuth oxyiodide photocatalyst containing iodide ion defects shown in the embodiments of the present application, the method comprising:

[0043] S101, add deionized water to both beakers, drop bismuth nitrate pentahydrate and potassium iodide into the two beakers respectively, and magnetically stir bismuth nitrate pentahydrate and potassium iodide at room temperature to obtain bismuth nitrate pentahydrate solutions respectively and potassium iodide solution;

[0044] S102, under the condition of heating in a water bath, the potassium iodide solution is added dropwise to the bismuth nitrate pentahydrate solution, and the brick-red precipitate is obtained after the static precipitation is separated from the solution;

[0045] S103, centrifuging and washing the brick-red precipitate to obtain a first precipitate;

[0046] S104, drying the first precipitate to obtain a pure tetragonal bismuth oxyiodide ...

Embodiment 1

[0077] (1) Add bismuth nitrate pentahydrate and potassium iodide to a 50ml beaker containing 25mL deionized water and a 25ml beaker containing 10ml deionized water respectively, the molar ratio of the two additions is 1:1, and stir magnetically for 30 minutes at room temperature , obtain bismuth nitrate pentahydrate solution and potassium iodide solution respectively;

[0078] (2) Add the potassium iodide solution dropwise to the bismuth nitrate pentahydrate solution under the condition of heating in a water bath at 80°C, react for 2 hours, let the precipitation stand still and separate from the solution to obtain a brick-red precipitate;

[0079] (3) Washing the brick red precipitate with ethanol and deionized water respectively twice before and after each to obtain the first precipitate;

[0080] (4) Drying the first precipitate in an oven at 60° C. to obtain a pure tetragonal bismuth oxyiodide nanosheet photocatalyst.

[0081] The bismuth oxyiodide nanosheet photocatalyst ...

Embodiment 2

[0084] (1) Add bismuth nitrate pentahydrate and potassium iodide to a 50ml beaker containing 25mL deionized water and a 25ml beaker containing 10ml deionized water respectively, the molar ratio of the two additions is 1:1, and stir magnetically for 30 minutes at room temperature , obtain bismuth nitrate pentahydrate solution and potassium iodide solution respectively;

[0085] (2) Add the potassium iodide solution dropwise to the bismuth nitrate pentahydrate solution under the condition of heating in a water bath at 80°C, react for 2 hours, let the precipitation stand still and separate from the solution to obtain a brick-red precipitate;

[0086] (3) Washing the brick red precipitate with ethanol and deionized water respectively twice before and after each to obtain the first precipitate;

[0087] (4) drying the first precipitate in an oven at 60°C to obtain a pure tetragonal bismuth oxyiodide nanosheet photocatalyst;

[0088] (5) Weigh 0.70 gram of pure tetragonal bismuth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com