Method for preparing manganese dioxide catalyst for normal-temperature low-concentration NO catalytic purification with ultrasonic assisted alcohol-water solution method

A catalytic purification, nano-manganese dioxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low preparation efficiency and short catalytic life. , to achieve the effect of simple operation, low cost and shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Among the many preparation methods of manganese oxides, the present invention selects a simple and convenient oxidation-reduction method. By adjusting raw material components and process parameters and introducing ultrasonic treatment, the rapid preparation of manganese oxides can be realized, and the normal temperature and low concentration NO The removal performance has been significantly improved, and the 100% NO removal rate can be maintained for more than 5 hours. The invention provides a method for preparing nano-catalyst manganese dioxide used for catalytic purification of nitrogen monoxide (NO) with low concentration at normal temperature-ultrasound-assisted redox method of alcohol aqueous solution. Specifically, potassium permanganate and alcohol are used as raw materials, and manganese dioxide is obtained after ultrasonic treatment, suction filtration, washing, and drying. In one example, potassium permanganate solution of a certain concentration is added drop...

Embodiment 1

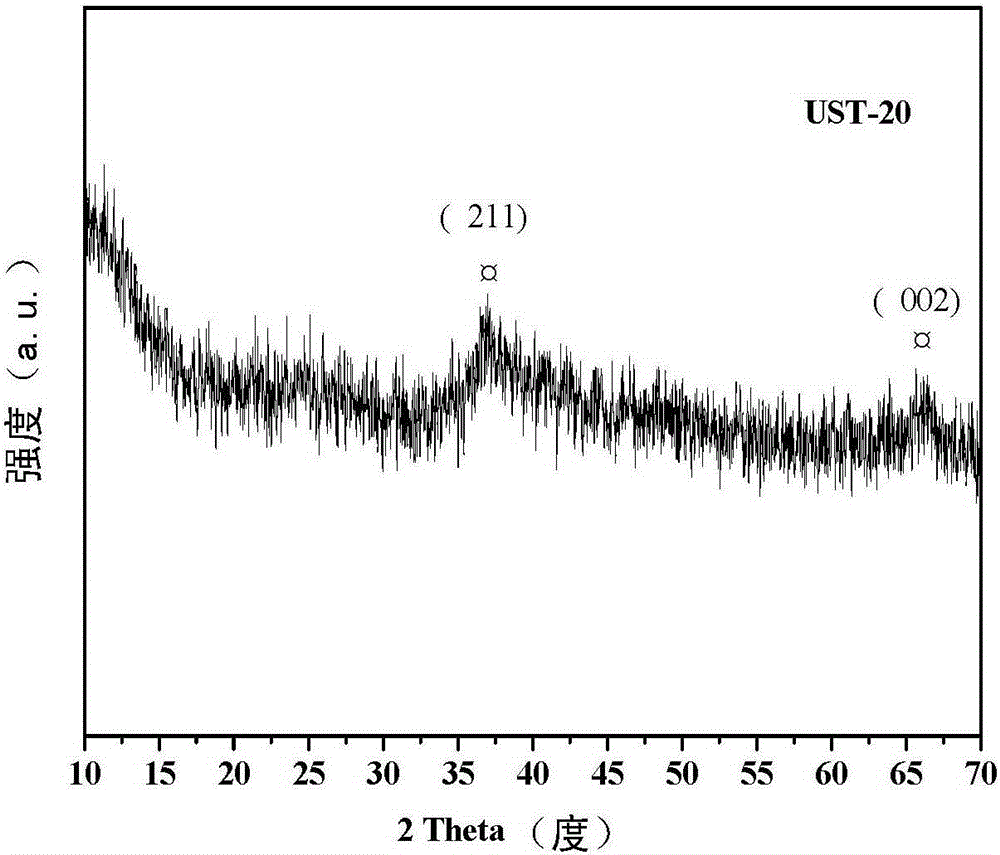

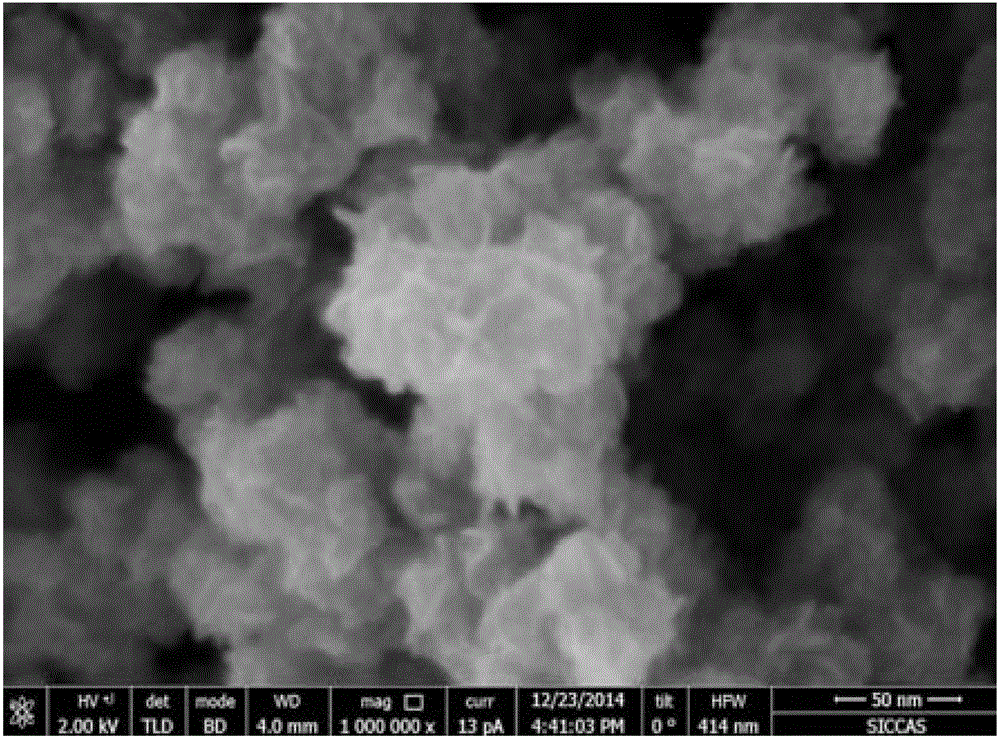

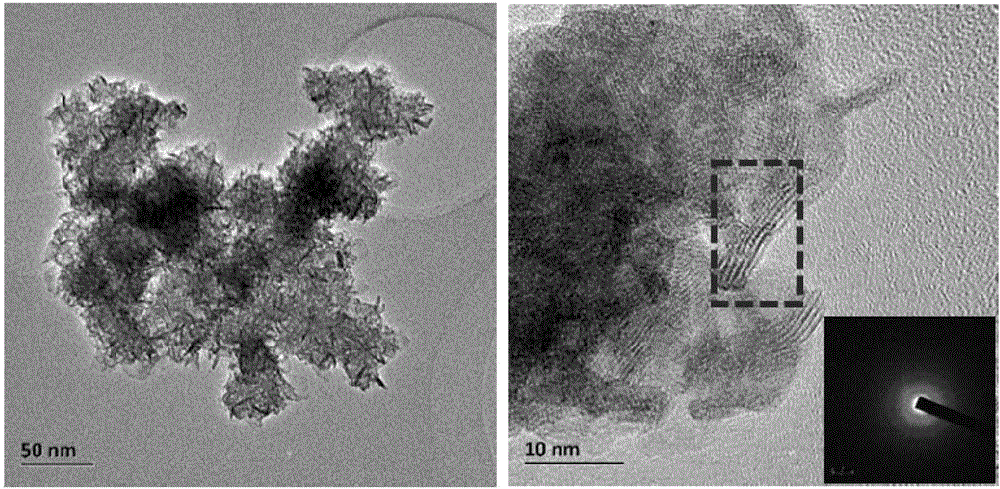

[0041] Weigh 1.58gKMnO 4 Dissolve in 10mlH 2 O, placed in a 40°C water bath and stirred to dissolve. Measure 10ml of ethanol into a jar. Mix KMnO on a magnetic stirrer 4 The solution was added dropwise into ethanol, and after a period of time, it was placed in an ultrasonic reaction cell at 30°C for 20 minutes, filtered and washed with deionized water, and dried in an oven at 80°C for 14 hours. The XRD diffraction pattern of the prepared catalyst is attached figure 1 As shown, it can be seen that the prepared MO is in a weakly crystallized state, with a certain peak shape but not particularly obvious, so it is not possible to completely distinguish its type. Therefore, we calcined the sample at a certain temperature and then used XRD to characterize it. , the peak position and peak shape of the comparison sample are consistent with PDF#44-0141, indicating that the sample is tetragonal MnO 2 . SEM photos are attached figure 2 As shown, it can be seen that the morphology...

Embodiment 2

[0045] Weigh 1.58gKMnO respectively 4 Dissolve in 10mlH 2 O, placed in a 40°C water bath and stirred to dissolve. Measure 10ml of ethanol into a jar. Mix KMnO on a magnetic stirrer 4 The solution was added dropwise into ethanol, and after a period of time, it was put into an ultrasonic reaction cell at 30°C for ultrasonication, and the ultrasonic time was 0 min, 20 min, 40 min, and 60 min, respectively. Then, it was filtered and washed with deionized water, and dried in an oven at 80°C for 14 hours. The NO removal performance curve of the prepared catalyst is shown in the attached Figure 6 As shown, it can be seen that when the ultrasonic time is 20 min and 40 min, the 100% catalytic purification of NO can be maintained for more than 10 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com