Method of treating discharged sewage of circulating water plant through precoated membrane filtration technology

A technical treatment and membrane filtration technology, which is applied in the field of pre-coating membrane filtration technology to treat the sewage discharged from circulating water plants, can solve the problems of large water volume, many interfering impurities, and many technological processes, and achieve stable treatment effect and anti-interference Strong, good anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

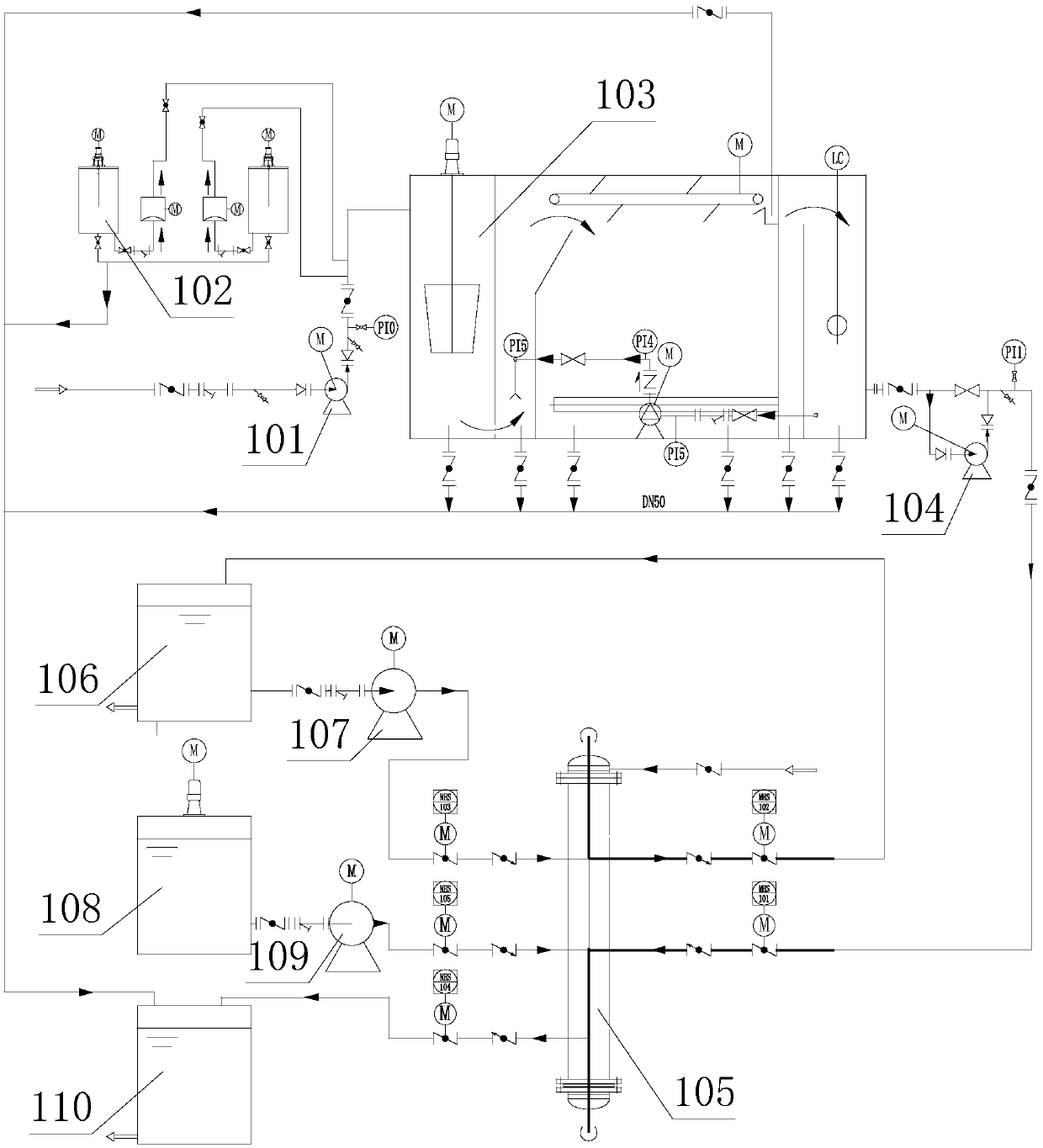

[0030] The waste water in this embodiment refers to the sewage discharged from the circulating water plant.

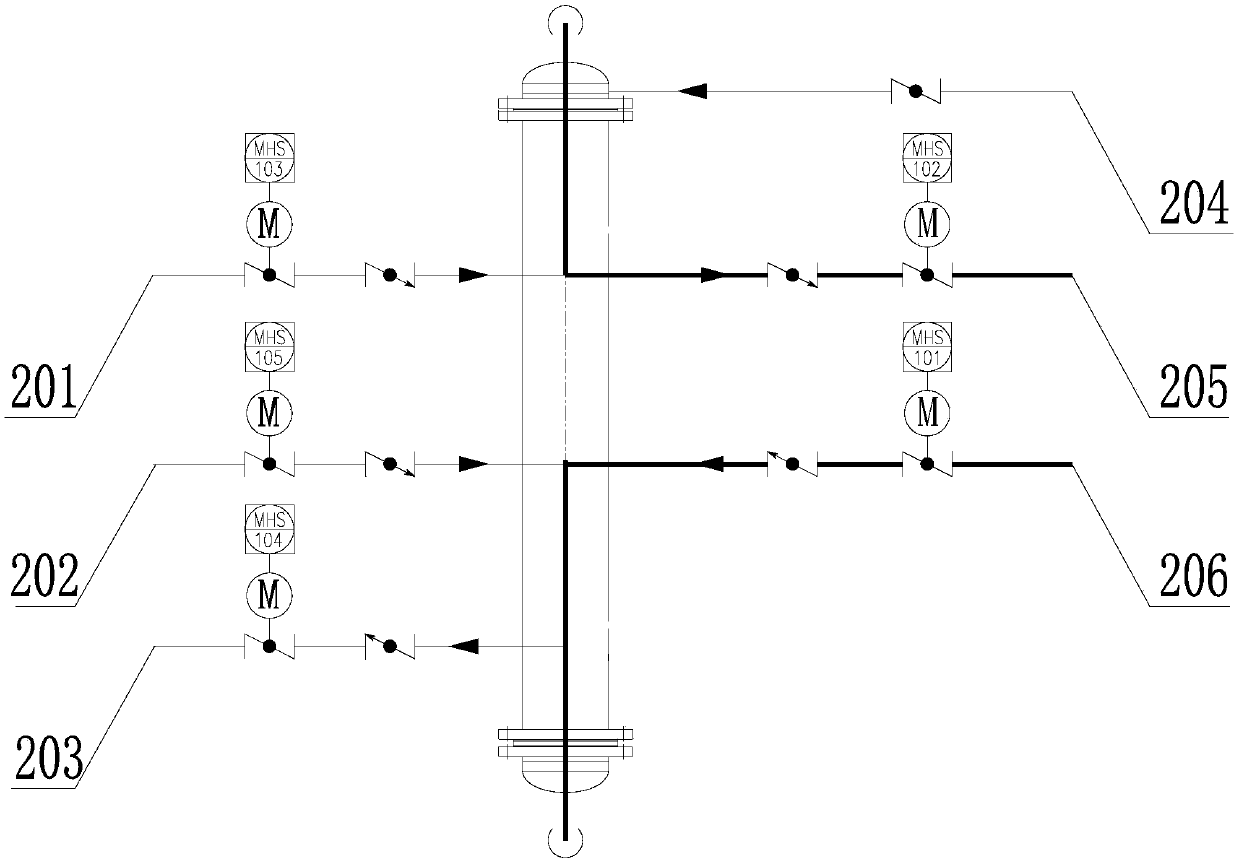

[0031] A method for treating sewage discharged from a circulating water plant by pre-coating membrane filtration technology of the present invention comprises the following steps: 1) Pretreatment of waste water by dosing coagulation air flotation unit; 2) Pre-coating membrane filtration unit The air flotation produced water undergoes advanced treatment, and after treatment, it can be reused or enter the next-level treatment system.

[0032] Further, a kind of pre-coating membrane filtration technology of the present invention treats the method for circulating water plant effluent sewage, described Dosing coagulation air flotation unit refers to the multiphase flow dissolved air flotation process And other equivalent air flotation process units; Step 1) Need to add chemicals such as PAC, PAM chemicals, etc., and flocculate the sewage and the added chemicals to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com