Microfiltration water inlet ultrafine powder activated carbon pretreatment method

A powder activated carbon and pretreatment technology, applied in the field of water treatment, can solve the problem of low removal rate of organic matter in microfiltration, and achieve the effect of increased removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

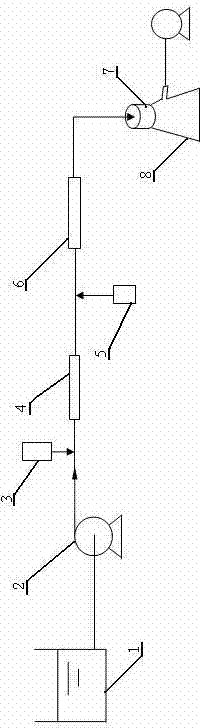

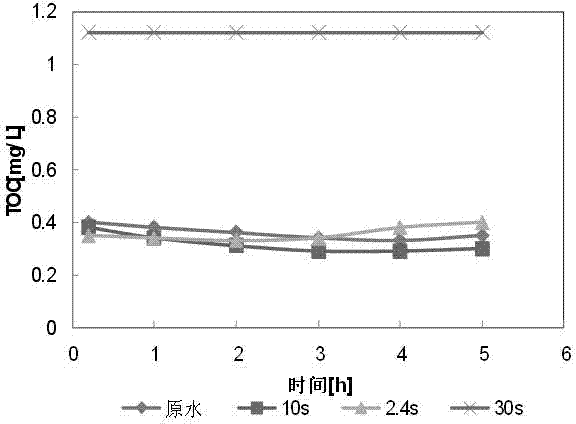

[0022] A flat ceramic membrane with a pore size of 0.2 μm and a diameter of 47 mm (Whatman, Germany) was used for the experiment, and the feed was fed at room temperature (20-25°C). The experimental procedure is as described above. Inlet water is mixed with 1.5 μm ultrafine powdered activated carbon from activated carbon storage tank 3 in tubular reactor 4 through feed pump 2, the mixing time is 30s, 10s and 2.4s, and the addition of ultrafine powdered carbon is 5mg / L, Then add 3.5mg-Al / L flocculant polyaluminum, after mixing with a static mixer, enter the ceramic membrane dead-end filter to obtain product water, analyze the TOC content of raw water and product water, and the results are as follows figure 2 As shown, the best mixing time is 10s, at this time the average TOC is about 3mg / L, and the removal rate is about 73%.

Embodiment 2

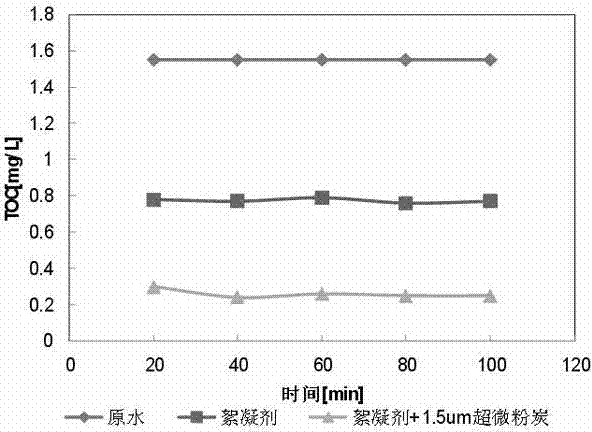

[0024] Such as image 3 As shown, a flat ceramic membrane with a pore size of 0.1 μm and a diameter of 47 mm (Whatman, Germany) was used for the experiment, and the material was fed at room temperature (20-25 ° C). The TOC value of raw water is 1.55mg / L. The experiment was first carried out under the condition that only flocculant was used. The raw water was mixed with 3.5mg-Al / L flocculant polyaluminum through static mixer 6 without adding activated carbon, and then entered into the filter to obtain produced water. The average value of TOC was measured The removal rate of 0.77mg / L is about 50%. Carry out another experiment afterwards, feed water is mixed in tubular reactor through feed pump 2 and the 1.5 μ m ultrafine powder activated carbon from activated carbon storage tank 3, and mixing time is 10s, and the add-on of ultrafine powder carbon is 5mg / L, Then add 3.5mg-Al / L flocculant polyaluminum, after mixing by static mixer 6, enter ceramic membrane dead-end filter, obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com