Method of filtration and backwashing using hollow fibre membrane elements

A technology of backwashing and backwashing water, which is applied in the direction of chemical instruments and methods, membranes, ultrafiltration, etc., and can solve the problem that the removal of impurities is not efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] Other features and advantages of the invention will become apparent from the following description of preferred embodiments of the invention.

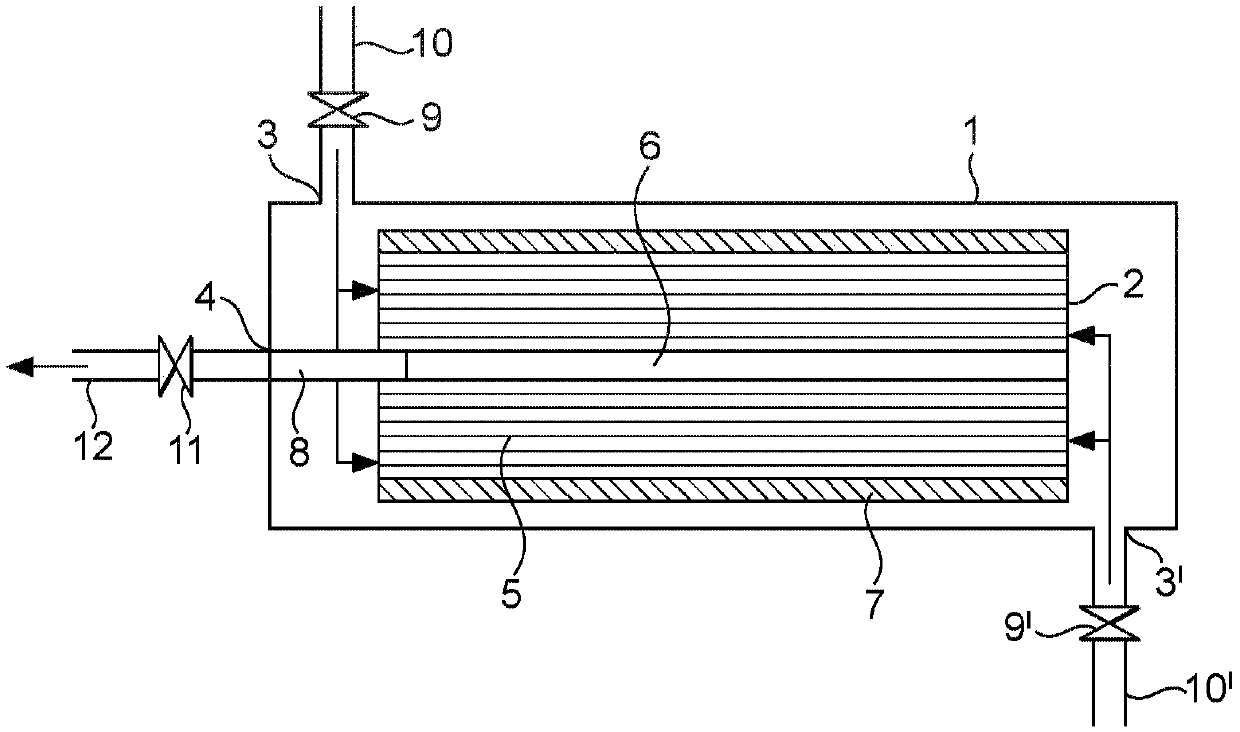

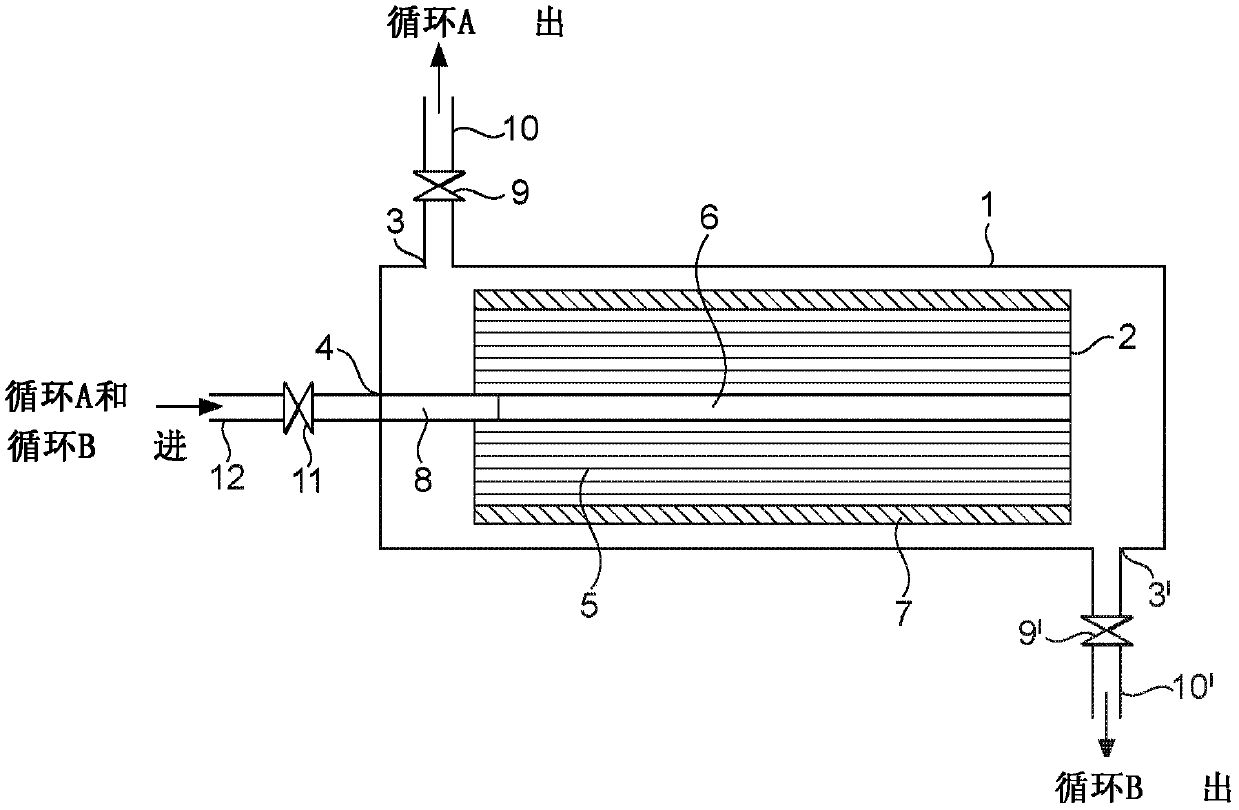

[0043] A filter container may contain a single filter element. Where the filter vessel comprises a single filter element, the first feed port and the second feed port are arranged in the filter vessel at or near the first and second ends of the filter vessel. A single filtrate port may be disposed in the filter vessel at or near one of the first and second ends of the filter vessel. Preferably, the first and second filtrate ports are arranged in the wall of the filter vessel at or near the first and second ends of the filter vessel. Typically, a single filter element is arranged in the filter vessel between the feed port and the filtrate port.

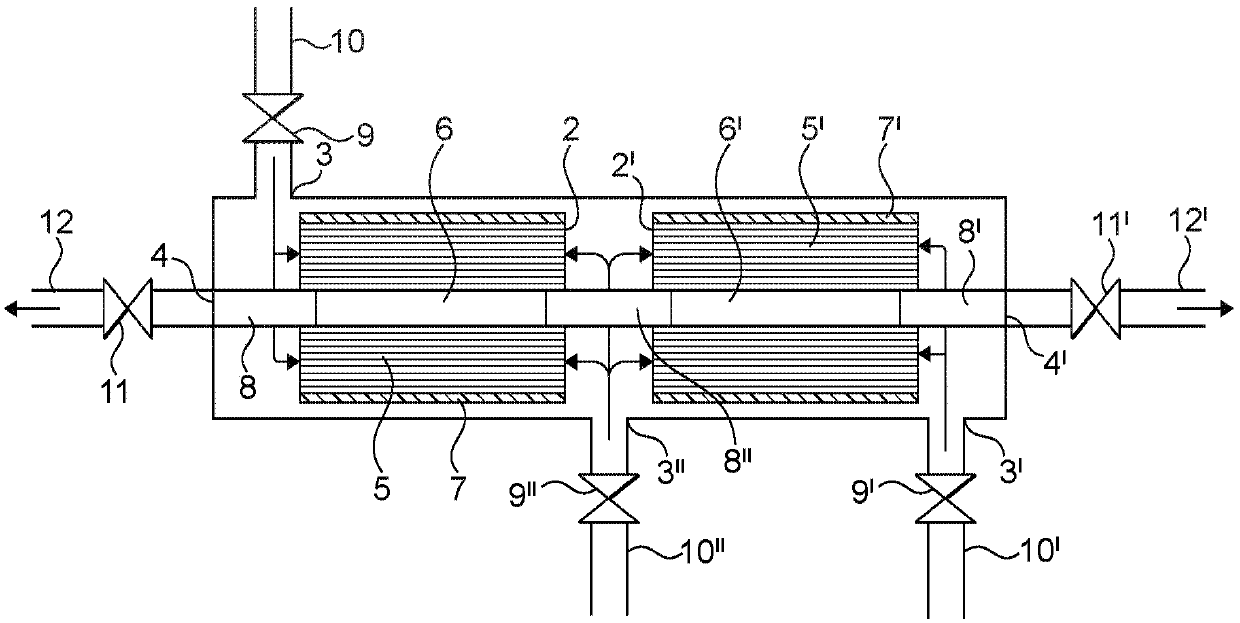

[0044] Preferably, the filter vessel may contain a plurality of filter elements arranged in a row (or series) with spaces or gaps between adjacent filter elements and at the end filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com