Method for removing smelly substances in water

A technology for removing odor substances and water, which is applied in the field of removing odor substances in water to achieve the effects of controlling membrane fouling, reducing membrane fouling, and eliminating odor substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

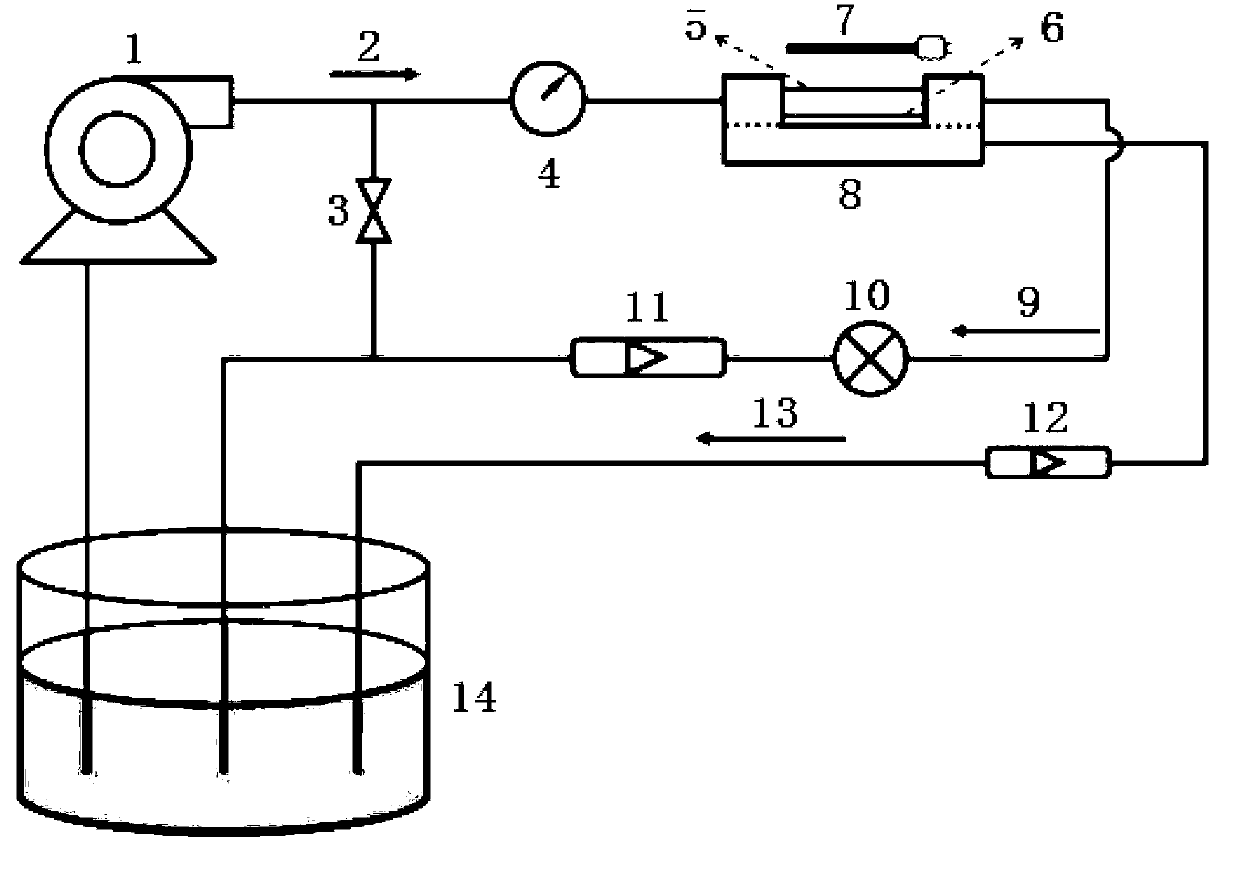

Image

Examples

Embodiment 1

[0029] Step 1, configure the water sample containing odorant to be treated, wherein the concentrations of geosmin, 2-methylisobutyritol, β-ring citral, β-ionone, and dimethyl trisulfide are respectively 500ng / L, 500ng / L, 2000ng / L, 1500ng / L and 2500ng / L. The membrane used is polyvinylidene fluoride-polyethylene glycol-titanium dioxide (PVDF-PEG / TiO 2 ) film, the specific preparation process and corresponding conditions are as follows: Accurately weigh 12wt.% and 0.5wt.% of polyvinylidene fluoride powder and visible light-responsive titanium dioxide nanoparticles, respectively; add polyethylene glycol 3wt.%, dissolve in In the N,N-dimethylacetamide solvent, after being configured as a casting solution, place it in a constant temperature water bath, stir continuously for 24 hours under the condition that the temperature of the water bath is 40°C, and then let it stand at 40°C for 24h, so that It matures and degasses. Using a glass plate as a carrier, a layer of liquid film was...

Embodiment 2

[0032] Step 1, configure the water sample containing odorant to be treated, wherein the concentrations of geosmin, 2-methylisobutyritol, β-ring citral, β-ionone, and dimethyl trisulfide are respectively 500ng / L, 500ng / L, 2000ng / L, 1500ng / L and 2500ng / L. The membrane used is polyvinylidene fluoride-lithium chloride-titanium dioxide (PVDF-LiCl / TiO 2 ) film, the specific preparation process and corresponding conditions are as follows: Accurately weigh 12wt.% and 0.5wt.% of polyvinylidene fluoride powder and ultraviolet light-responsive titanium dioxide nanoparticles, respectively; add 0.8wt.% of lithium chloride to dissolve In N,N-dimethylacetamide solvent, configure the casting solution and place it in a constant temperature water bath, stir continuously at a water bath temperature of 40°C for 24h, and then stand at 40°C for 24h to make It matures and degasses. Using a glass plate as a carrier, a layer of liquid film was scraped on a flat film scraper at a speed of 1.2 m / min,...

Embodiment 3

[0035] Step 1, configure the water sample containing odorant to be treated, wherein the concentrations of geosmin, 2-methylisobutyritol, β-ring citral, β-ionone, and dimethyl trisulfide are respectively 500ng / L, 500ng / L, 2000ng / L, 1500ng / L and 2500ng / L. The membrane used is polyvinylidene fluoride-lithium chloride-titanium dioxide (PVDF-LiCl / TiO 2 ) film, the specific preparation process and corresponding conditions are as follows: Accurately weigh 12wt.% and 0.5wt.% of polyvinylidene fluoride powder and visible light-responsive titanium dioxide nanoparticles, respectively; add 0.8wt.% lithium chloride, dissolve in In N,N-dimethylacetamide solvent, configure the casting solution and place it in a constant temperature water bath, stir continuously for 24 hours at a water bath temperature of 40°C, and then stand at 40°C for 24 hours to allow it to mature defoaming. Using a glass plate as a carrier, a layer of liquid film was scraped on a flat film scraper at a speed of 1.2 m / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com