Intermittent spiral cross-flow membrane filtering device and method thereof

A cross-flow membrane and spiral technology, applied in the field of membrane separation methods, can solve problems such as difficult to deal with pollution, and achieve the effect of improving the cross-flow water flow distance, easy automatic control, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further specifically described in detail below with reference to specific examples, but the embodiments of the present invention are not limited thereto. For process parameters not specifically noted, reference may be made to conventional techniques.

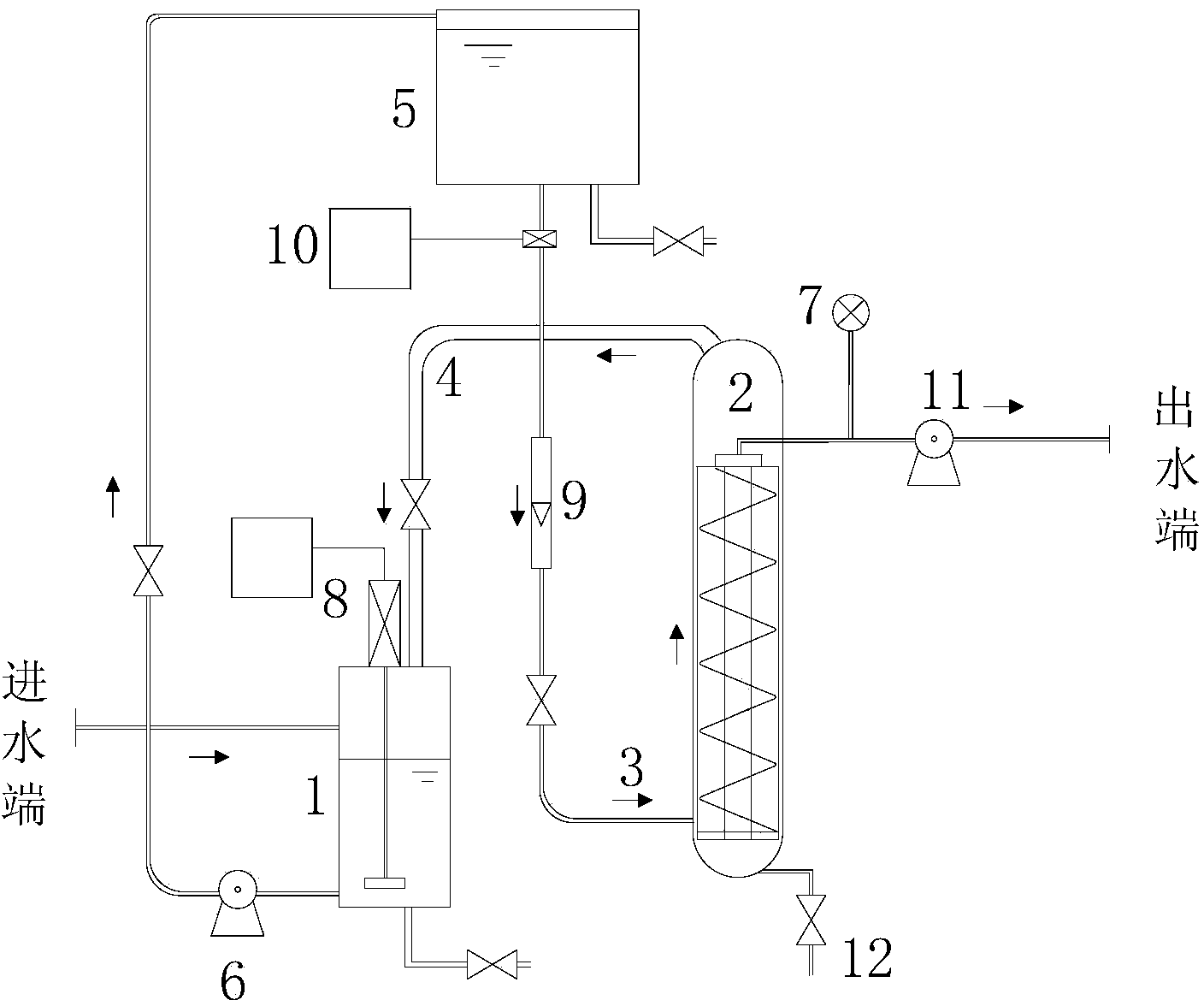

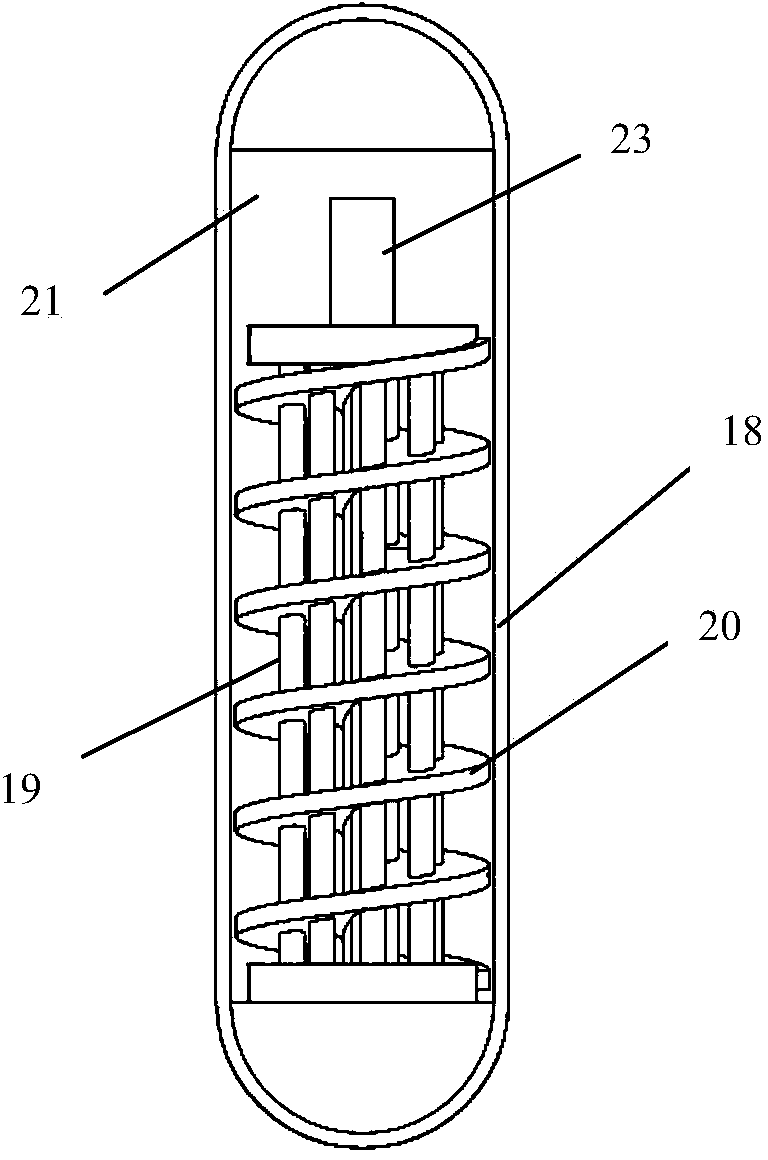

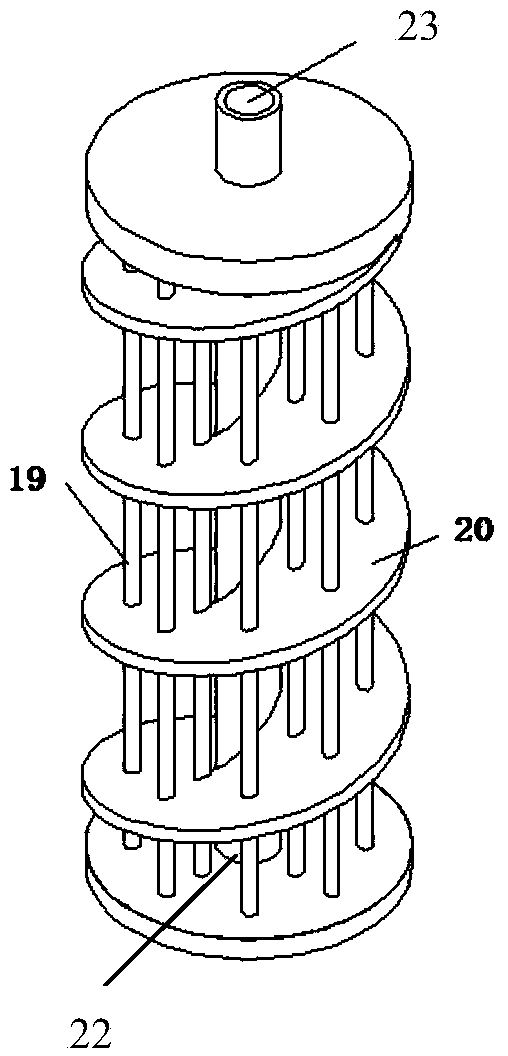

[0030] An intermittent spiral cross-flow membrane filtration device, comprising a membrane module 2 and a water circulation system. The membrane module 2 includes an upright housing 18, a hollow fiber external pressure membrane 19 and a spiral baffle 20. The housing is arranged close to its inner wall. There is a spiral baffle 20, the gap between the spiral baffle and the inner wall of the shell is 2mm; there is a reserved water storage area 21 above the spiral baffle, and a support tube 22 is provided in the middle of the spiral baffle 20. A spiral channel surrounding the support tube 22 is formed between the shells 18; the hollow fiber outer pressure film 19 penetrates the spiral baffle 20 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com