Sewing machine with self-cleaning oil way

A sewing machine and self-cleaning technology, which is applied in the field of sewing machines, can solve the problems of time-consuming oil replacement, oil sludge, oil filter clogging, etc., and achieve the effect of improving the lubrication effect, improving the effect, and efficient oil filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

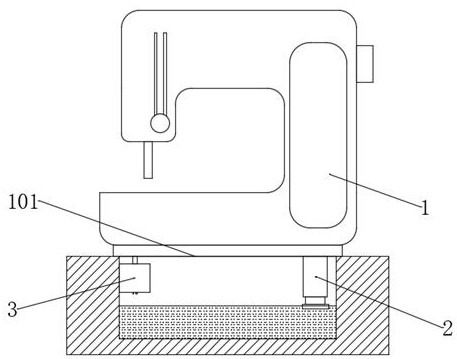

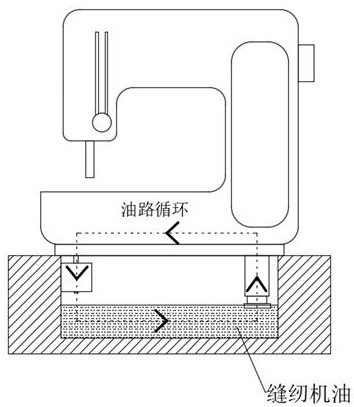

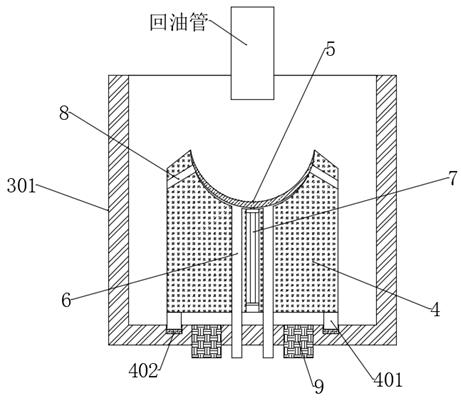

[0047] see Figure 1-10 , an oil circuit self-cleaning sewing machine, including a sewing machine body 1, please refer to figure 1 , 2 , 3. The sewing machine body 1 includes an oil pan 101 at the bottom, and the oil pan 101 is filled with sewing machine oil. There is also an oil return pipe connected to the bottom, please refer to Figure 8 , the oil absorber 2 comprises an outer suction pipe 201 and an inner suction pipe 202, the outer suction pipe 201 is slidingly connected with the inner suction pipe 202, and the lower end of the outer suction pipe 201 is connected with an oil filter head 203 whose density is lower than that of sewing machine oil, because the density of the oil filter head 203 is lower than that of sewing machine oil density, so the inner suction pipe 202 can shrink or elongate following the oil level, so as to cooperate with the cleaning work of the self-cleaning oil filter 3, and also ensure that there is always oil in the oil circuit, avoiding the occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com