Method and production device for preparing graphene micro-plate pre-dispersion master batch

A technology of graphene microchips and production equipment, applied in the field of rubber processing technology, can solve the problems of shortened drying time, poor graphene dispersion, weak interface effect, easy aging of masterbatch, etc., to shorten drying time, save baking rubber and plastic Refining energy consumption, avoiding the effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

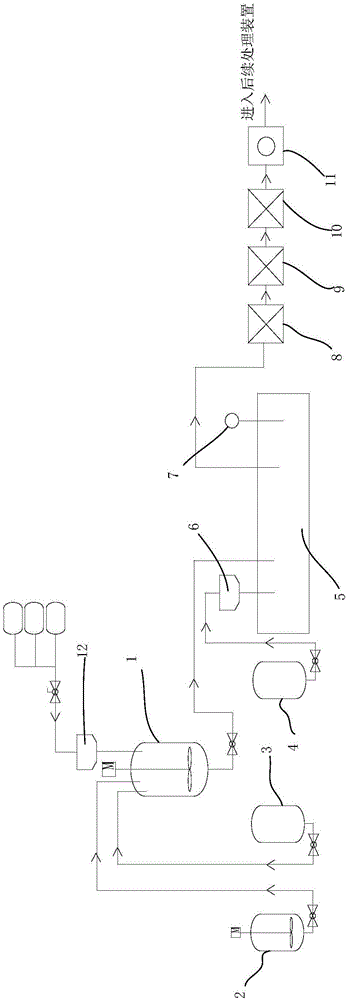

Image

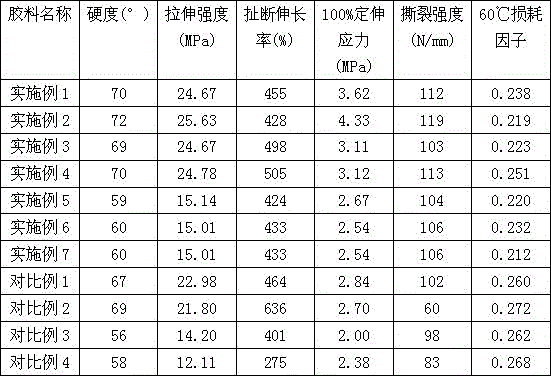

Examples

Embodiment 1

[0023] (1) Preparation of graphene microplatelet dispersion

[0024] Get 600L of water and 6kg of graphene microflakes and add them to the graphene stirring tank 2, stir and disperse at a high speed of 2500rpm at room temperature for 5 hours, and prepare an aqueous dispersion of graphene microflakes with a mass fraction of 1%.

[0025] (2) Mixing and coagulation of graphene microplatelet dispersion / natural rubber latex

[0026] The graphene microsheet aqueous dispersion prepared in the graphene stirring tank 2 is transported in the mixing kettle 1 by pipeline, and the latex in the latex tank 3 is delivered in the mixing kettle simultaneously, and the liquid flow is controlled so that the 1000kg dry glue content is 60% natural rubber latex is added in the high-speed mixer at the same time, and the stirring speed is 400rpm, and the stirring time is 40min to prepare the mixed material; the mixed material is delivered to the settling tank 5; CaCl 2 solution, CaCl 2 The solution...

Embodiment 2

[0034] (1) Preparation of graphene microplatelet dispersion

[0035] Get 600L of water, 1Kg sodium dodecylbenzene sulfonate and join in the graphene stirring tank 2, stir to obtain an aqueous solution; then 30Kg graphene microchips are added to the above aqueous solution, and 3000rpm high-speed stirring disperses at normal temperature for 3 hours, An aqueous dispersion of graphene microsheets with a mass fraction of 5% was prepared.

[0036] (2) Mixing and coagulation of graphene microplatelet dispersion / natural rubber latex

[0037] The graphene microsheet water dispersion prepared in the graphene stirring tank 2 is delivered to the mixing kettle 1 through the pipeline, and the latex in the latex tank 3 is delivered to the mixing kettle 1 at the same time, and the liquid flow is controlled to make the 3000kg dry rubber content 60% natural rubber latex is added in the high-speed mixer simultaneously, and stirring speed is 800rpm, and stirring time is 20min, makes mixed material...

Embodiment 3

[0045] (1) Preparation of graphene microplatelet dispersion

[0046] Take 600L of water and 2Kg sodium dodecylbenzene sulfonate and add them to the graphene stirring tank, stir evenly to obtain an aqueous solution; then add 240Kg graphene microchips to the above aqueous solution, stir and disperse at a high speed of 3000rpm at room temperature for 5 hours, and prepare Aqueous dispersion of graphene microsheets with a mass fraction of 40%.

[0047] (2) Mixing and coagulation of graphene microplatelet dispersion / natural rubber latex

[0048] Graphene microsheet aqueous dispersion prepared in the graphene stirring tank is transported in the mixing kettle by pipeline, and the latex in the latex tank is delivered to the mixing kettle kind simultaneously, and the liquid flow is controlled so that the 1000kg dry glue content is 60% The natural rubber latex is added to the high-speed mixer at the same time, the stirring speed is 600rpm, and the stirring time is 40min to prepare the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com