A charged electromagnetic hydrophobic material and its preparation method and application

A hydrophobic material and electromagnetic technology, applied in the direction of solid separation, flotation, etc., can solve the problems of high-efficiency recovery of useful minerals, low concentrate grade, fine particles in flotation products, etc., and achieve strong chemical adsorption and physical adsorption Ability, efficient enrichment and separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

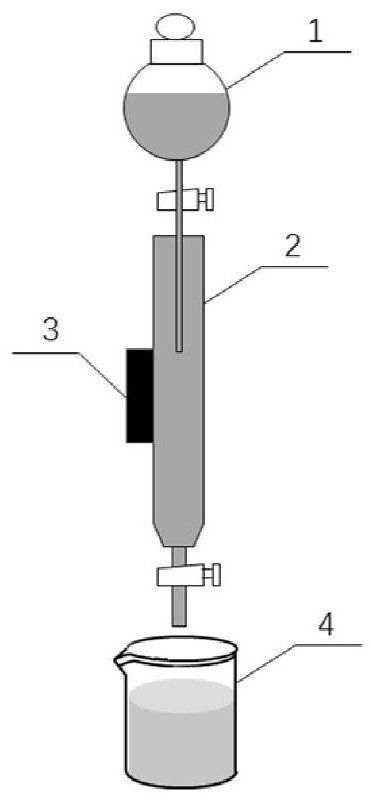

Method used

Image

Examples

Embodiment 1

[0045] Preparation of the modified magnetic carrier: prepare a solution of benzylhydroxamic acid with a concentration of 0.01mol / L and a solution of lead nitrate with a concentration of 0.02mol / L. Take 20mL each and mix in a beaker (adjust the solution pH=9.5), add 5g of magnetite with a particle size ranging from 400 mesh to 600 mesh, and stir for 30 minutes at a speed of 200r / min by a mechanical stirrer to make the magnetite The ore is in full contact with the lead metal complex of benzohydroxamic acid. The modified magnetite is filtered and dried in a vacuum oven to obtain the modified magnetic carrier.

[0046] Configuration of sodium oleate solution: Weigh 0.2436g sodium oleate in a beaker, add a little deionized water, heat to completely dissolve sodium oleate, transfer the solution to a 100mL volumetric flask, cool to room temperature, and then settle to volume to obtain a concentration of 8×10 -3 mol / L sodium oleate solution for use.

[0047] The scheelite pure mine...

Embodiment 2

[0051] Preparation of the modified magnetic carrier: prepare a solution of benzylhydroxamic acid with a concentration of 0.01mol / L and a solution of lead nitrate with a concentration of 0.02mol / L. Take 20mL each and mix in a beaker (adjust the pH=10 of the solution), add 5g of magnetite with a particle size ranging from 400 mesh to 600 mesh, and stir for 10 minutes at a speed of 200r / min by a mechanical stirrer to make the magnetite The ore is in full contact with the lead metal complex of benzohydroxamic acid. The modified magnetite is filtered and dried in a vacuum oven to obtain the modified magnetic carrier.

[0052] Configuration of sodium oleate solution: Weigh 0.2436g sodium oleate in a beaker, add a little deionized water, heat to completely dissolve sodium oleate, transfer the solution to a 100mL volumetric flask, cool to room temperature, and then settle to volume to obtain a concentration of 8×10 -3 mol / L sodium oleate solution for use.

Embodiment 3

[0057] Preparation of the modified magnetic carrier: prepare a solution of benzylhydroxamic acid with a concentration of 0.01mol / L and a solution of calcium chloride with a concentration of 0.02mol / L. Take 20mL each and mix in a beaker (adjust the solution pH=9.5), add 5g of magnetite with a particle size ranging from 400 mesh to 600 mesh, and stir for 30 minutes at a speed of 200r / min by a mechanical stirrer to make the magnetite The ore and the calcium metal complex of benzohydroxamic acid fully contact and react. The modified magnetite is filtered and dried in a vacuum oven to obtain the modified magnetic carrier.

[0058] Configuration of sodium oleate solution: Weigh 0.2436g sodium oleate in a beaker, add a little deionized water, heat to completely dissolve sodium oleate, transfer the solution to a 100mL volumetric flask, cool to room temperature, and then settle to volume to obtain a concentration of 8×10 -3 mol / L sodium oleate solution for use.

[0059] The scheelit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com