Labyrinth type cyclone dedusting device and dedusting method

A dust removal device, labyrinth technology, applied in the field of labyrinth cyclone dust removal device, can solve problems such as ultra-low emission standards, complex combined dust removal system, and difficult transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

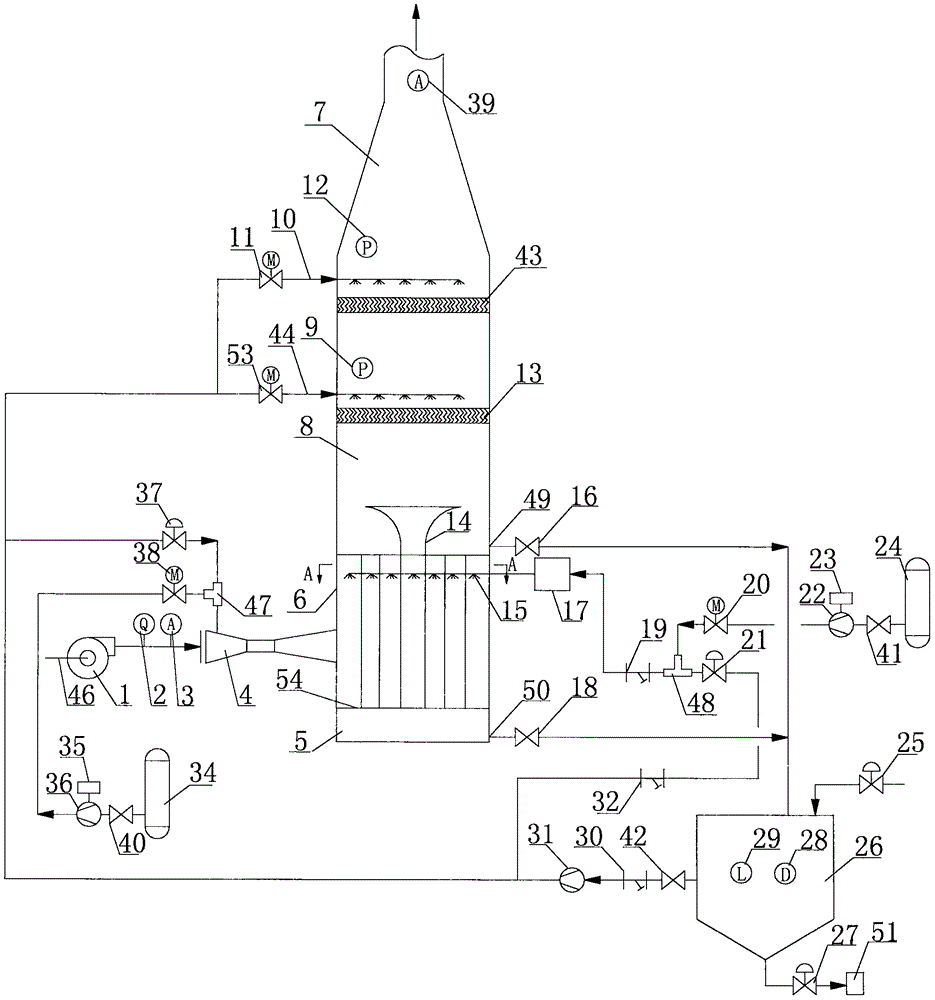

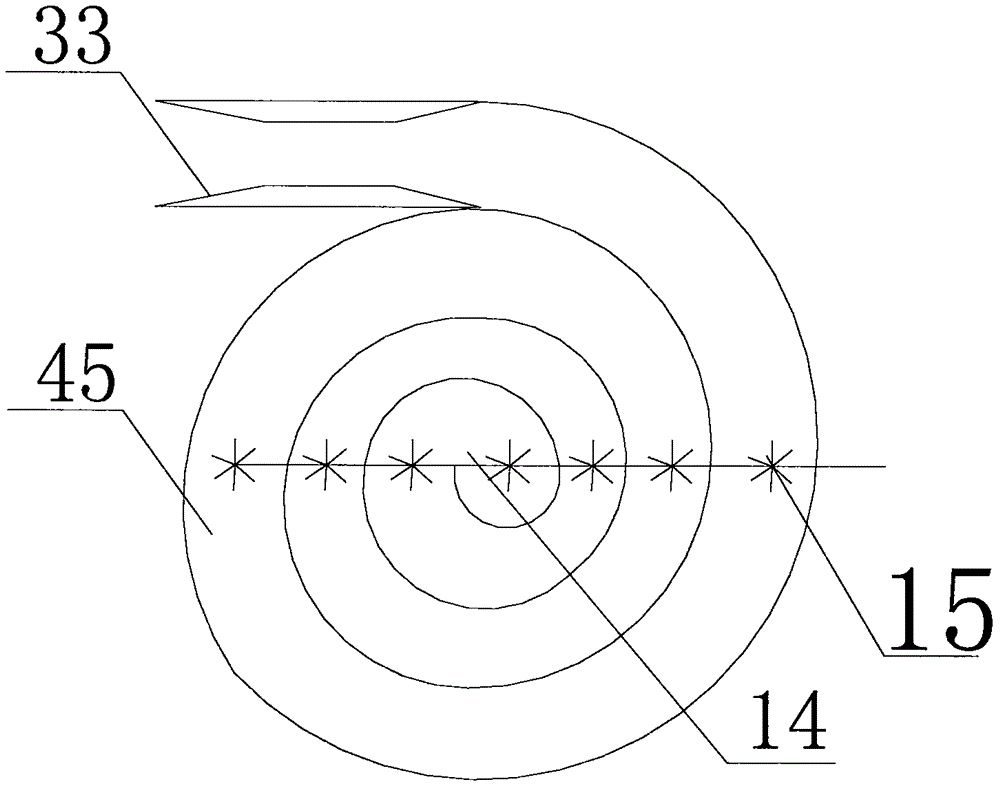

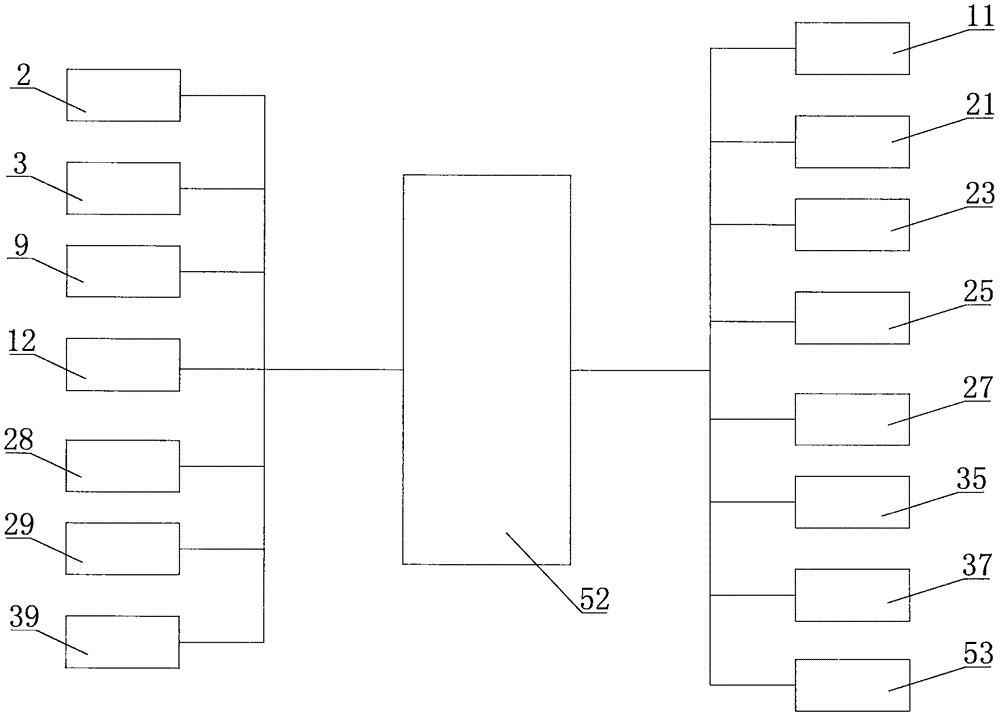

[0039]A kind of labyrinth cyclone dust removal device, this dust removal device includes mechanical part and control part, a, mechanical part includes dust removal device, induced draft fan 1, surfactant storage tank 24, circulating water pool 26 and foam storage tank 34, dust removal device includes The shell 6, the inside of the shell 6 is provided with a chimney 7, an upper flushing pipe 10, an upper mist eliminator 43, a lower flushing pipe 44, a lower mist eliminator 13, a settling mist removal tower 8, a labyrinth rotary flow device and gray water chamber 5, the labyrinth cyclone device includes a throat pipe 33, a spiral spiral housing 45 connected to the throat pipe 33 and an outlet diffuser located in the middle of the top of the spiral spiral housing. Pipe 14, the outlet diffuser pipe 14 is arranged in the inside of the settling demist tower 8; the bottom of the spiral spiral housing 45 is connected to the gray water chamber 5 through the orifice 54; the throat pipe 3...

Embodiment 2

[0049] A kind of labyrinth cyclone dust removal device, this dust removal device includes mechanical part and control part, a, mechanical part includes dust removal device, induced draft fan 1, surfactant storage tank 24, circulating water pool 26 and foam storage tank 34, dust removal device includes The shell 6, the inside of the shell 6 is provided with a chimney 7, an upper flushing pipe 10, an upper mist eliminator 43, a lower flushing pipe 44, a lower mist eliminator 13, a settling mist removal tower 8, a labyrinth rotary flow device and gray water chamber 5, the labyrinth cyclone device includes a throat pipe 33, a spiral spiral housing 45 connected to the throat pipe 33 and an outlet diffuser located in the middle of the top of the spiral spiral housing. Pipe 14, the outlet diffuser pipe 14 is arranged in the inside of the settling demist tower 8; the bottom of the spiral spiral housing 45 is connected to the gray water chamber 5 through the orifice 54; the throat pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com