Halogen-free fire-retardant polyphenyl ether compound and method for preparing same

A technology of compound and polyphenylene ether, which is applied in the field of high toughness, environment-friendly flame retardant polyphenylene ether compound and its preparation, high flow, halogen-free flame retardant polyphenylene ether compound and its preparation field, can solve the lack of fluidity , Flame retardant performance decline and other problems, to achieve the effect of preventing dust, improving fluidity and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

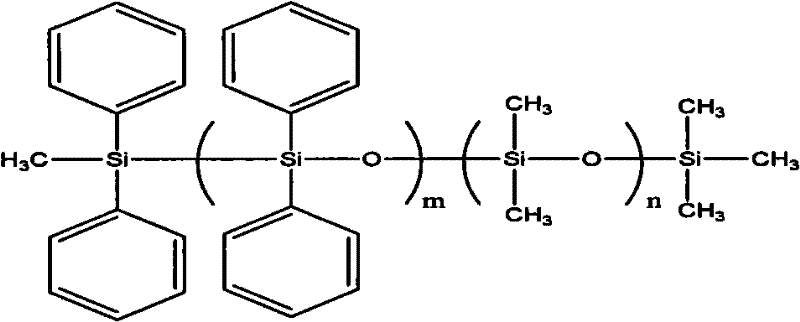

Image

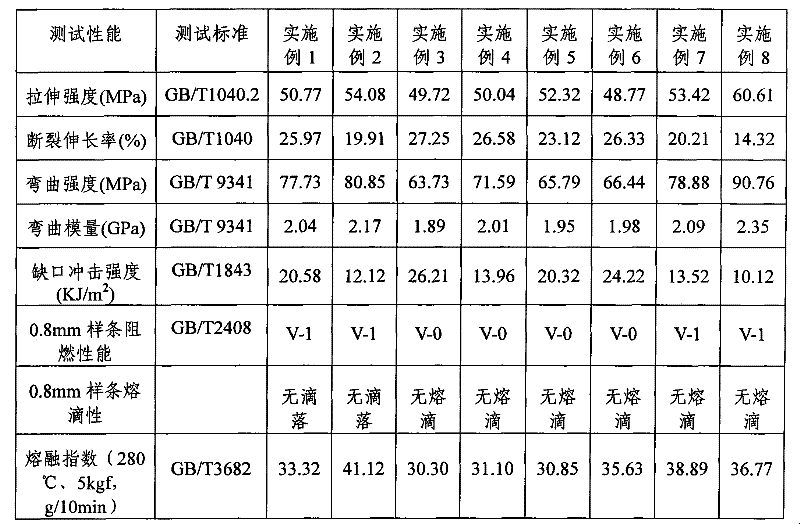

Examples

Embodiment 1

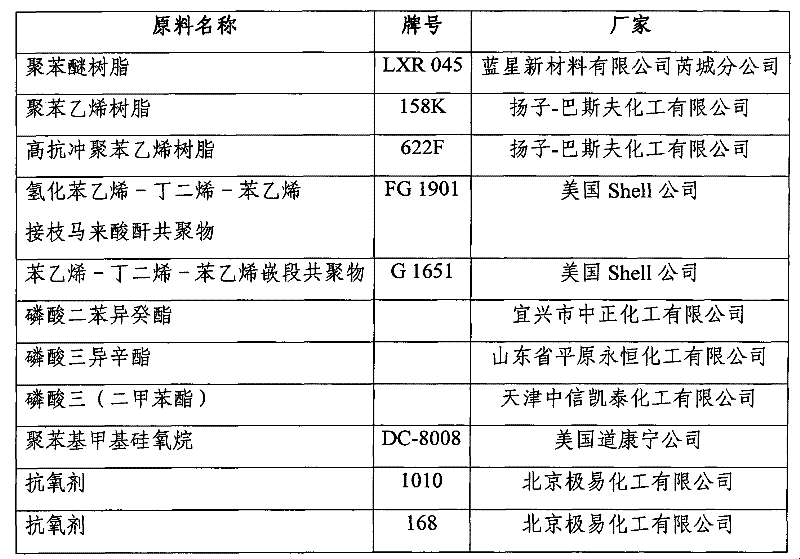

[0027] Take polyphenylene ether resin, polystyrene resin, flame retardant, toughening agent, antioxidant, and blend all raw materials according to the following composition and mass percentage:

[0028] 70 parts by weight of polyphenylene ether

[0029] 10 parts by weight of polystyrene

[0030] 10 parts by weight of diphenylisodecyl phosphate

[0031] 5 parts by weight of polyphenylmethylsiloxane

[0032]SEBS 20 parts by weight

[0033] Antioxidant 1010 0.2 parts by weight

[0034] Antioxidant 168 0.2 parts by weight

[0035] Put all the above-mentioned raw materials into the mixer and mix them evenly, and then extrude and granulate through the twin-screw extruder. , 278°C, 275°C, 272°C, 270°C, 268°C, 270°C, 272°C, the screw speed is 200-240r / min. After the material is extruded, it is water-cooled, pelletized, dried, and then injection-molded to obtain a test sample. The injection molding temperature is 260-280°C, and the injection molding pressure is 60-80MPa. The me...

Embodiment 2

[0037] Take polyphenylene ether resin, polystyrene resin, flame retardant, toughening agent, antioxidant, and blend all raw materials according to the following composition and mass percentage:

[0038] 67 parts by weight of polyphenylene ether

[0039] 20 parts by weight of polystyrene

[0040] 10 parts by weight of diphenylisodecyl phosphate

[0041] 5 parts by weight of polyphenylmethylsiloxane

[0042] SEBS 13 parts by weight

[0043] Antioxidant 1010 0.2 parts by weight

[0044] Antioxidant 168 0.2 parts by weight

[0045] Put all the above-mentioned raw materials into the mixer and mix them evenly, and then extrude and granulate through the twin-screw extruder. , 278°C, 275°C, 272°C, 270°C, 268°C, 270°C, 272°C, the screw speed is 200-240r / min. After the material is extruded, it is water-cooled, pelletized, dried, and then injection-molded to obtain a test sample. The injection temperature is 260-280°C, and the injection pressure is 60-80MPa. The mechanical proper...

Embodiment 3

[0047] Take polyphenylene ether resin, polystyrene resin, flame retardant, toughening agent, antioxidant, and blend all raw materials according to the following composition and mass percentage:

[0048] 72 parts by weight of polyphenylene ether

[0049] Polystyrene 18 parts by weight

[0050] 10 parts by weight of diphenylisodecyl phosphate

[0051] 5 parts by weight of polyphenylmethylsiloxane

[0052] SEBS-g-MAH 10 parts by weight

[0053] Antioxidant 1010 0.2 parts by weight

[0054] Antioxidant 168 0.2 parts by weight

[0055] Put all the above-mentioned raw materials into the mixer and mix them evenly, and then extrude and granulate through the twin-screw extruder. , 278°C, 275°C, 272°C, 270°C, 268°C, 270°C, 272°C, the screw speed is 200-240r / min. After the material is extruded, it is water-cooled, pelletized, dried, and then injection-molded to obtain a test sample. The injection temperature is 270-300°C, and the injection pressure is 70-100MPa. The mechanical pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com