Rough surface polymer composite material, nano-carbon material, preparation method and application

A technology of composite materials and rough surfaces, applied in the field of nanomaterials, can solve problems such as complex processes, and achieve the effects of simple processes, rapid diffusion, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation method of described graphene oxide dispersion liquid is as follows:

[0071] (1) Take by weighing 7.5g potassium permanganate and 1.5g graphite powder, grind 2h under 300r / min rotating speed condition in ball mill;

[0072] (2) Slowly add the above grinding mixture into a three-necked flask containing 115mL of sulfuric acid and 40mL of phosphoric acid in an ice bath, and react at 34-36°C for 2h;

[0073] (3) Measure 230mL deionized water and pour it into the dropping funnel, slowly add deionized water dropwise to the above-mentioned three-neck flask, control the temperature below 50°C, and complete the dropwise addition within 2 hours;

[0074] (4) After adding water, react at 34-36°C for 2 hours;

[0075] (5) Stop stirring, pour the reaction solution into a 1L beaker, and then add 700mL of H 2 O, stir well with a glass rod, slowly add 12.5mL (30%) H 2 o 2 , react for 10-15min;

[0076] (6) Centrifugal filtration, the material in the lower layer was...

Embodiment 1

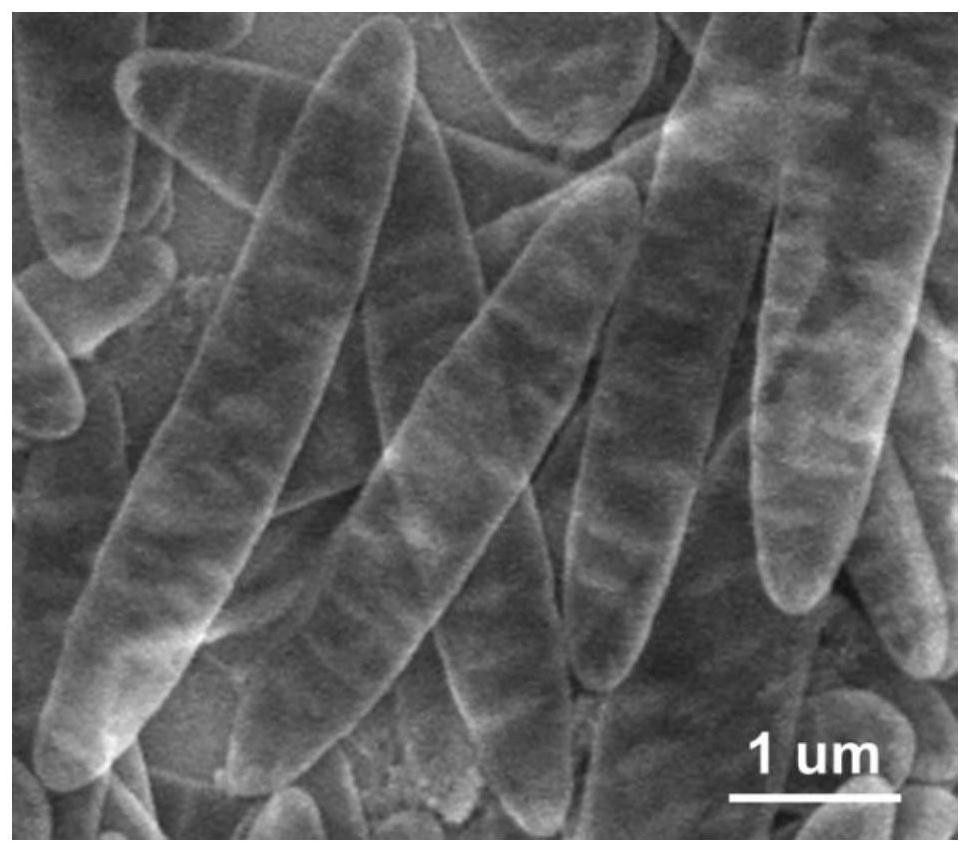

[0150] (1) Preparation of rough-surfaced polymer sheets

[0151] A. Weigh 20mg of surfactant F127, 12mg of hydrophobic stearic acid and 20g of water, add them to the reactor, raise the temperature to 80°C, stir for 4h, cool down to 40°C, and let stand for 24h to obtain a two-dimensional nanosheet colloid template solution;

[0152] B. According to the volume ratio of ethanol / water is 2:1 configuration 300g ethanol / water mixture, join in the reaction kettle, then weigh 101mg terephthalaldehyde, 126mg phloroglucinol and 10g above-mentioned colloidal template solution, add in sequence In the reaction kettle, stir for 30min;

[0153] C. Measure 0.1mL of 0.4mol / L phenylenediamine solution into the reaction kettle and stir for 15min;

[0154] D. Turn on the reflux device and react at 80°C for 4 hours;

[0155] E. Centrifuge the above reaction product under the condition of 8000r / min, wash and dry to obtain a polymer sheet with a rough surface.

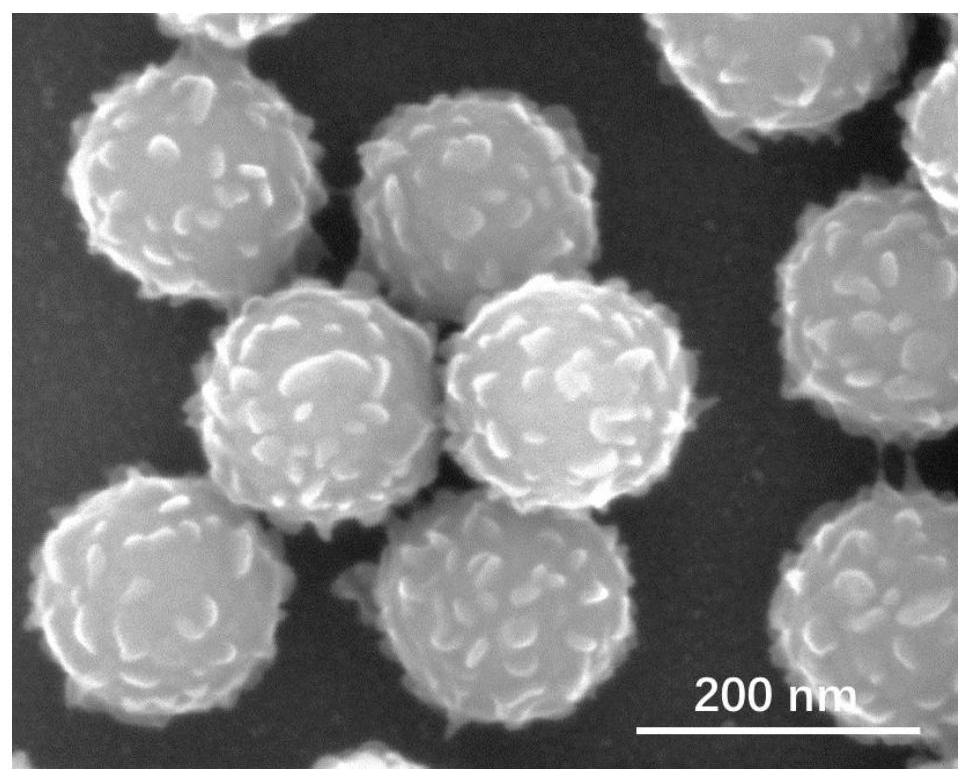

[0156] (2) Preparation of carbon ...

Embodiment 2

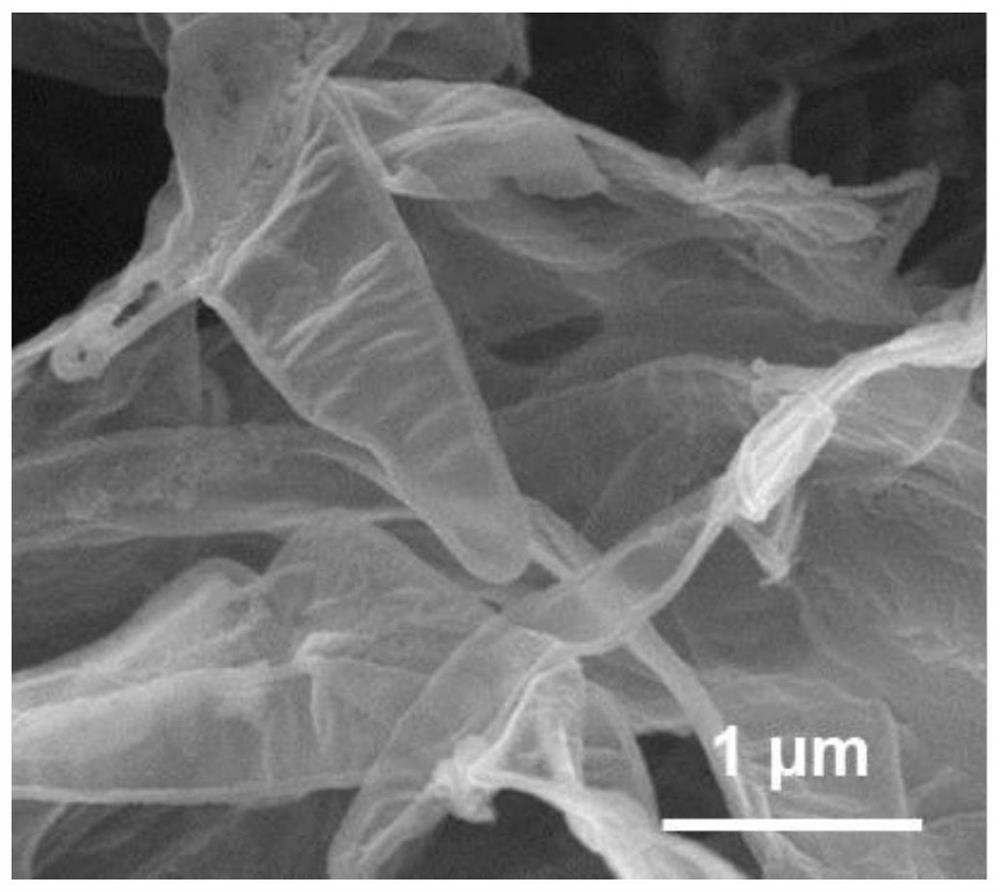

[0161] (1) Preparation of rough-surfaced polymer sheets

[0162] A. Weigh 15mg of surfactant P123, 10mg of hydrophobic boron nitride and 30g of water, add them into the reactor, raise the temperature to 70°C, stir for 6h, cool down to 30°C, and let stand for 24h to obtain a two-dimensional nanosheet colloid template solution;

[0163] B. Take 300g of water and add it to the reaction kettle, then weigh 92mg of isophthalaldehyde, 151mg of phloroglucinol and 15g of the above-mentioned colloidal template solution, add them to the reaction kettle in turn, and stir for 60min;

[0164] C. Measure 0.3mol / L benzidine 0.5mL solution into the reaction kettle and let stand for 30min;

[0165] D. Turn on the reflux device and react at 100°C for 6 hours;

[0166] E. Centrifuge the above reaction product under the condition of 8000r / min, wash and dry to obtain a polymer sheet with a rough surface.

[0167] (2) Preparation of carbon nanosheets with rough surface

[0168] Put the rough-sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com