Truss framework composite material product, and flowing medium forming mould and forming method thereof

A composite material and flow medium technology, applied in the direction of layered products, etc., can solve the problems of high mold cost and complex molding processing, and achieve the effects of accelerating the speed of replacement, reducing manufacturing costs, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

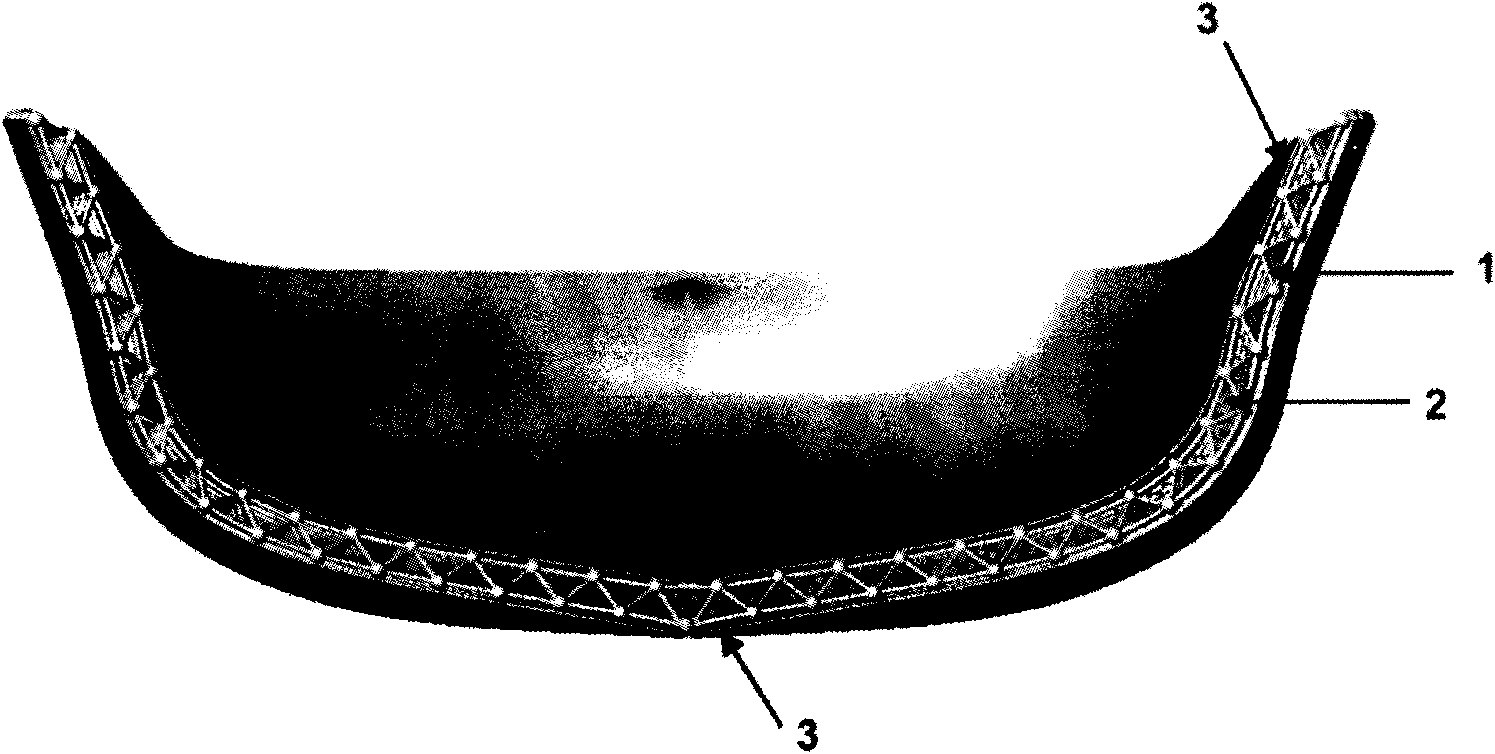

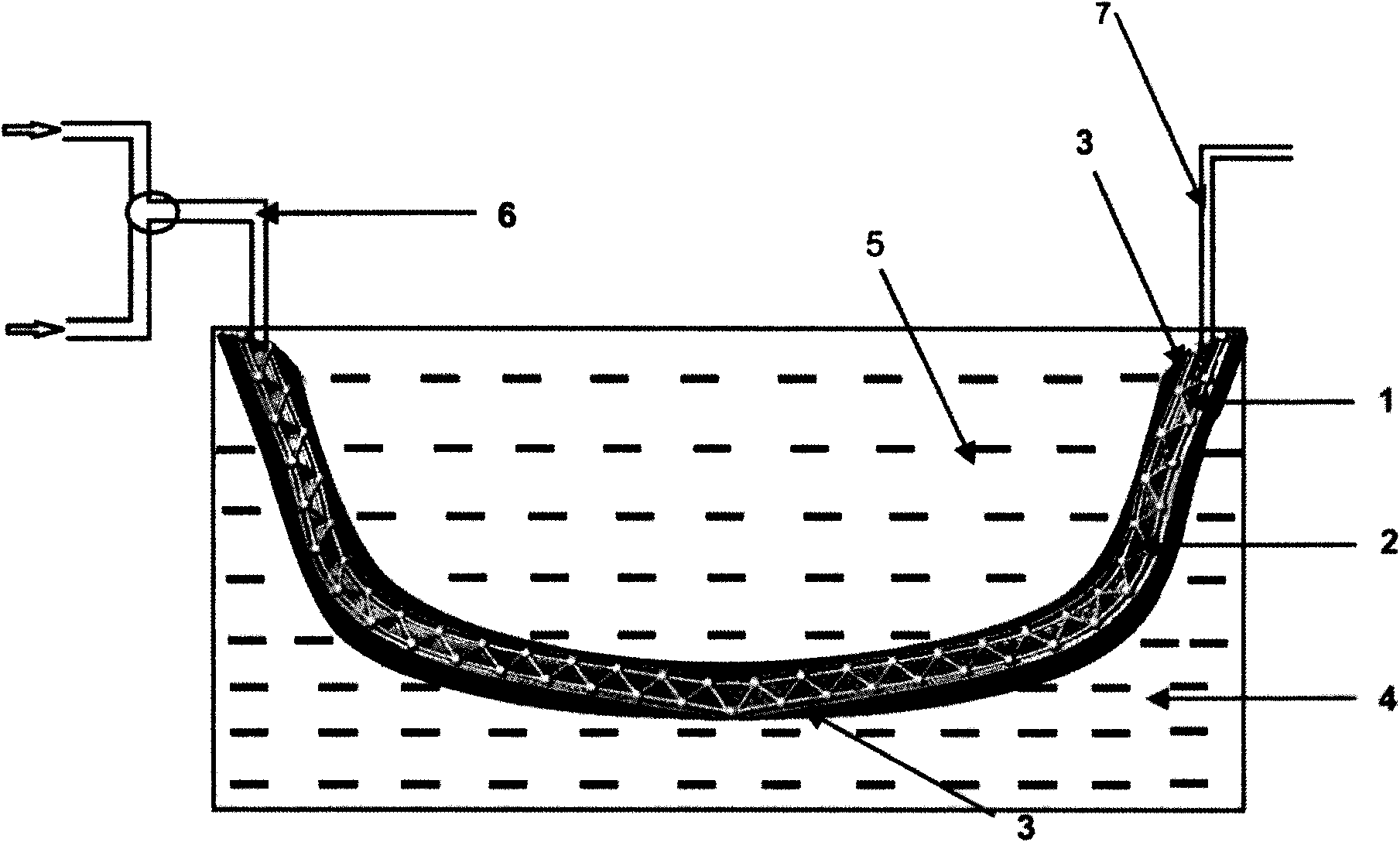

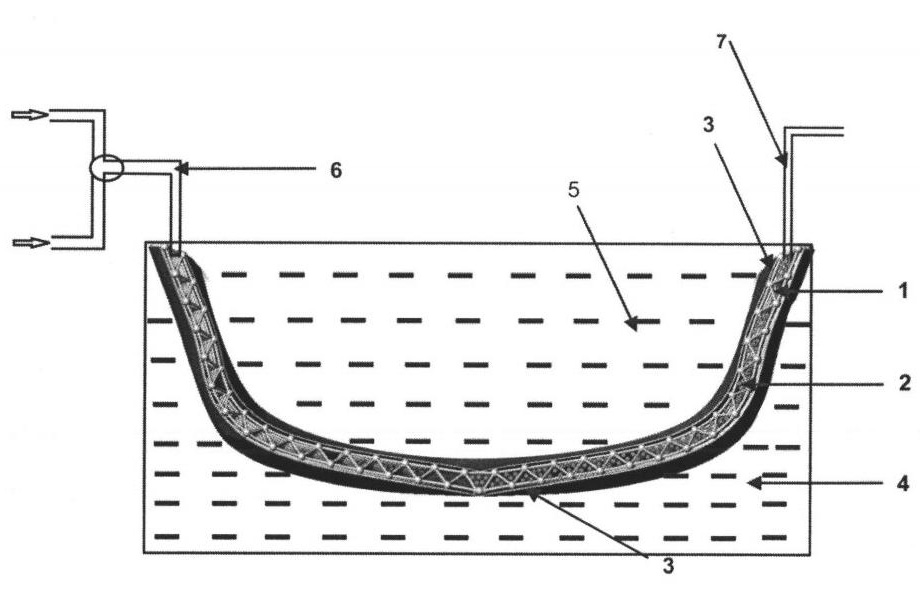

[0018] Example: Forming of a yacht hull

[0019] The yacht hull is made of stainless steel wire as the skeleton material 1, polyurethane rubberized cloth as the skin material 3, and glass fiber reinforced plastic resin as the filling material 2.

[0020] The molding die for the above-mentioned yacht hull is connected by stainless steel wires to form a skeleton material 1, and polyurethane rubberized cloth is used as a skin material 3 to be pasted on the nodes of the stainless steel wire as the outline of the above-mentioned yacht hull to form a mold cavity, and the container is a pool with an open structure. The cavity is placed in the container, the upper side of the cavity is the inner side of the yacht hull, the lower side of the cavity is the outer side of the yacht hull, the inner side and the outer side of the yacht hull are in contact with the inner surface flow medium 5 and the outer surface flow medium 4 respectively, and the inner surface flows Both the medium 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com