Water lifting and white smoke removal device and water lifting and white smoke removal method thereof

A technology for extracting water and mist from flue gas, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of high moisture content in flue gas at the outlet, high investment costs, waste of water resources, etc., and achieve low investment , Small footprint and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

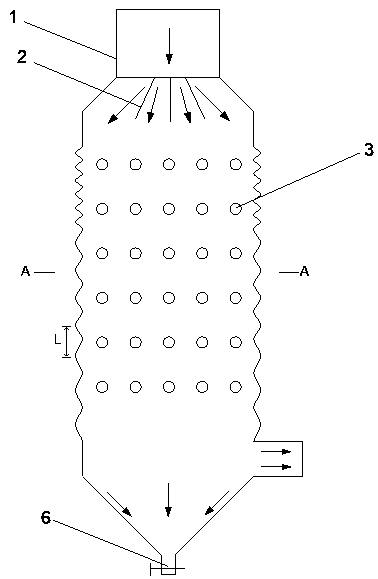

[0041] Such as figure 1 , figure 2 As shown, a water-lifting and whitening device includes a bellows-type casing 4, a flue gas inlet 1 is provided on the top of the bellows-type casing 4, and a plurality of flue gas splitter plates 2 are connected to the lower end of the flue gas inlet 1. The bottom of the bellows type housing 4 is conical, and the bottom end of the conical part is the drain port 6 . The bellows type shell 4 is provided with a smoke outlet 5 close to the upper port of the conical part.

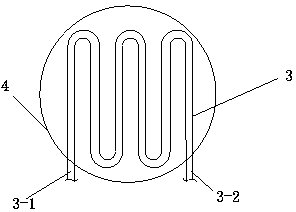

[0042] Several sets of flue gas heat exchange tubes 3 are densely arranged between the flue gas distribution plate 2 and the flue gas outlet 5; each set of flue gas heat exchange tubes 3 is provided with a cooling water inlet 3-1 and a hot water exchange outlet 3-2. The cooling water inlet 3-1 extends from the outside of the bellows type shell 4 to the inside of the bellows type shell 4, and is sealed with the bellows type shell 4; The inside of 4 extends out of the bellow...

Embodiment 2

[0055] As another embodiment, the height of the shell between the lower end of the flue gas distribution pipe 2 and the flue gas outlet 5 is about 26.6 meters, and the internode pitch of the bellows type shell 4 has an equal difference from 2 to 5 cm along the direction of flue gas travel. The sequence increases; the internode spacing is set as follows: 2.00cm, 2.04cm, 2.08cm, 2.16cm...5.00cm from top to bottom.

[0056] According to the formula, the node spacing is calculated according to different flue gas treatments. Generally, the node spacing of the bellows shell is 2-6cm. In special cases, special designs can also be made according to the present invention and formulas.

[0057] Other structures of embodiment 2 are the same as embodiment 1.

[0058] The above high-temperature flue gas can be high-temperature flue gas to be dewatered and whitened in production devices in the fields of metallurgy, chemical industry, steel, thermal power, etc. The specific application of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com