Method for recycling lead and mercury from acidic wastewater

A technology for acidic wastewater and wastewater, applied in the field of mercury and lead recovery, can solve the problems of affecting the mercury grade in sludge, secondary pollution, and the difficulty of separating heavy metal wastewater one by one, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

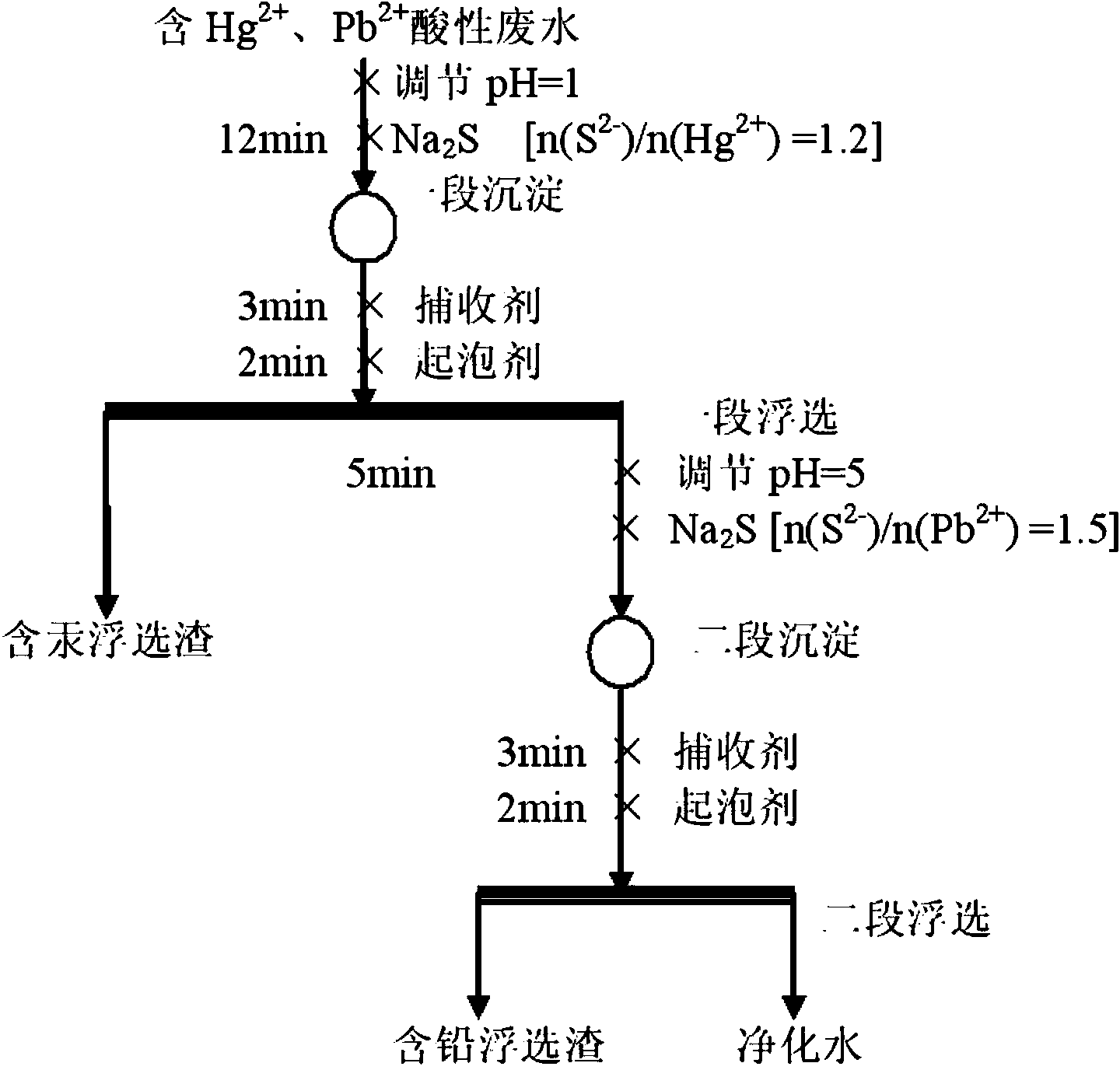

Embodiment 1

[0021] Hg at pH 1.0 2+ , Pb 2+ For waste water with a concentration of 10mg / L, add n(S 2- ) / n(Hg 2+ ) is sodium sulfide of 1.2, maintain the pH value, react at a rotating speed of 200r / min for 12min, then pour it into the flotation tank, add butylammonium black medicine and terpineol to float and reclaim the mercury residue. The wastewater after a stage of flotation is then adjusted to a pH value of 5.0, adding n(S 2- ) / n(Pb 2+ ) is 1.5 sodium sulfide, stirred at 200r / min for 12min and then poured into the flotation tank, adding butyl ammonium black medicine and terpineol to recover lead slag. Residual Pb in wastewater after secondary flotation 2+ The concentration is less than 0.20mg / L, Hg 2+ The concentration is less than 0.01mg / L, and the pH is about 8; the grade of mercury in the first-stage flotation slag is 79.45%, and the lead grade in the second-stage flotation slag is 84.20%. After drying, the scum can be sold as mercury products and lead products respectively ...

Embodiment 2

[0023] Hg at pH 1.5 2+ , Pb 2+ For wastewater with a concentration of 100mg / L, add n(S 2- ) / n(Hg 2+ ) is sodium sulfide of 1.1, maintain the pH value, react at a rotating speed of 300r / min for 10min, and then pour it into a flotation tank, add butyl ammonium black medicine and terpineol to float and reclaim mercury residue. The wastewater after one stage of flotation is then adjusted to a pH value of 4.0, adding n(S 2- ) / n(Pb 2+ ) is 1.5 sodium sulfide, stirred at a rotating speed of 180r / min for 14min and then poured into the flotation tank, adding butyl ammonium black medicine and terpineol to recover lead slag. Residual Pb in wastewater after secondary flotation 2+ The concentration is less than 0.20mg / L, Hg 2+ The concentration is less than 0.01mg / L, and the pH is about 7; the grade of mercury in the first-stage flotation slag is 79.85%, and the lead grade in the second-stage flotation slag is 84.38%. After drying, the scum can be sold as mercury products and lead pr...

Embodiment 3

[0025] Hg at pH 1.2 2+ , Pb 2+ For wastewater with a concentration of 200mg / L, add n(S 2- ) / n(Hg 2+ ) is sodium sulfide of 1.2, maintain the pH value, react at a rotating speed of 200r / min for 12min, then pour it into the flotation tank, add butylammonium black medicine and terpineol to float and reclaim the mercury residue. The wastewater after one stage of flotation is then adjusted to a pH value of 4.0, adding n(S 2- ) / n(Pb 2+) is 1.5 sodium sulfide, stirred at 200r / min for 12min and then poured into the flotation tank, adding butyl ammonium black medicine and terpineol to recover lead slag. Residual Pb in wastewater after secondary flotation 2+ The concentration is less than 0.20mg / L, Hg 2+ The concentration is less than 0.01mg / L, and the pH is about 7; the grade of mercury in the first-stage flotation slag is 79.42%, and the lead grade in the second-stage flotation slag is 83.45%. After drying, the scum can be sold as mercury products and lead products respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com