A kind of non-molybdenum sulfide ore flotation inhibitor and its application

A technology for sulfide ore and inhibitor, applied in flotation, solid separation, etc., can solve the problems of high price, unstable chemical properties, and no commercial application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

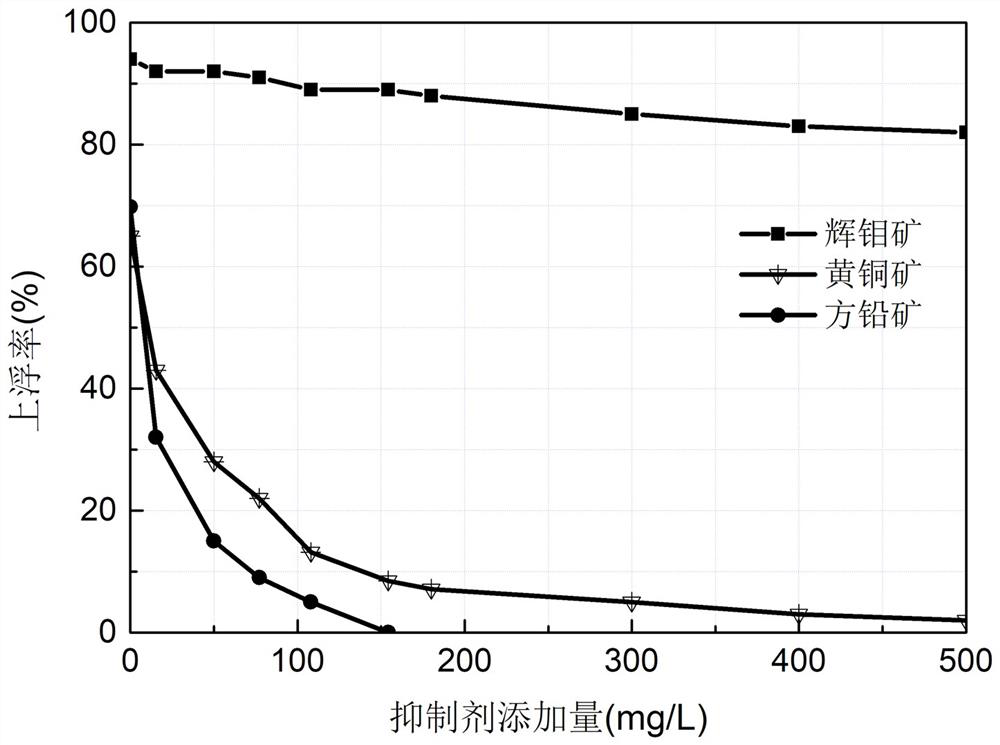

[0028] Take 2g of molybdenite, chalcopyrite, and galena single minerals with a particle size of +38-74μm for flotation respectively, take 50mL of distilled water and add it to a 70mL hanging tank flotation machine, and stir at a speed of 1300r / min to adjust the slurry , so that the slurry is fully dispersed.

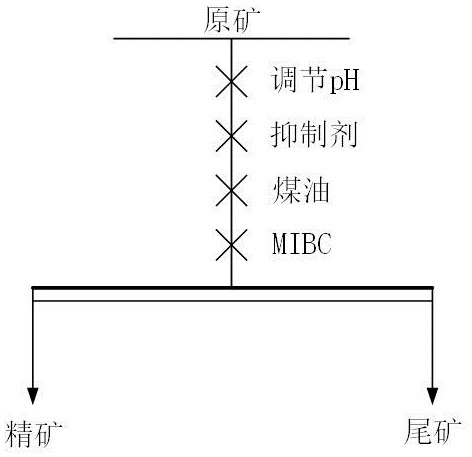

[0029] The order of adding the medicaments is as follows: figure 1 As shown, the pH of the ore pulp was adjusted to 9 before adding the chemical agent, and the DL-dithiothreitol concentration was 0, 15.4, 50, 77.1, 108, 154, 180, 300, and 400, respectively , 500mg / L. After the stirring is completed, air flotation is carried out to obtain foam products and tailings.

[0030] Filter, dry and weigh the foam product and tailings respectively, and calculate the floating rate, the result is as follows: figure 2 shown.

[0031] It can be seen from the examples that the inhibitor has almost no inhibitory effect on molybdenite, but has good inhibitory ability on chalcopyrite...

Embodiment 2

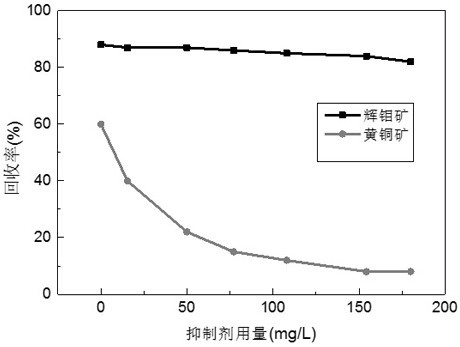

[0033] Take 1g of +38-74μm molybdenite and chalcopyrite single minerals and mix evenly at a ratio of 1:1, take 50mL of distilled water and add it to a 70mL hanging tank flotation machine, and stir at a speed of 1300r / min to adjust the slurry , so that the slurry is fully dispersed.

[0034] The order of adding the medicaments is as follows: figure 1 As shown, the pH of the pulp was adjusted to 9 before adding the chemical agent, and after adding the chemical agent, it was stirred for 5 minutes, 3 minutes, and 2 minutes in sequence. After the stirring is completed, air flotation is carried out to obtain foam products and tailings. Dry the foam product and tailings separately, weigh and test the content of copper and molybdenum in the concentrate, and calculate the recovery rate of copper and molybdenum. The result is as image 3 shown.

[0035] It can be seen from the examples that the inhibitor can achieve a very good copper-molybdenum separation effect when the dosage is ...

Embodiment 3

[0037] Take 1g of +38-74μm molybdenite and galena single minerals and mix evenly at a ratio of 1:1, take 50mL of distilled water and add it to a 70mL hanging tank flotation machine, and stir at a speed of 1300r / min to adjust the slurry , so that the slurry is fully dispersed.

[0038] The order of adding the medicaments is as follows: figure 1 As shown, the pH of the pulp was adjusted to 9 before adding the chemical agent, and after adding the chemical agent, it was stirred for 5 minutes, 3 minutes, and 2 minutes in sequence. After the stirring is completed, air flotation is carried out to obtain foam products and tailings. Dry the foam product and tailings separately, weigh and test the content of lead and molybdenum in the concentrate, and calculate the recovery rate of lead and molybdenum. The result is as Figure 4 shown.

[0039] It can be seen from the examples that the inhibitor can achieve effective flotation separation of lead and molybdenum under the condition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com