A kind of method that uses chelation inhibitor PBTCA to carry out phosphate rock flotation to remove magnesium

A phosphate rock and inhibitor technology, which is applied in the field of phosphate rock positive flotation and magnesium flotation, can solve the problem of high MgO content in phosphate rock concentrate, which restricts the development and utilization of phosphate rock resources, Exacerbating the excessive consumption of phosphating chemical acid and other problems, achieving the effect of simple process method, reduced equipment corrosion maintenance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

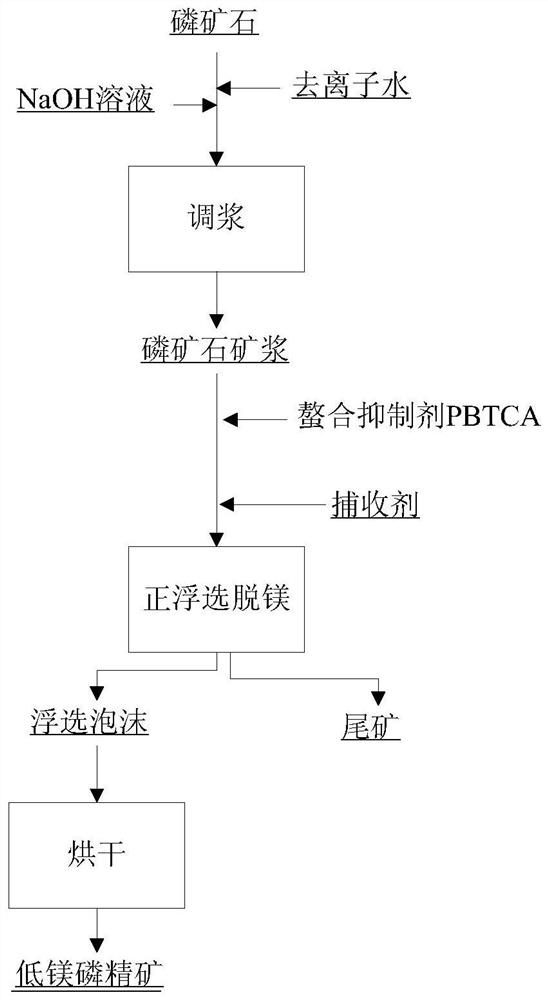

[0038]A kind of method that carries out phosphate rock flotation magnesium removal with chelating inhibitor PBTCA, its process flow chart is as figure 1 Shown, comprise the step of following phosphate rock flotation demagnesification:

[0039] Step 1: Blending

[0040] At 20°C, put the phosphate rock in the flotation cell of the XFGII hanging cell flotation machine, add deionized water, wherein, the phosphate rock and deionized water are mixed at a mass ratio of 1:6, and the impeller speed is Stirring and pulping at 1800rpm for 2 minutes; then adding a pH regulator NaOH aqueous solution with a mass percent concentration of 0.5% to the obtained phosphate rock slurry to adjust the pH value of the phosphate rock pulp to 8, and then stirring and pulping for 2 minutes;

[0041] Step 2: Magnesium removal by positive flotation

[0042] Add the chelation inhibitor PBTCA solution with a mass concentration of 2g / L to the phosphate rock slurry with a pH value of 8. The amount of the ch...

Embodiment 2

[0047] A kind of method that carries out phosphate rock flotation magnesium removal with chelating inhibitor PBTCA, comprises the step of following phosphorus rock flotation magnesium removal:

[0048] Step 1: Blending

[0049] At 25°C, the phosphate rock was placed in the flotation cell of the XFGII hanging cell flotation machine, and deionized water was added, wherein the phosphate rock and deionized water were mixed at a mass ratio of 1:6, and the impeller speed was Stirring and pulping at 1900rpm for 2 minutes; then adding a pH regulator NaOH aqueous solution with a mass percent concentration of 1.5% to the obtained phosphate rock slurry to adjust the pH value of the phosphate rock pulp to 9.5, and then stirring and pulping for 2 minutes;

[0050] Step 2: Magnesium removal by positive flotation

[0051] Add the chelation inhibitor PBTCA solution with a mass concentration of 2g / L to the phosphate rock slurry with a pH value of 9.5. The amount of the chelation inhibitor PBT...

Embodiment 3

[0056] A kind of method that carries out phosphate rock flotation magnesium removal with chelating inhibitor PBTCA, comprises the step of following phosphorus rock flotation magnesium removal:

[0057] Step 1: Blending

[0058] At 20°C, put the phosphate rock in the flotation cell of the XFGII hanging cell flotation machine, add deionized water, wherein, the phosphate rock and deionized water are mixed at a mass ratio of 1:6, and the impeller speed is Stirring and pulping at 2100rpm for 2 minutes; then adding a pH regulator NaOH aqueous solution with a mass percentage concentration of 3% to the obtained phosphate rock slurry to adjust the pH value of the phosphate rock pulp to 11.5, and then stirring and pulping for 2 minutes;

[0059] Step 2: Magnesium removal by positive flotation

[0060] Add the chelation inhibitor PBTCA solution with a mass concentration of 2g / L to the phosphate rock slurry with a pH value of 8. The amount of the chelation inhibitor PBTCA accounts for 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com