Horizontal grinding mill with built-in classifying turbine

A grading impeller and grinding machine technology, applied in mechanical equipment, engine components, engine seals, etc., can solve the problems of shortening the residence time of ore particles, no fundamental changes, and limiting large-scale, so as to avoid over-crushing phenomenon , improve the degree of activity, increase the effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

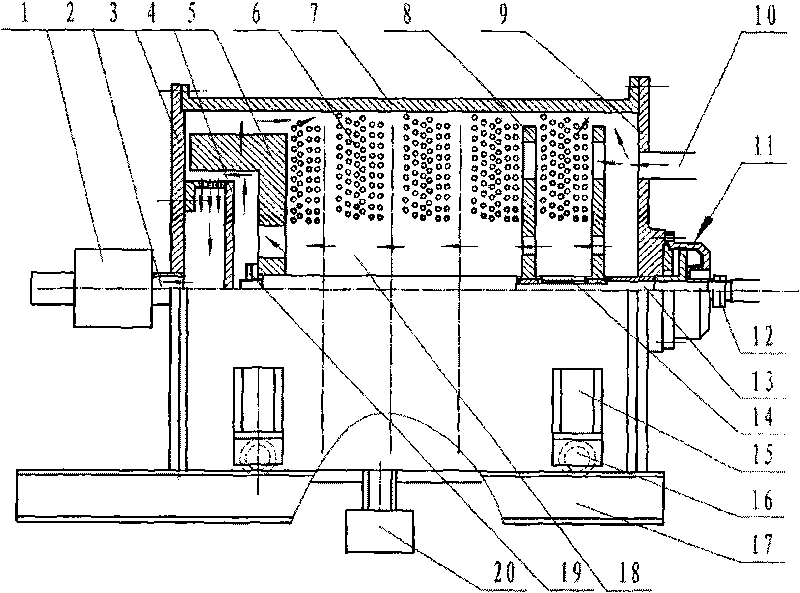

[0031] A horizontal grinding machine with a built-in classifying impeller. Its structure is as figure 1 As shown: the installation center line of the grinding chamber 18 is horizontal, the inner surface of the grinding chamber 18 is lined with wear-resistant materials, the grinding medium 6 is installed in the grinding chamber 18, and the medium discharge valve 20 is installed in the middle of the bottom of the cylinder 7 for maintenance When the grinding media discharge. The ore feeding pipe 10 is located above the right end cover 9 of the grinding chamber 18, and the ore discharge pipe 2 communicates concentrically with the grinding chamber 18 through the left end cover 3, and the ore discharge pipe 2 is equipped with a discharge valve 1. The cylinder 7 is placed on the track 17 through four brackets 15 and its supporting rollers 16. The length of the cylinder 7 is 1.5 to 2.0 times its diameter; the left end cover 3 of the grinding chamber 18 is fixed with a fairing 4 .

...

Embodiment 2

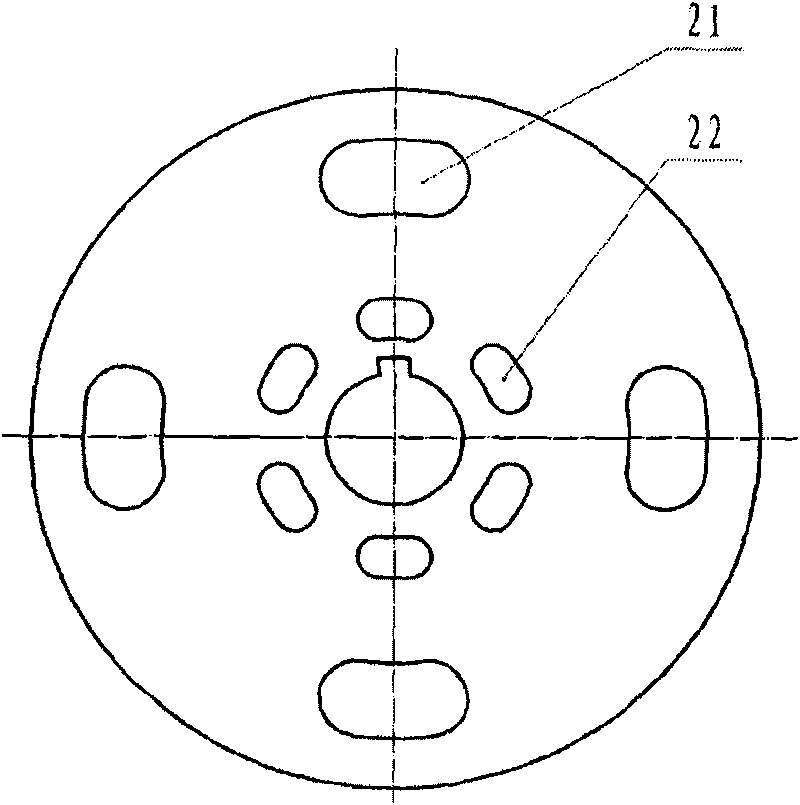

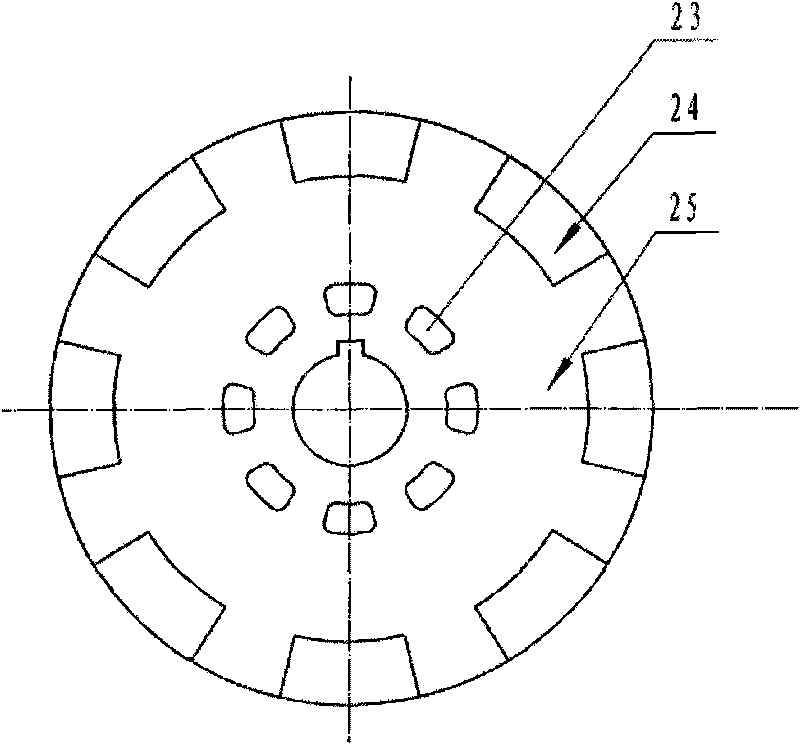

[0041] A horizontal grinding machine with a built-in classifying impeller. The length of the cylinder 7 is 2.0 to 2.5 times its diameter; the number of stirring impellers 8 installed on the main shaft 13 is 6 to 8; the grinding medium 6 is a standard glass ball, a standard high alumina ceramic ball, natural ore, river sand One of them, the filling volume of the grinding medium 6 is 2 / 3 to 3 / 4 of the volume of the cylinder 7; the cylindrical wall of the fairing 4 is evenly opened with 60 to 120 sieve holes 26; the classifying impeller There are 6~7 or 9~10 waist-shaped holes 23 near the center of the flat plate 25 of 5, and the periphery of the flat plate 25 is provided with 6~7 or 9~10 trapezoidal bosses 24; There are 5-6 holes 21 with the same size, and 7-8 waist-shaped holes 22 in the inner ring with the same size; the cylinder body 7 is composed of two semi-cylinders.

[0042] All the other are with embodiment 1.

[0043] In this specific embodiment, the main shaft 13 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com