Plastic grinder for plastic product processing

A plastic product and grinding machine technology, applied in the field of plastic processing, can solve problems such as unstable fixation, a large amount of plastic dust, and easy slipping, and achieve the effect of avoiding floating around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

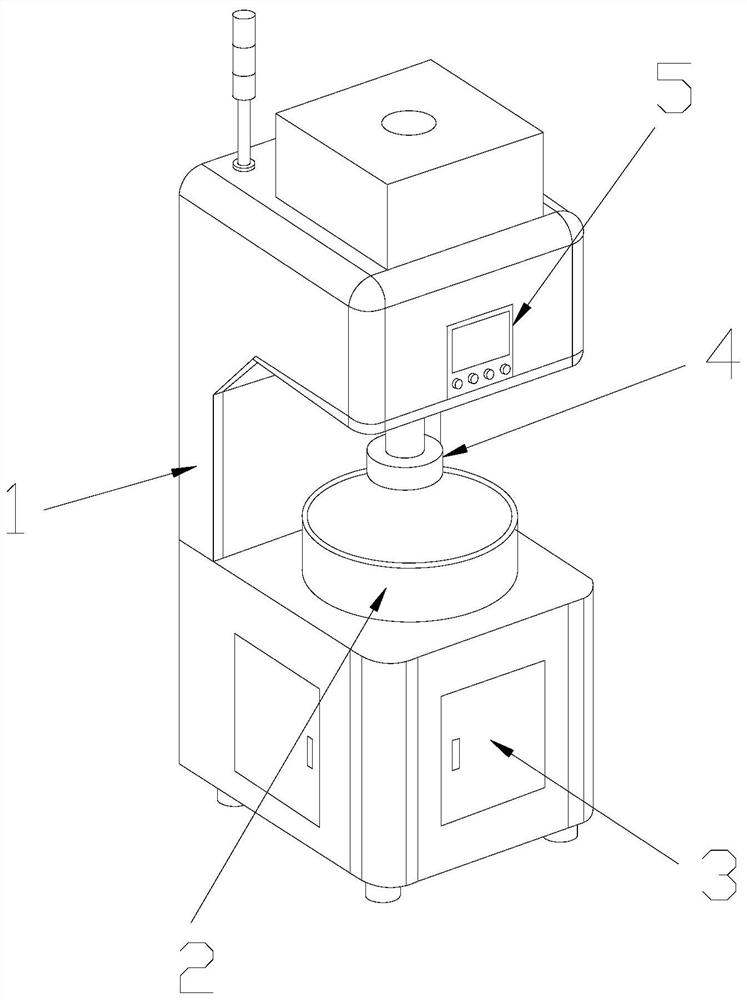

[0030] see Figure 1-Figure 4 , the present invention provides a plastic grinding machine for processing plastic products, the structure of which includes a grinding machine 1, a grinding workbench 2, a machine door 3, a fixing device 4, and an operation panel 5, and a grinding machine is installed in the middle of the grinding machine 1. Workbench 2, a machine door 3 is provided under the surface of the front end of the grinding machine 1, the grinding machine 1 and the machine door 3 are connected by hinges, and a fixing device 4 is provided on the inner top of the grinding machine 1, and the The grinding machine 1 is movably connected with the fixing device 4, and an operation panel 5 is installed on the top surface of the grinding machine 1;

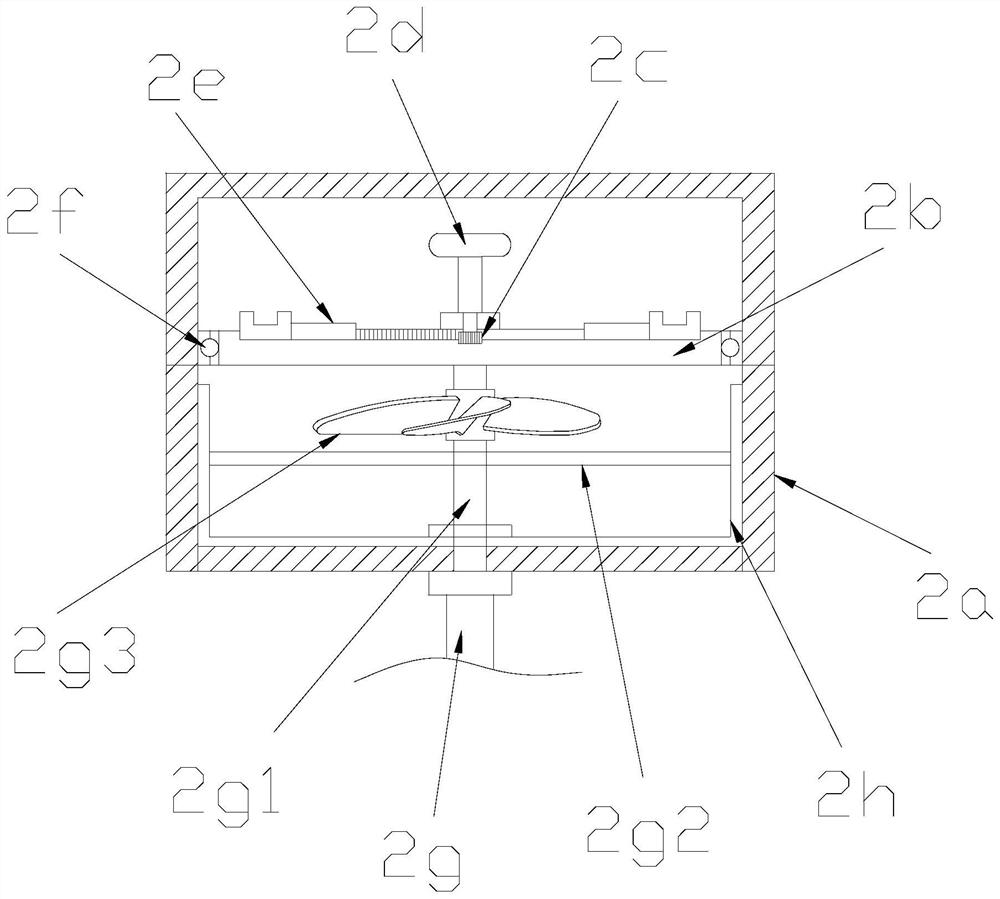

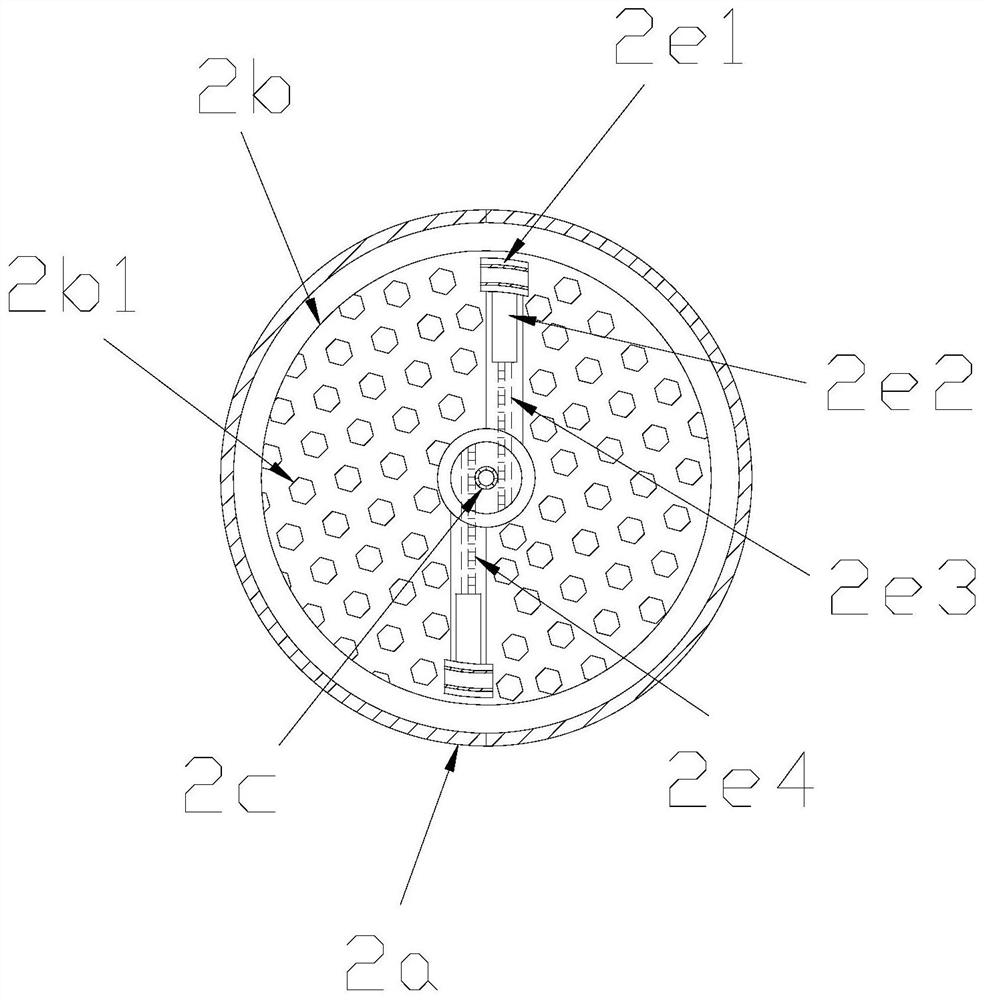

[0031] The grinding table 2 is composed of a machine cover 2a, a working rotating plate 2b, a driving gear 2c, a rotating rod 2d, an adjustable grinding mechanism 2e, a bearing ring 2f, a drive motor 2g, and a waste recycling box 2h....

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a plastic grinding machine for processing plastic products. The overflow prevention mechanism 2g2 is composed of a rotating disk 2g21, a closing piece 2g22, a dust collection hole 2g23, a storage groove 2g24, a mounting ring 2g25, and a spring 2g26. Four dust collection holes 2g23 are equidistantly distributed on the top surface of the rotary disk 2g21, and four storage slots 2g24 are equidistantly distributed inside the rotary disk 2g21, and the storage slots 2g24 are connected with the dust collection holes 2g23. A closing piece 2g22 is provided in the receiving groove 2g24, the rotating disk 2g21 is connected with the closing piece 2g22 through a spring 2g26, and a mounting ring 2g25 is installed in the middle of the rotating disk 2g21.

[0041] Four arc-shaped guiding pieces j2 are equidistantly distributed on the top surface of the rotating disk 2g21, and the rotating disk 2g21 and the arc-shaped guiding piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com