Grinding machining system

A processing system and pulverizer technology, applied in feed, grain processing, food science, etc., can solve the problems of increased pulverizing processing cost, increased pulverizing processing energy consumption, and increased screen wear, etc., to reduce excessive pulverization and improve Screening efficiency, the effect of preventing excessive crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

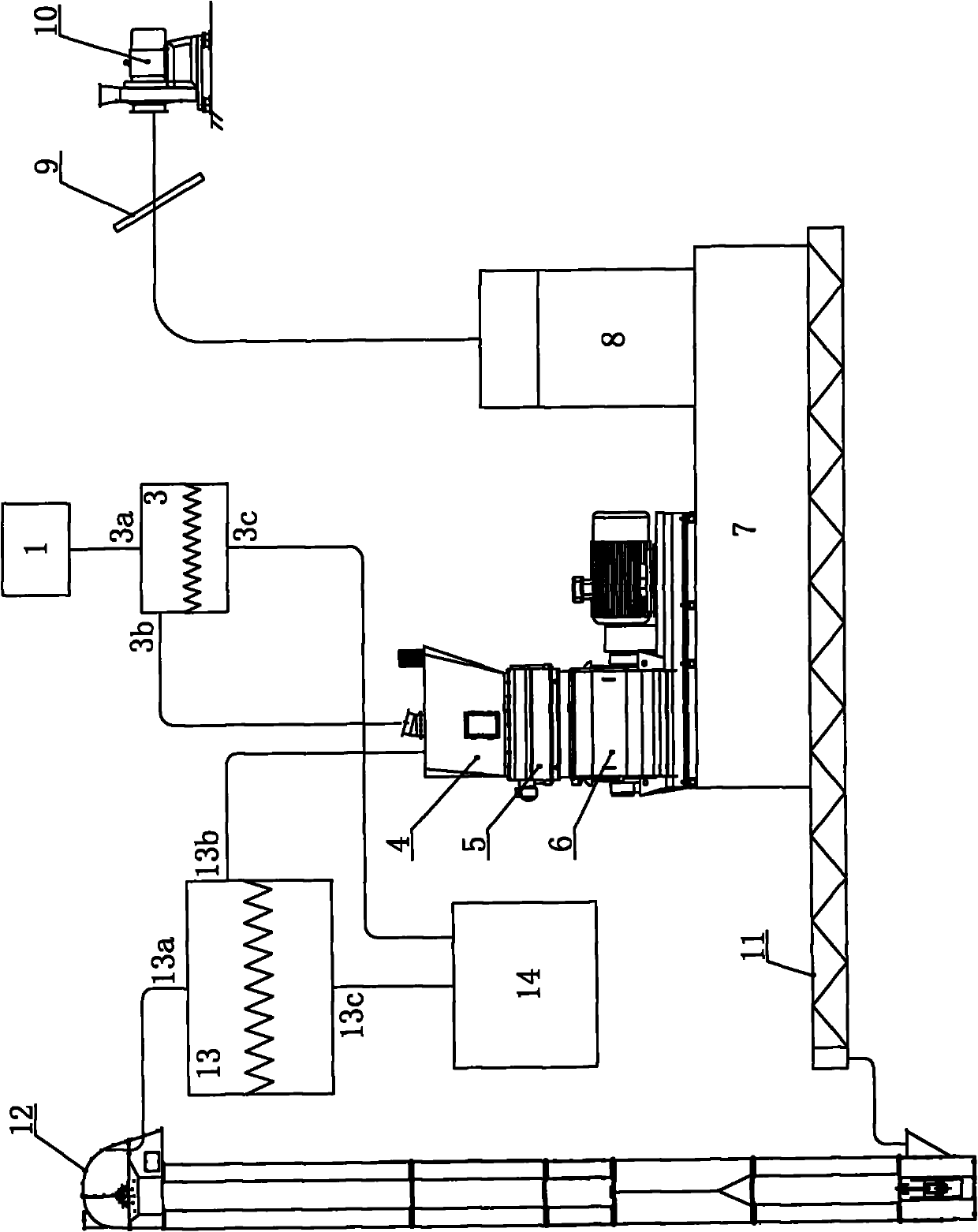

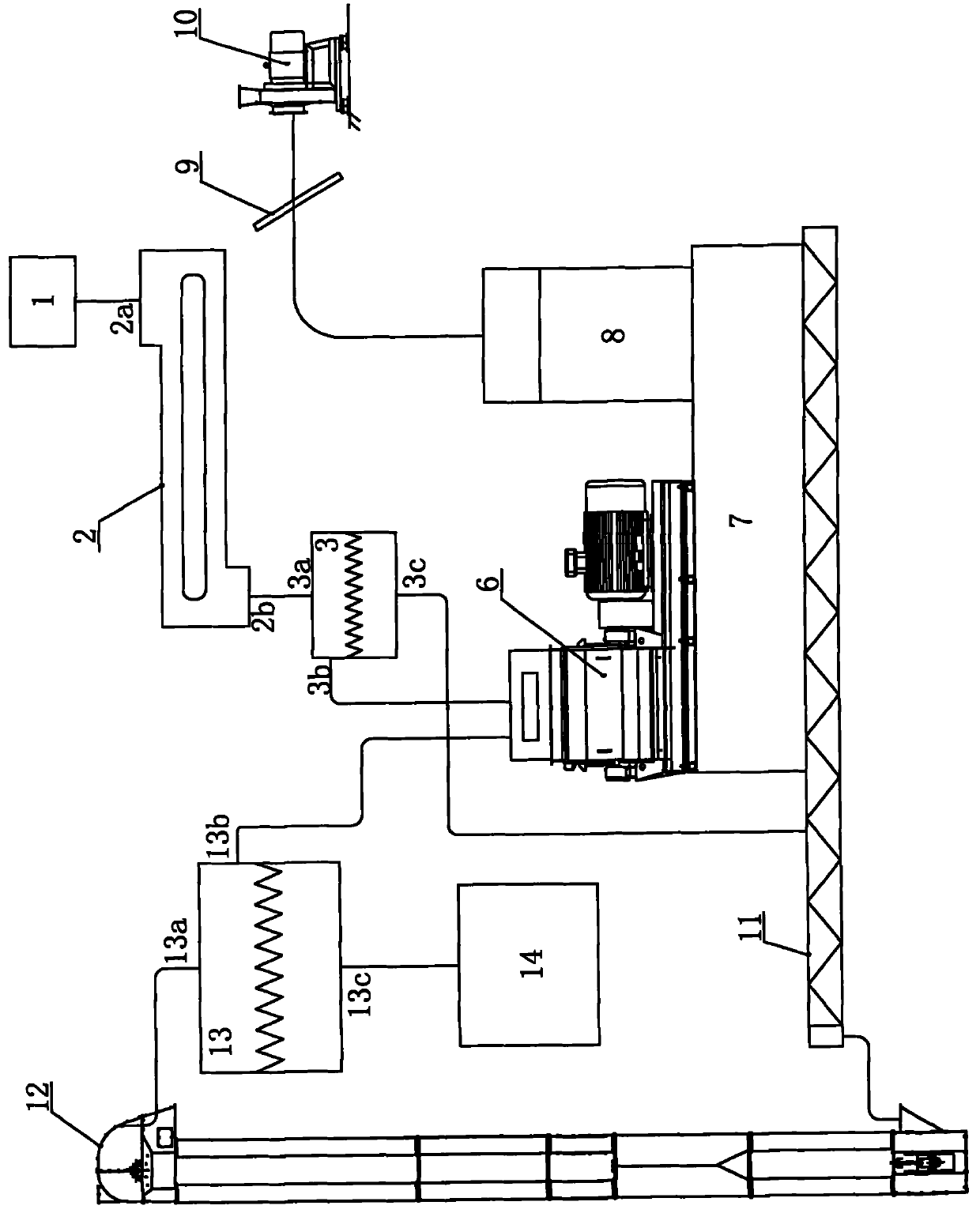

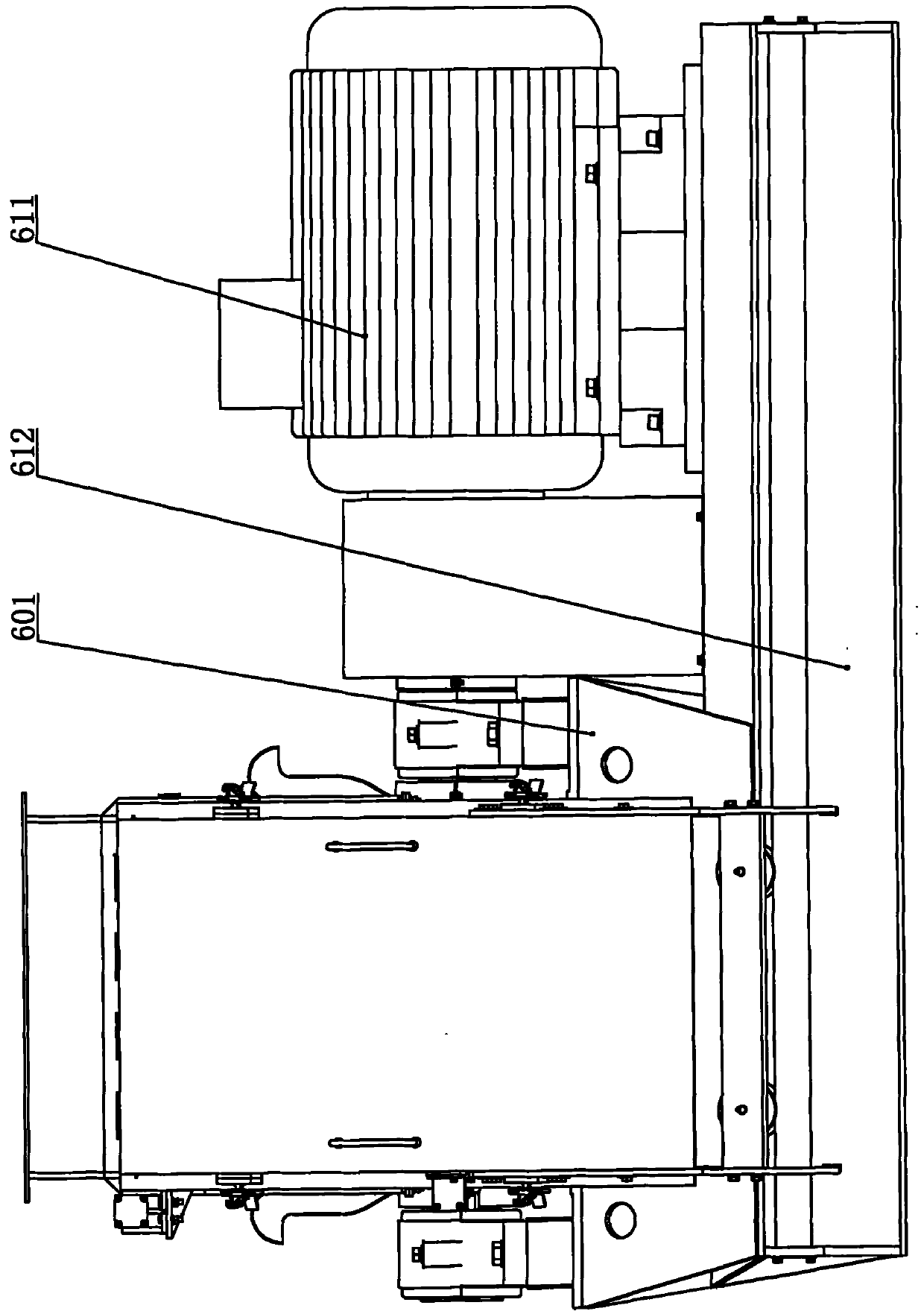

[0032] Embodiment 1 During production, the raw material 1 is first screened by the raw material sieve 3, so that the material with a small particle size directly passes through the raw material sieve 3 and enters the powder material collection bin, avoiding entering the pulverizer, preventing excessive crushing and increasing power consumption. The large particles on the raw material sieve 3 are sent to the raw material buffer bin 4, and are fed into the non-sieve pulverizer 6 by the feeder 5 according to the set feeding speed for pulverization. The crushed material enters the settling chamber 7, passes through the auger conveyor 11 and reaches the hoist 12, and after being lifted by the hoist 12, enters the powder sieve 13 for re-screening, and the fine particles whose particle size meets the requirements pass through the powder sieve 13 in time. Enter the powder collection bin. The oversized large particles that do not meet the requirements enter the pulverizer again for cru...

Embodiment 2

[0037] Embodiment 2 In production, the raw material 1 is sent to the raw material sieve 3 through the belt feeder for screening, so that the material with small particle size directly passes through the raw material sieve 3, leads to the discharge end of the auger conveyor 11, or directly enters the Powder silo. The large particles on the sieve of the raw material sieve 3 are sent to the sieveless pulverizer 6 for pulverization. The crushed material enters the settling chamber 7, passes through the auger conveyor 11 and reaches the hoist 12, and after being lifted by the hoist 12, enters the powder sieve 13 for re-screening, and the fine particles whose particle size meets the requirements pass through the powder sieve 13 in time. Enter the powder collection bin. The oversized large particles that do not meet the requirements enter the pulverizer again for crushing until they meet the requirements.

[0038] In the two embodiments, both the raw material sieve 3 and the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com